In this interview, AZoMaterials speaks with Dr. Kevin Matthews, regarding his work at the Warner lab of the University of Texas at Austin, and Dr. Seth Villarreal, Advanced Workflow Specialist at Leica Microsystems, about cryo vacuum workflows and their role in preserving battery interfaces for high-precision analysis.

Can you please introduce yourselves and your roles at CleanTech Analytics?

Dr. Kevin Matthews: Hello, I’m Kevin Matthews, a graduate researcher at the University of Texas at Austin, working under the guidance of Dr. Jamie Warner. My research centers on cryogenic electron microscopy, with a focus on uncovering the intrinsic structure and composition of sodium battery interfaces.

Dr. Seth Villarreal: I’m Seth Villarreal, and my role is to support the infrastructure and workflows that allow for delicate sample preservation using cryogenic and vacuum techniques. My focus is on building systems that move samples between instruments while preserving their structure and preventing environmental degradation.

What are cryo vacuum workflows, and why are they important for battery research?

Dr. Villarreal: These workflows are designed to move sensitive samples while minimizing thermal and atmospheric perturbations. In battery research, where even slight exposure to heat or air can alter the surface chemistry of a sample, cryo workflows preserve the sample in its original state. Liquid nitrogen, for example, acts as an active thermal buffer during transport. Vacuum environments prevent oxidation and contamination. The goal is to maintain the sample’s structure from preparation to imaging.

Dr. Matthews: From my side, cryo workflows are essential for preserving the true chemical and structural state of battery interfaces, especially when dealing with buried interfaces in intact cells. Traditional disassembly techniques disturb these structures. By integrating cryo transfer, we can image sodium cells without introducing artifacts, revealing more accurate degradation mechanisms.

Could you describe a typical cryo vacuum workflow in your lab?

Dr. Matthews: For me, a typical workflow starts with a battery coin cell - usually symmetric sodium cells in our case. After cycling, we plunge-freeze the intact cell in liquid nitrogen. This rapid cooling locks in the internal structure without triggering crystallization. Once frozen, we carefully remove the outer casing while maintaining cryogenic temperatures. We then use tools like the TIC 3X ion beam miller and the Scios DualBeam SEM/FIB - both equipped with cryo stages - to mill through the solid structure. From there, we either image the sample directly or perform a lamella lift-out for TEM analysis, all while keeping the sample at cryogenic temperatures.

Dr. Villarreal: All the transfer steps, from glovebox to cryo stage, are handled using specialized shuttles such as the Leica VCT that maintain vacuum and cold temperatures. These steps require careful planning to avoid warming. Even minor deviations in thermal control can destroy the integrity of a sample.

Why are battery interfaces considered to be "hard" to analyze with standard techniques?

Dr. Matthews: The main challenge is that the interfaces we’re most interested in are buried within the battery structure and are extremely reactive. As soon as you open the cell to study them, you risk disturbing those delicate layers.

The presence of liquid electrolytes adds another layer of complexity - they're not compatible with the high-vacuum conditions required for electron microscopy. Traditional disassembly methods tend to alter the composition and morphology of the SEI or the metal plating, which means you’re no longer looking at the true state of the system during operation. That’s where cryogenic techniques make a real difference - they let us capture these features closer to their native state.

How did cryo workflows lead to new discoveries in sodium battery degradation?

Dr. Matthews: One major finding was that degradation in symmetric sodium cells doesn't always occur through dendrite penetration, as previously thought. Instead, we saw evidence of infiltration through the separator.

By freezing intact cells and performing cross-sectional SEM imaging, we found significant sodium deposition on the electrode and within the separator itself. This behavior likely would have gone unnoticed if we had disassembled the cells in the glovebox. Keeping the interface intact with cryo workflows changed our understanding of failure modes in sodium batteries.

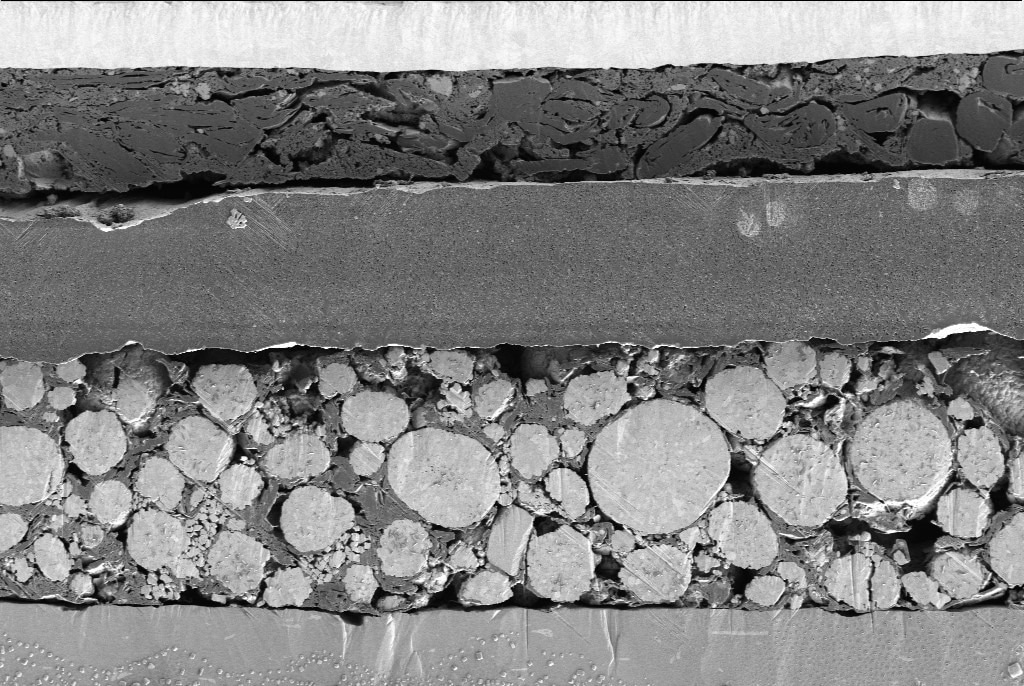

SEM imaging of Lithium-ion battery (LIB) cell with lithium-nickel-manganese-cobalt-oxide (NMC) cathode (top) and Graphite-on-copper foil anode (bottom). Polyethylene separator (PE) with ceramic coating visible in the middle. Image Credit: Prof Dr Ing Silke Christiansen, INAM eV, Forchheim, Germany.

What are some of the instruments and techniques involved in this workflow?

Dr. Villarreal: We tend to use a whole suite of tools, including the Leica VCM for sample mounting, the VCT shuttle for vacuum transfer, the Scios DualBeam for SEM and FIB milling, and the TIC 3X for large-scale polishing.

We also have specific holders that fit TEM grids for lamella prep and cryo TEM holders for imaging. Each tool serves a function, but must be fully integrated into a workflow that prevents warming or air exposure.

How do cryo techniques compare to traditional room-temperature disassembly methods?

Dr. Matthews: We did a side-by-side comparison. In one test, we disassembled a cell in a glovebox and froze it after removing the separator. In cryo SEM images, we still saw significant electro-deposited material on the separator, showing how much interface information is lost during manual separation. In contrast, our cryo-preserved intact samples allowed us to directly observe these interfaces, revealing structural features that would have been dismissed or missed entirely.

What advice would you give to researchers implementing cryo vacuum workflows for the first time?

Dr. Villarreal: First, you must understand that terminology varies between vendors and research groups. Make sure your team aligns on what “holder,” “shuttle,” or “transfer” means. Then, plan every step. Decide what aspects of the sample you’re trying to preserve and match the workflow to that.

Dr. Matthews: One piece of advice that I would give is not to underestimate training. These workflows involve many pieces of specialized equipment. Missteps in timing, handling, or transfer can destroy your sample. However, once optimized, the data quality is unmatched in terms of preserving the true electrochemical interface.

About Dr. Kevin Matthew

Dr. Kevin Matthews is a graduate researcher at the University of Texas at Austin, working in Dr. Jamie Warner’s group. His research focuses on cryogenic electron microscopy techniques to study battery materials, with an emphasis on sodium interfaces. He holds a BSc in Chemistry and has co-authored several studies on advanced battery characterization, particularly in imaging intact interfaces and modeling degradation pathways.

About Dr. Seth Villarreal

Dr. Seth Villarreal is an Advanced Workflow Specialist at Leica Microsystems. He earned his PhD in Pharmacology from Case Western Reserve University. In his role at Leica, Dr. Villarreal trains users and assists in optimizing workflows involving sample preparation and transfer for electron microscopy of temperature and contamination-sensitive samples.

This information has been sourced, reviewed and adapted from materials provided by Leica Microsystems GmbH .

For more information on this source, please visit Leica Microsystems GmbH .

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.