X-ray inspection is crucial in both the food and non-destructive testing sectors to guarantee quality and safety. Enhancing the detection of contaminants and defects requires minimizing noise in the captured images. To address this challenge, Hamamatsu Photonics has created a novel de-noising technology that combines deep learning algorithms with an innovative method for X-ray simulation.

General X-ray Noise Reduction Using Deep Learning

Deep learning, a branch of artificial intelligence (AI), imitates human thinking and learning by enabling computers to learn from data examples. At its foundation are ‘artificial neural networks,’ computational frameworks inspired by the brain’s neural connections.

Deep learning involves multiple hidden layers of neural networks that perform increasingly complex processing, where each layer processes input and passes refined information to the next. This layered structure allows the model to autonomously extract relevant features without manual intervention.

In this approach, a model can excel at classification tasks if provided with enough data, such as identifying cats in images. Similarly, it can learn to distinguish noise from structural elements in an X-ray image. The most challenging part is training the AI, which requires significant computational power and large datasets.

For X-ray image de-noising, tens of thousands of measured images may be necessary, which is a major limitation. As a result, overcoming this data demand often involves data augmentation or transfer learning strategies.

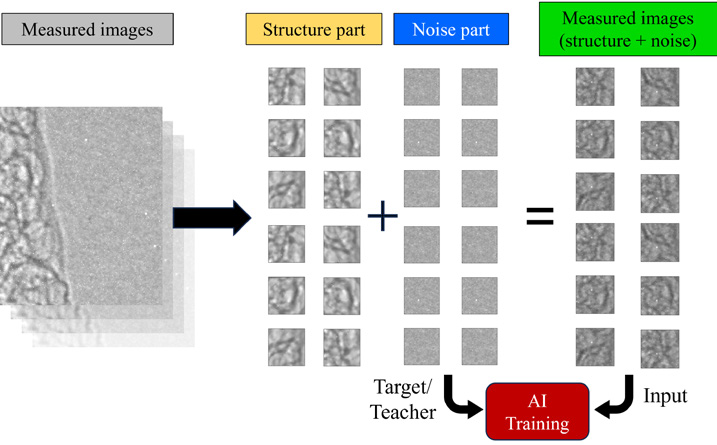

The training process typically begins with capturing images containing minimal noise. Different noise patterns are then artificially introduced to these clean images to create realistic, noisy inputs. These combined structure-plus-noise images serve as input, while the corresponding noise-only images act as teacher data for the AI to learn how to separate noise. This supervised learning framework enables the model to generalize well when applied to new, unseen data.

The resulting deep learning model can then predict noise in real measurement images. This explanation assumes the use of convolutional neural networks (CNN) for training; Figure 1 illustrates this training process.

A further limitation of relying solely on deep learning for de-noising is its dependency on consistent inspection parameters, such as the inspected product, X-ray energy, current, and the camera settings, all of which need to match those used during AI training.

To enhance the adaptability across X-ray inspection systems, merging deep learning with X-ray image simulation offers a promising path, reducing the need for extensive real image datasets.

Figure 1. Schematic representation of deep-learning algorithms training to obtain X-ray image de-noising. Image Credit: Hamamatsu Photonics Europe

X-ray Image Simulation

Hamamatsu Photonics’ proprietary X-ray simulation technology is founded on simulating four key elements of the inspection process:

- X-ray emission spectrum

- X-ray transmission through the object

- Scintillator response, which converts X-rays into visible light

- Sensor response, detecting visible light emitted by the scintillator

The simulation uses essential inputs such as a 3D model of the inspected object, the spatial coordinates of the X-ray camera and emission source, along with inspection settings like X-ray voltage, current, scintillator type, and sensor pixel size.

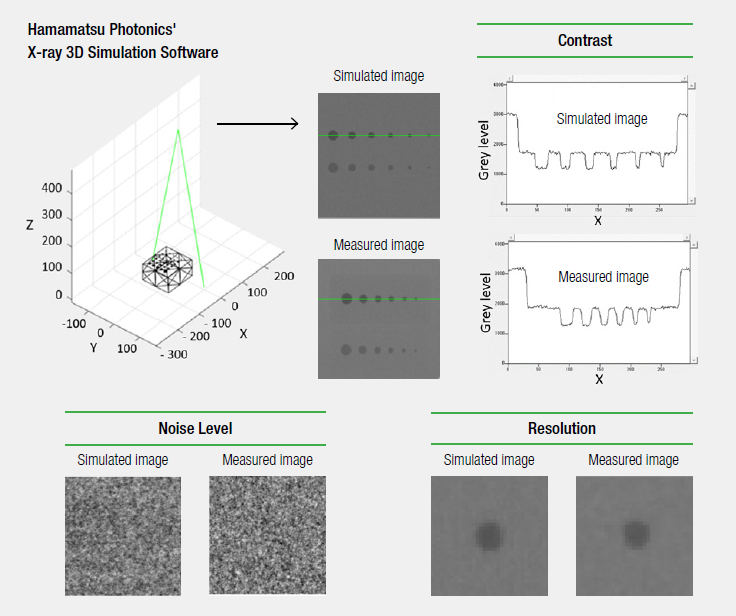

Simulating objects with unknown shapes or densities - like raw materials or packaged goods - can be difficult. To overcome this, test phantoms such as step charts with varying thickness are often used. The accuracy of simulations is confirmed by comparing simulated X-ray images against actual measured ones. Figure 2 shows an example of such a comparison. Parameters like contrast, noise level, and resolution from simulations are closely matched with real measurements to validate the simulation.

Hamamatsu’s X-ray simulations help customers select the best inspection parameters and support new camera development. Importantly, combining X-ray simulation with deep learning enables noise reduction without massive real image datasets, expanding its use to any object or inspection condition.

Figure 2. Example of X-ray image simulation of an acrylic block with Al spheres (virtual foreign object) and subsequent comparison with measured images. Details on the comparison between contrast, noise level, and resolution are shown. Image Credit: Hamamatsu Photonics Europe

De-noising via the Combination of X-ray Simulation and Deep Learning

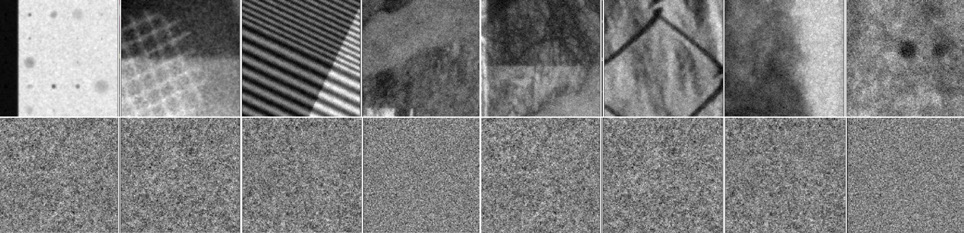

During the training phase of deep learning algorithms, conventional datasets - typically consisting of measured structures with added noise as inputs and the noise itself as the teacher data - can be replaced with simulated data. Using X-ray simulation software, it becomes possible to generate training images under a wide range of conditions, structural variations, and noise levels (see Figure 3).

Figure 3. Examples of simulated images obtained with the X-ray simulation software with different structures, X-ray conditions and noise levels. The corresponding simulated noise for each image is reported below. Image Credit: Hamamatsu Photonics Europe

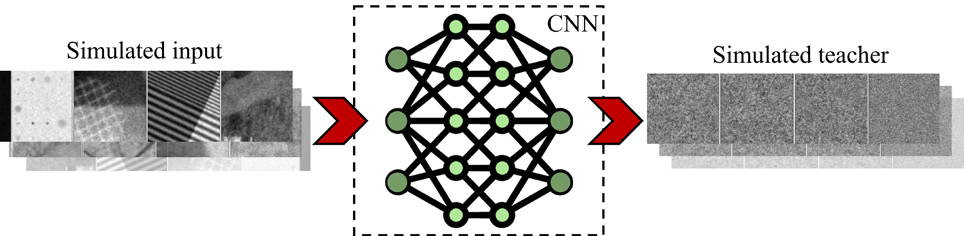

After training to recognize noise regardless of conditions, the neural network can extract noise from actual captured images. Figure 4 depicts this integration of X-ray simulations with CNN-based deep learning.

Figure 4. Combination of X-ray simulations and deep learning algorithms with CNN. Simulated images (structure + noise) are given as input to the neural networks, while simulated noise is used as a teacher image to train the algorithm. Image Credit: Hamamatsu Photonics Europe

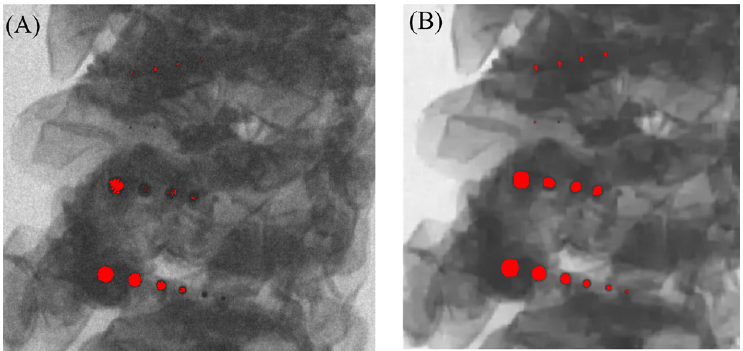

A key benefit of this approach is that it selectively removes only noise from real images while preserving structural information. This noise subtraction improves contaminant detection with simple thresholding methods. Figure 5 compares raw pork meat X-ray images without processing (5A) and after AI de-noising (5B), showing enhanced identification of foreign objects highlighted in red.

Figure 5. Comparison between raw (A) and AI de-noised (B) X-ray images of raw pork meat. By applying a simple threshold to the image grey levels, in the AI de-noised image better results are obtained in the identification of contaminants (red dots). Image Credit: Hamamatsu Photonics Europe

Finally, this simulation-enhanced AI de-noising solution supports real-time image processing for in-line inspection. Its initial release will target X-ray line scan cameras, with planned extensions to flat panel sensor compatibility.

References

- Hamamatsu Photonics. (2025). Food inspection | Hamamatsu Photonics. (online) Available at: https://www.hamamatsu.com/eu/en/applications/food-sorting-and-inspection/food-inspection.html.

- Hamamatsu Photonics. X-ray line scan camera | Hamamatsu Photonics. (online) Available at: https://www.hamamatsu.com/content/dam/hamamatsu-photonics/sites/documents/99_SALES_LIBRARY/sys/SFAS0035E_C14300s.pdf.

This information has been sourced, reviewed and adapted from materials provided by Hamamatsu Photonics Europe.

For more information on this source, please visit Hamamatsu Photonics Europe.