Sponsored by Gatan, Inc.Reviewed by Olivia FrostDec 3 2025

Forensic glass analysis plays a crucial role in criminal investigations, particularly in cases involving break-ins, car accidents, and violent crimes. The accurate determination of the elemental makeup of glass fragments can give critical evidence tying suspects to crime scenes.

The EDAX® Orbis™ II micro-XRF system provides a high-precision, non-destructive solution for elemental analysis, solving frequent issues in forensic applications.

Analytical Technique: Micro-XRF

Micro-XRF is a non-destructive analytical technique that enables the accurate elemental characterization of small sample areas.

In forensic glass analysis, peak intensity ratios of various elements are measured to assist in distinguishing between different glass sources. Ca/Mg, Ca/Ti, Ca/Fe, Sr/Zr, Fe/Zr, and Ca/K are among the most used elemental ratios.

These ratios have proven successful in distinguishing between different sources of soda-lime glass, allowing forensic professionals to connect shards to their origins with high confidence.

Challenges in Forensic Glass Analysis

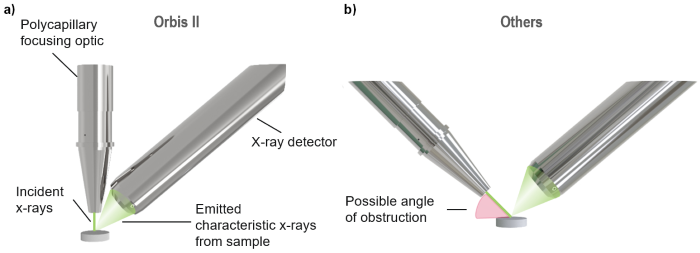

Traditional micro-XRF systems frequently have geometric restrictions due to slanted X-ray lenses (typically 45-50°), which can cause beam occlusion by nearby materials and misalignment problems due to sample height fluctuations or optical axis offset (Figure 1b).

These challenges are especially significant when studying small or irregularly shaped glass shards, as precise targeting is required to avoid misidentification.

Solution: Accurate Targeting with Orbis II

The Orbis II micro-XRF system overcomes these limitations with its innovative orbital turret, which allows for coaxial, perpendicular X-ray geometry. This novel design guarantees that the X-ray beam is perfectly aligned with the high magnification optical view, allowing for precise and reproducible targeting of the region of interest (Figure 1a).

Figure 1. a) The Orbis II geometry and b) a traditional systems’ geometry. Image Credit: Gatan, Inc.

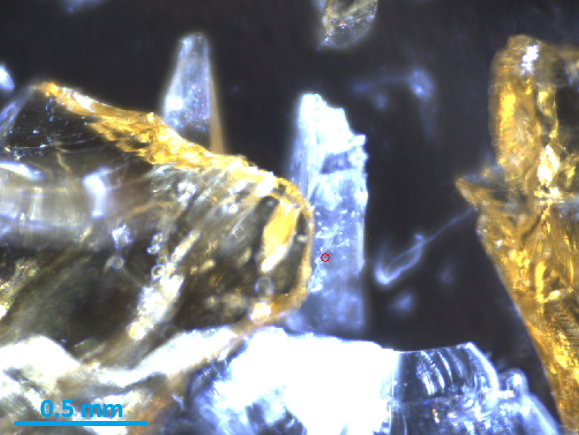

To show the forensic glass analysis method, a simulated sample of small and irregular glass shards from two different sources, clear and amber glass (Figure 2), was evaluated with Orbis II.

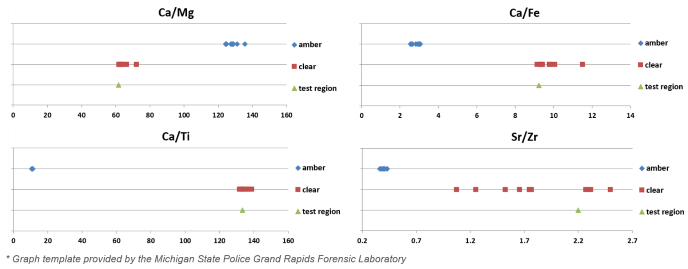

Ten measurements were taken from each glass type. The ensuing elemental intensity ratio graphs demonstrated a clear separation between the two sources. For each ratio, the data ranges for amber and clear glass did not overlap, indicating that the fragments were distinct and not from the same source (Figure 3).

Figure 2. Simulated sample consisting of clear and amber glass fragments. Image Credit: Gatan, Inc.

A key problem arose when a relatively large amber glass fragment obstructed the angled X-ray route to a test zone on a clear glass fragment (shown in red in Figure 2).

Due to this interference, traditional systems were likely to produce erroneous results. However, the perpendicular and coaxial shape of the Orbis II allowed it to successfully target the specified clear glass region. The resulting spectrum corresponded to the expected elemental profile of the clear glass.

This was confirmed by the elemental intensity ratio graphs (Figure 3), which showed that the test region's data consistently overlapped with the range of the clear glass but did not intersect with the range of the amber glass, indicating that the correct region was identified and analyzed without interference.

Figure 3. Peak intensity ratios of selected elements. Image Credit: Gatan, Inc.

Conclusion

The EDAX Orbis II micro-XRF equipment establishes a new standard for forensic glass examination. Its sophisticated optical alignment, precise targeting capabilities, and sturdy architecture reduce frequent sources of error, resulting in consistent and reproducible elemental data.

For forensic laboratories faced with evaluating complicated or minute glass samples, Orbis II provides the accuracy and confidence required for essential investigations.

Reference

- ASTM International. (2025). Standard Test Method for Forensic Comparison of Glass Using Micro X-ray Fluorescence (µ-XRF) Spectrometry. (online) Available at: https://store.astm.org/e2926-17.html.

This information has been sourced, reviewed and adapted from materials provided by Gatan, Inc.

For more information on this source, please visit Gatan, Inc.