In 2017, worldwide crude steel production was up by 5.3 % year on year, reaching a total of 1691 million tonnes.1

Much of this steel was produced using primary processes like electric arc furnaces and basic oxygen furnaces, and the same is true of production processes in 2025.

However, the need for more durable, refined steel with greater resistance to corrosion and heat has led to an increased use of vacuum degassing processes, such as VOD and RH, in secondary steel production.

These processes can attain extremely low levels of residual carbon while simultaneously retaining the desired levels of other alloys. To achieve the required standard for steel product quality, these processes require fast and continuous analysis of the furnace exhaust gas.

If the information regarding the composition of the gas leaving the furnace is inaccurate, variations in the decarburization process are only detected after the event, leading to the creation of out-of-specification steel.

Specialty Steel Production

Conventional steelmaking processes are well-suited to the production of standard-grade mild steels. But a further processing stage known as ‘secondary steelmaking’ is required to meet increasing demand for the high-quality, specialty steels needed in industries like construction, automotive, and aerospace.

Some of the processes for steel production currently available include adding alloys, stirring with inert gases such as argon, vacuum degassing, and powder injection. In fact, approximately 75 % of modern steel types have been developed over the past 20 years.

For example, contemporary cars are built with new steels that are both stronger and up to 35 % lighter than those steels used in the past.2

Blowing oxygen into molten steel in vacuum conditions saves time and money when compared to conventional steelmaking methods. This process also produces high-chrome steels with extremely low levels of residual hydrogen, nitrogen, and carbon, in turn yielding a wide range of stainless heat- and corrosion-resistant steels.

Stainless steel contains trace percentage levels of chromium. Since chromium is easily oxidized, it is important to decarburize stainless steel to a low carbon level while avoiding loss of chromium. This is achieved by decreasing the partial pressure of carbon monoxide, ensuring the preferential removal of carbon over chromium from the melt.

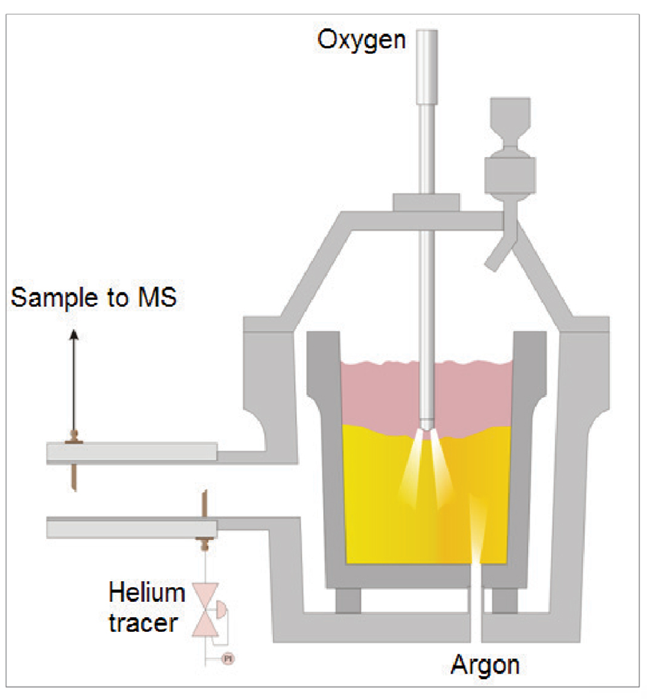

In practice, this is performed in Argon Oxygen Decarburization (AOD) furnaces by dilution with argon, or in Vacuum Oxygen Decarburization (VOD) or Ruhrstahl-Heraeus (RH) processes by reducing the pressure over the molten metal.

Figure 1 shows a typical VOD stainless steel production furnace.

Figure 1. Vacuum Oxygen Decarburization Furnace. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Dynamic Monitoring of Furnace Exhaust Gas

These varying specialty processes differ in various operational aspects, but they all need to produce a consistent quality of product that meets rigorous specifications, while also minimizing plant operating costs. Analyzing the composition of the furnace exhaust gas provides vital process information:

- CO and CO2: Decarburization rate, slag development, residual carbon content

- O2: Lance position, slag development, slopping prediction

- N2: Residual carbon, phosphorus, and manganese content, sloping prediction

- H2: Water content in flux additions, early detection of cooling leaks

If these results are to be used as part of a dynamic process control model, they need to be efficient, reliable, and accurate.

Advantages of Mass Spectrometry

Traditional Non-Dispersive Infrared (NDIR) analyzers are used in many conventional steelmaking processes to measure both CO (carbon monoxide) and CO2 (carbon dioxide), but when using these techniques, samples can only be taken at atmospheric pressure. In vacuum steelmaking, the melt process takes approximately 20 to 30 minutes, and in this time the pressure changes dramatically, generally from atmospheric pressure down to less than one mbar.

NDIR analyzers, therefore, must sample some distance downstream from the process. Analytical data is updated several minutes after the gas leaves the melt, and the control system must operate on historic rather than real-time data.

Paramagnetic analyzers can be used to measure O2 (oxygen), while thermal conductivity analyzers can be used to measure H2 (hydrogen). These analyzers are also hampered by slow responses, while the operation of three different types of analyzers burdens the plant maintenance.

In addition, these analyzers cannot evaluate inert gases, so N2 (nitrogen) is calculated by difference, a result that can suffer from any errors made in the previous three analytical techniques.

Mass spectrometry is suitable for monitoring vacuum processes since it operates at high vacuum. It is able to adeptly monitor the seven components in Table 1 in just seconds rather than minutes, ensuring that the plant control model is updated regularly with precise compositional data.

Key Control Parameters

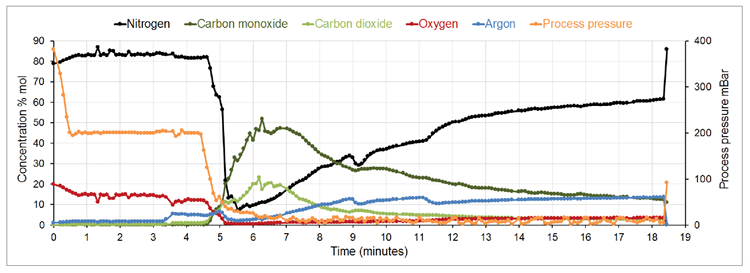

Figure 2 gives an example of VOD process data. The rapid changes in composition are evident, indicating the benefits of fast analysis provided by the MS. Process pressure is also shown, dropping from 380 to five millibars during the melting process.

Figure 2. Trend display of typical VOD process data. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Precision of Analysis

At the core of the Thermo Scientific™ Prima PRO Mass Spectrometer (MS) is a magnetic sector analyzer, which offers unparalleled precision and accuracy when compared to other mass spectrometers.

Though Thermo Fisher Scientific manufactures both quadrupole and magnetic sector mass spectrometers, over thirty years of industrial experience have proven that the magnetic-sector-based analyzer offers superior performance for industrial on-line gas analysis.

Notable advantages of magnetic sector analyzers include improved accuracy, precision, long intervals between calibrations, and resistance to contamination.

Typically, analytical precision using a magnetic sector analyzer is two to 10 times better than a quadrupole analyzer, depending on the complexity of the mixture, and the gases analyzed.

A unique feature of the Prima PRO magnet is that it is laminated. Its analysis times are comparable to a quadrupole analyzer, meaning it offers a unique blend of high stability and rapid analysis.

This allows the fast and secure analysis of an unlimited number of user-defined gases. The scanning magnetic component is controlled with 24-bit precision using a magnetic flux measuring device for especially stable mass alignment.

The ion source is an enclosed type for high sensitivity, maximum contamination resistance, and minimum background interference. This is a high-energy (1000 eV) analyzer that offers rugged performance in the presence of vapors and gases that could potentially contaminate the analyzer.

Model performance specifications for the Prima PRO MS are demonstrated in Table 1. Analytical performance is demonstrated by analyzing the calibration bottle over a one-hour period following calibration, with an analysis time of only six seconds. The standard deviations measured on the calibration cylinder will be equal to or better than the stated values.

Table 1. Typical Prima PRO MS performance for VOD and RH processes. Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

| Gas |

Typical concentration range % mol |

Calibration cylinder concentration % mol |

Standard deviation % mol |

| H2 |

0-15 |

2 |

≤ 0.002 |

| CO |

0-90 |

40 |

≤ 0.03 |

| N2 |

0-100 |

10 |

≤ 0.03 |

| O2 |

0-25 |

1 |

≤ 0.002 |

| Ar |

0-50 |

41 |

≤ 0.03 |

| CO2 |

0-70 |

5 |

≤ 0.01 |

| He |

0-10 |

1 |

≤ 0.002 |

Prima PRO Variable Pressure Inlet

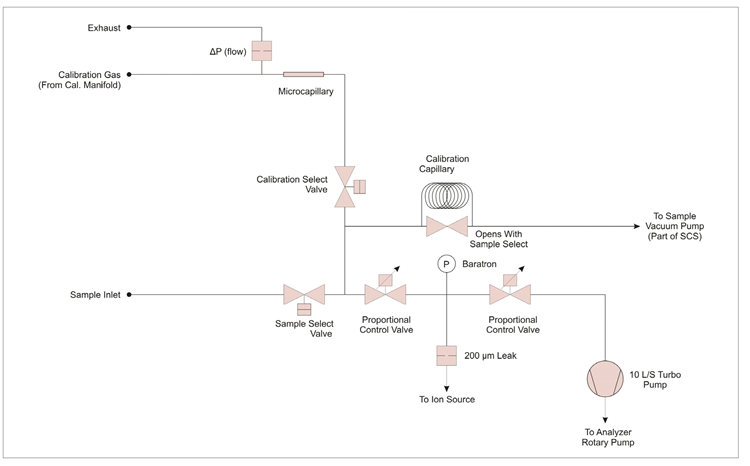

In principle, a mass spectrometer is ideal for monitoring vacuum processes, since the MS analyzer itself is operating at high vacuum. However, the pressure in the MS must remain constant as the process pressure changes.

The unique VP inlet of the Prima PRO MS contains two control valves working in opposition: as one valve opens, the other closes. This ensures a wide, dynamic range and fast, precise control. The inlet controls the analyzer pressure at just 0.1 mbar and can therefore handle sample pressures down to 0.3 mbar. The VP inlet is shown in schematic form in Figure 3.

Figure 3. Schematic of Prima PRO VP variable pressure inlet. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Gas Sampling System

Getting a reliable, representative gas sample from the vacuum process to the Prima PRO MS is especially crucial to ensure that the MS provides accurate and reliable data to the plant control system. Thermo Fisher collaborated with the experienced system integrator Thyson Technology Ltd. to develop a sample system specifically designed for VOD/RH gas sampling.

This sampling system is the result of many years of experience with the application. It consists of three major components: the control system, the sample conditioning system panel, and a pair of heated sampling probes. The first two units are mounted on a single floor-standing frame, which is connected directly to the Prima PRO MS, and the sample probes are mounted on the process duct.

Due to the high level of dust loading in the process, the heated sampling probes each have a built-in filter, which is automatically cleaned by the system. It carries out a quick pre-clean before every run, removing any dust that may have gathered on the probes since their last use.

Once the pre-clean is complete, it signals to the Prima PRO system that a good sample is available and the unit is sampling the VOD/RH process gas, at which point the MS starts analyzing. At the end of each run it carries out a complete cleaning process, back purging the sample system filter, sample lines, and probes with nitrogen in sequence. Figure 4 shows the Prima PRO MS and the Thyson Technology sample conditioning system.

Figure 4. Prima PRO with VP variable pressure inlet and Thyson Technology sampling system. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Using MS Data to Control the Process

The unique combination of precise inlet pressure control, magnetic sector stability, and quantitative software helps to ensure that the process data produced by the Prima PRO MS is reliable and precise. A variety of industry-standard communication protocols can transfer this data to process control systems, optimizing the steelmaking process.

Analysis of Trace Helium to Improve Decarburization Control

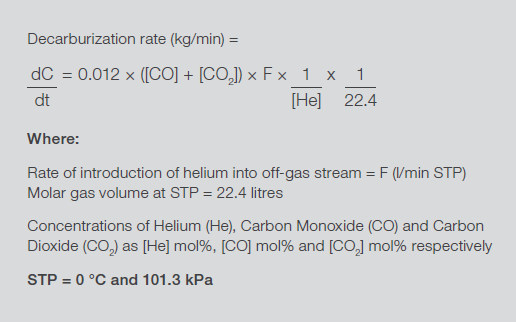

As well as measuring the six standard gases, the Prima PRO MS can accurately analyze helium at ppm levels. This is introduced as a tracer gas at a known flow rate. By combining this with the concentration values of carbon monoxide and carbon dioxide, the Prima PRO MS provides a highly reliable means for calculating the decarburization rate.

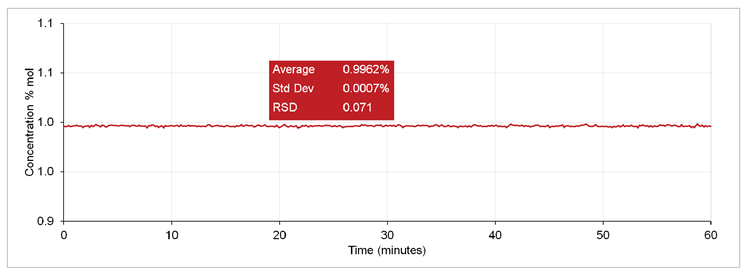

This is constantly updated with the high-speed data gained from the MS. Table 2 shows how GasWorks software’s Derived Value function can calculate decarburization rate using a metered helium introduction, and Figure 5 shows the Prima PRO MS system’s stability, measuring helium at a 1 % concentration over one hour.

Table 2. Derived Value calculation for decarburization rate using metered helium introduction. Source: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Figure 5. One hour stability plot for helium trace gas (1 % concentration). Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Improving Hit Ratio

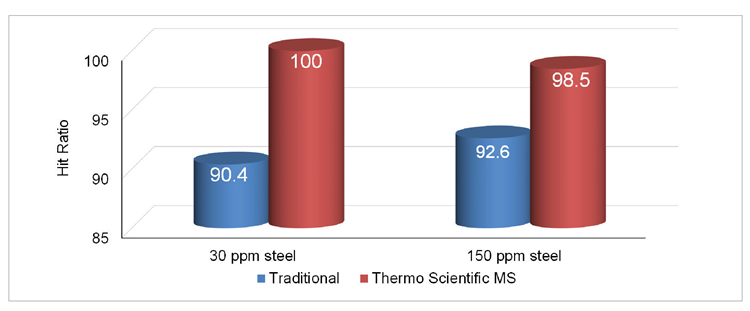

The Prima PRO system allows the precise control of the carbon content of molten steel. Figure 6 shows the improvement in hit ratio of the carbon content in two grades of steel, using Thermo Scientific™ process MS compared with traditional gas analysis methods. For steel with 30 ppm carbon content, the hit ratio increased from 90.4 % to 100 % without over-blowing.

Figure 6. Improved hit ratio for low carbon steel with Thermo Scientific process MS. Image Credit: Thermo Fisher Scientific – Environmental and Process Monitoring Instruments

Summary

The Thermo Scientific™ Prima PRO Process Mass Spectrometer offers optimal on-line measurement stability and precision for vacuum degassing process monitoring and control. Its fault-tolerant design, combined with extended intervals between maintenance and simplified maintenance procedures, helps to ensure maximum availability.

Prima PRO benefits

- Greater yields and steel quality produced

- Lower ownership cost

- Direct on-line analysis over the complete pressure range, from 1000 mbar to 0.3 mbar

- Monitors all gases – N2, O2, CO, CO2, H2, Ar, He

- Uninterrupted high-speed monitoring, enabling more accurate kinetic model performance

- Fast payback of installation costs – a 1 % increase in throughput is worth around $20,000 a day for a furnace producing 10,000 tons of steel daily, meaning the costs of installing a Prima PRO system can often be paid off in less than 30 days

References:

- World Steel In Figures 2017, World Steel Association

- World Steel Association Media Centre, "About Steel"

This information has been sourced, reviewed, and adapted from materials provided by Thermo Fisher Scientific – Environmental and Process Monitoring Instruments.

For more information on this source, please visit Thermo Fisher Scientific – Environmental and Process Monitoring Instruments.