Feb 16 2001

Image Credit: Olga Save/Shutterstock.com

Article updated on 12/02/2020 by Gaea Miranda

For many applications, such as buildings requiring large spans of glass, toughened glass is the only acceptable alternative. This type of glass has exceptional strength compared to standard annealed (stress-free) float glasses.

The Mechanism Behind Toughened Glass

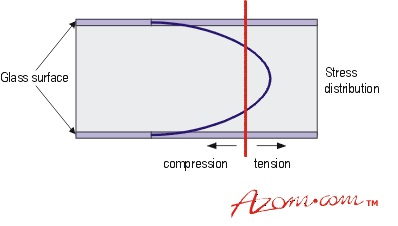

The improved properties of toughened glass come as a result of the stress profile that is induced in the material by the toughening heat treatment process. When performed correctly, the glass surface is in compression, whereas the center is in tension. In toughened glass, the applied tensile load must overcome the compressive stress at the surface before the surface can go into tension and fail.

Figure 1. Schematic representation of the stress profile in toughened glass

The heat treatment process involves heating annealed glass up to a temperature between its glass transition temperature and its softening point; after this, the surface shall be rapidly cooled. Usually evident among air jets, this process freezes the surface, while the interior may still be molten. Consequently, there is a temperature differential across the thickness of the glass. The hotter core section contracts at a faster rate as compared to the outside until an isothermal state is reached.

Initially, the rapid cooling of the surface tends to induce tensile stress in the surface. This is reversed in the latter stages of cooling and ultimately results in compressive stresses on the surface.

Key Properties of Toughened Glass

Toughened glass features some relevant properties that make it a material of choice among various industries:

- Superior strength compared to annealed glass

- When failure occurs, glass panels shatter into small pieces, rather than sharp shards, which is the case with annealed glass.

- Good chemical resistance

- Attacked by hydrofluoric acid (HF)

Applications of Toughened Glass

Toughened glass can be applied in a variety of industries, including the transport industry and building and construction.

Transport Industry

Within the transport industry, toughened glass can be found in various forms ranging from cars to boats and ships. In all cases, there are regulations that specify which properties must be in place, such as strength, thickness and light transmission.

Building and Construction Industry

Toughened glass finds many applications in the building industry from the internal to external aspects. Internally, toughened glass may be used in frameless shower screens and office partitions, while externally, it can be used for large window spans and balustrading.

Toughened glass panels can be manufactured to almost any shape, with the limiting factor often being specific furnace dimensions at both ends of the scale. The glass can also be machined, with holes, beveled edges, and shaped into other forms. However, all machining must be carried out prior to toughening. Furthermore, all edges must be polished, as unpolished edges may act as sites for crack propagation during the heat treatment process.