The global trade in counterfeit goods continues to increase at an alarming rate, with a report published by the Organization for Economic Cooperation and Development (OECD) and the European Union Intellectual Property Office (EUIPO) in 2019 highlighting that international trade in counterfeit and pirated products could have accounted for $509 billion USD in 2016 (approximately 3.3% of world trade).

What is most notable about these figures is that they are based solely on global customs seizures, and therefore do not factor in the unknowable amount of counterfeit goods that were either not seized or that were produced and consumed domestically.

This data alone highlights the vital need for an easily applicable, reliable, and affordable means of combating counterfeiting.

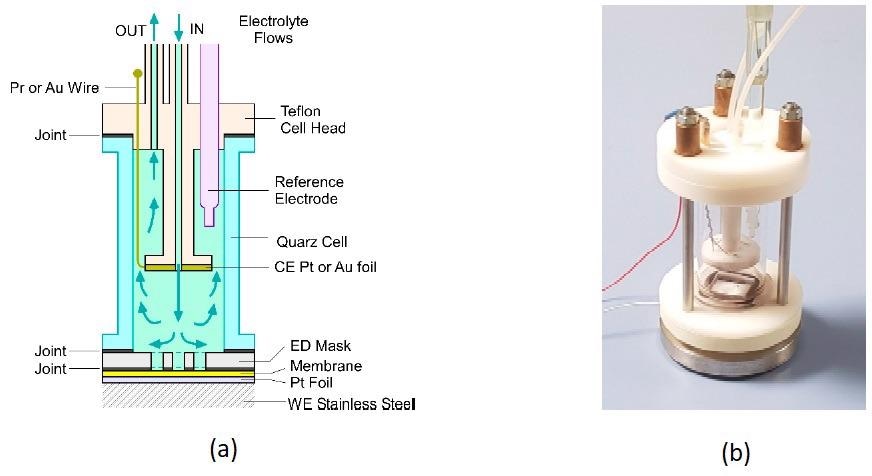

Figure 1. Presentation of the ED cell: (a) descriptive scheme of its working principle; (b) picture of the ED cell, the overall height of the mechanical structure is about 17 cm.

Companies such as OEM manufacturers or pharmaceuticals producers tend to work with vast numbers of industrial and commercial products, with the health and safety risks associated with counterfeit parts or even medicines potentially threatening the lives of consumers.

Existing solutions to ensure product authenticity and traceability typically include verifiable logos, certificates of authenticity, barcodes and QR codes, or RFID chips. More robust security strategies frequently involve the use of microstructures such as holograms or iridescent areas that can be verified via optical reading.

Counterfeiters are increasingly innovative and resourceful, however, and all of these methods have the potential to be compromised or bypassed.

The use of invisible optical techniques offers increased safety because these are only searchable using specific techniques such as laser or UV light, and it is necessary to know the location and configuration of these micro- or nano-scale ‘secret’ markings in order to verify the product is authentic.

These covert laser readable (CLR) surface structures return specific speckle images when read, revealing the physical structure of the surface at even nanometer scales.

The most notable downside to these CLR structures is that they must be produced via costly lithographic techniques, making them unsuitable for the industrial or commercial-scale production of large amounts of products; for example, those common to the OEM or pharmaceutical industries.

In order to offer a viable anti-counterfeiting option for these sectors, CLR-based techniques are required to have marginal production cost implications, be straightforward and affordable to detect and verify, and must be possible to easily adjust any CLR markings to enable precise coding of specific parts, batches or products.

New research presented in the special ‘Polymer Nanocomposites with Different Types of Nanofillers and Advanced Properties for Several Applications’ issue of the Applied Nano journal detailed a feasibility study of a promising solution to meet these CLR requirements using self-organized nanostructured CLR (n-CLR) flexible tags with adjustable parameters.

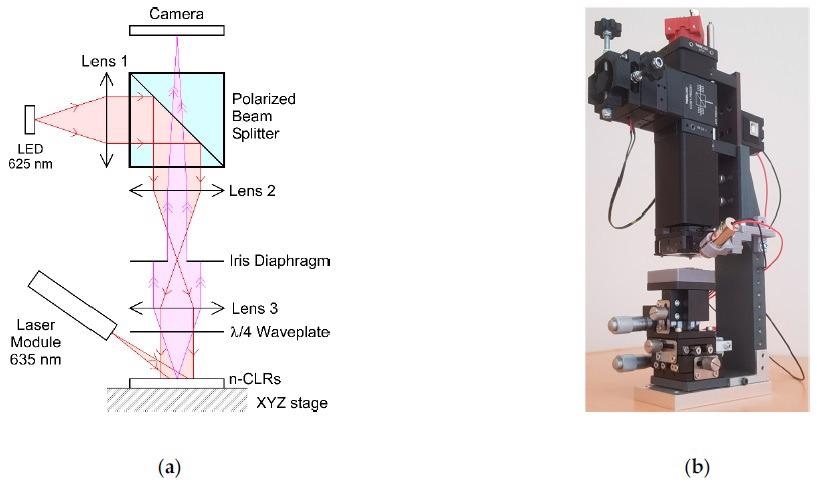

(a) Working principle of the optical setup for speckle images acquisition. Red beams indicate lights shining the n-CLR, the pink beam indicates the light emitted by the n-CLR surface and captured by the camera. Either the LED or the laser module are used as light source. All optical components are fixed, except the distance between the n-CLR and the lens 3 which can be adjusted to focus the image on the camera. (b) Picture of the optical setup. Its overall height is about 30 cm. Image Credit: Gravier, L. et al., Applied Nano

These n-CLRs are fabricated using widely-recognized, well-respected template synthesis nanotechnology to shape a polymer thin film.

This production process significantly reduces the number of steps required to produce these devices by making use of production methods already popular in the printed circuit board (PCB) industry.

A gold layer of approximately 50 nm is sputtered on one side of a polymer membrane via physical vapor deposition (PVD). Shadow masks can also be used if necessary. Next, the pores are filled using a template synthesis technique involving an electrochemical deposition (ED) of a conventional nickel electrolyte solution into the pores. Using ED masks allows this process to be completed in a single step, making it ideal for large-scale production.

In terms of reading the nano-scale patterns, a simple technique is used that effectively lights up the n-CLRs using LED or laser beams in order to capture diffraction images that highlight the position and depth of the speckles present.

There remains a need for further work to refine and develop this process and its related technology, but its potential is already evident. The authors state that they are currently working on formalizing the identification of n-CLR surfaces and employing machine learning approaches to define correlation parameters that will allow existing image processing algorithms to process, identify and verify these n-CLR surfaces.

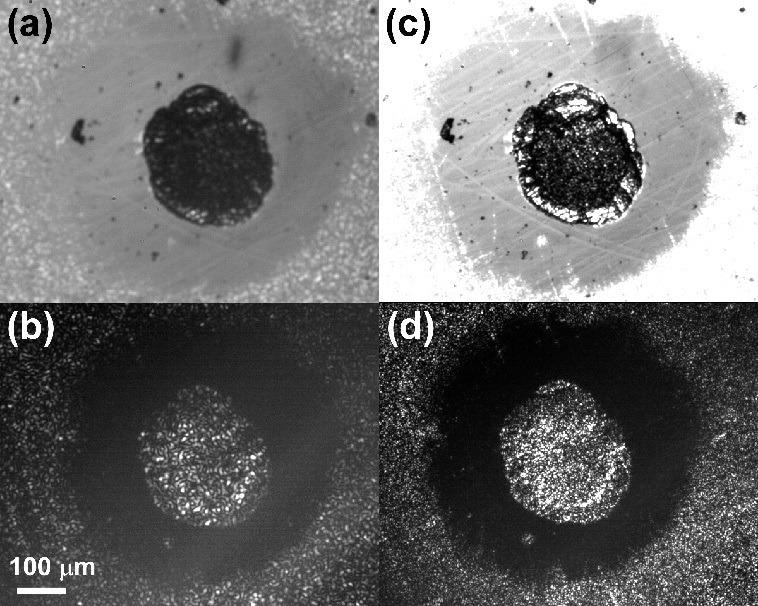

Representative speckle images of one n-CLR (Membrane A, VED = −1.20 V). Light source: LED (a,c) and laser (b,d). Iris diphragm opening: 0.8 mm (a,b) and 3.5 mm (c,d). Image Credit: Gravier, L. et al., Applied Nano

The issue of globalized counterfeiting operations continues to place considerable strain on customs and industry while potentially placing consumer safety at risk. A widely applicable, ultra-robust, efficient, and cost-effective means of assuring utmost traceability and authenticity of key consumer goods, OEM products, and vital pharmaceuticals is needed urgently, perhaps now more than ever.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.