The world's high energy demand is primarily based on the production and consumption of fossil fuels. This has resulted in severe environmental consequences that include pollution, climate change, and the high emission of greenhouse gases (GHG).

While different renewable energy sources can fulfill the energy demands, they rely on climatic conditions that are difficult to control and unpredictable. In comparison, biomass is considered one of the prospective solutions to resolve the challenges developed by renewable energy and fossil fuels.

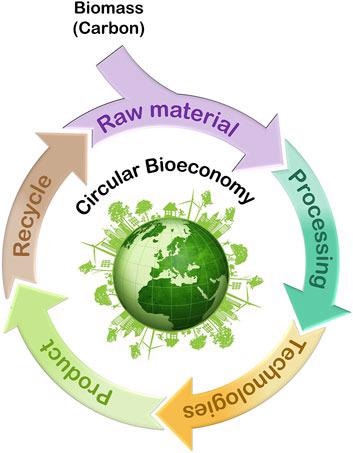

In the fossil-based economy (FBE), fossil fuels fulfill the majority of the energy demands, whereas in the circular bioeconomy (CBE), the majority of the energy demands are fulfilled by biomass. The main advantage of CBE is that it is a sustainable approach and reduces the environmental issues caused by FBE.

The conversion of FBE into a CBE is aided by biomass as a feedstock to produce valuable chemicals and biofuels. CBE requires the development of efficient resource strategies and sustainable green technologies, and its main aim is to support the value of a product and reduce waste, GHG emissions, and ecosystem damage. CBE is based on procedures that are the foundation of a carbon-zero society and primarily comprises biomass carbon, with economic, social, and environmental factors as key drivers.

In the present study, the researchers have presented various strategies to convert biomass in biofuels and bioenergy within the CBE framework.

CBE Frameworks and Strategies

The first step of CBE development is to match the international supply and demand of energy using biomass production, sustainable process developments, and reutilization strategies. It must be noted that sustainable process development must include detailed life cycle analysis and techno-economic studies. Additionally, the CBE economy must also be focused on greenhouse gas repurposing strategies and bioenergy production using biofuel.

Agricultural wastes are considered a challenge that causes environmental issues in the traditional FBE. A study included by the researchers proposed using coconut juice residues as a feedstock to make bacterial cellulose, which could further be acetylated to make bio-cellulose acetate membranes.

These membranes could additionally be used to remove CO2 from biogas produced by the anaerobic digestion of biowaste, which will finally produce renewable biomethane. The produced CO2 could be used for processes such as syngas production, chemical separation, and microalgae cultivation which is essential for CBE.

Use of biomass within the circular bioeconomy concept.

Furthermore, it will also lead to developing a value chain that is expected to improve the CBE. Overall, the agricultural residues could be used to make high-value products for biogas purification in energy production, resulting in a zero-waste environment.

A common practice used for reducing agricultural waste is crop residue burning, but this procedure is the root cause of air pollution, GHG emission, and radiation imbalance. Moreover, it also causes significant health risks and is responsible for declining organic matter in the soil. Another study referred by the researchers aims to shift crop residue management (CRM) from traditional methods to a CBE framework.

This shift will ensure the long-term viability of the agroecosystem. Additionally, the CRM bioeconomy is built on four pillars: smart agriculture practices, waste bioeconomy, stakeholder capacity building, and proactive government policy. Furthermore, the proposed bioeconomy crop residue management approach will contribute to sustainable development by providing substitutes to minimize crop residue burning and improve farmers' livelihoods.

Another strategy to develop CBE is to use lipase for biodiesel production. Several studies have demonstrated that lipase can be selectively catalyzed to convert bio-oils to biodiesel. However, the production of lipase-based biodiesel is heavily dependent on the ability of enzymes to be reused multiple times without significant loss of activity. One method to overcome the limitation is immobilization through adsorption-crosslinking to improve lipase reusability.

This process will reduce the dependency on the FBE and support shifting towards the CBE, as diesel and petrol production are the primary drivers of FBE.

Conclusions

To conclude, it is critical to adapt CBE frameworks at the earliest to meet future food, animal feed, and energy requirements. The main bottlenecks in developing CBE concepts are resources, information, and research. Furthermore, additional knowledge is required to fulfill bioenergy, biomass, and biofuels supply and demand. In addition to this, social participation is also essential to improve the CBE strategies and frameworks. It is also critical that the governments proactively develop policies to strengthen the CBE frameworks and research.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Caetano Nídia S., Xu Suyun, Banu Jeyakumar Rajesh, Sani Rajesh K., Karthikeyan Obulisamy Parthiba, Editorial: Biomass, Bioenergy, and Biofuels for Circular Bioeconomy, Frontiers in Energy Research, V10,2022, https://www.frontiersin.org/article/10.3389/fenrg.2022.851047