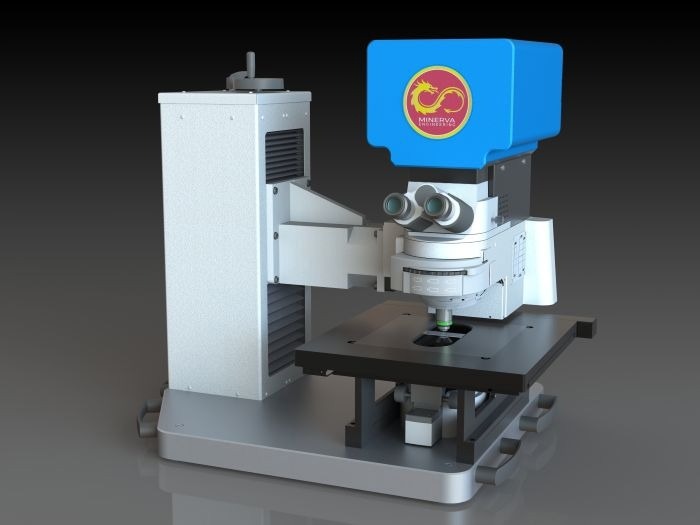

Minerva Engineering Introduces the Cobalt Dragon™ Microspectrophotometer for Advanced Flat Panel Display Development.

Image Credit: Minerva Engineering, Ltd.

Image Credit: Minerva Engineering, Ltd.

Minerva Engineering, the leading innovator in UV-visible-NIR microspectroscopy solutions, proudly announces the release of the Cobalt Dragon™ Microspectrophotometer, a large-format spectroscopic and imaging system engineered for the analysis and development of flat panel displays and other large-scale optical devices.

The Cobalt Dragon™ combines the proven optical precision of Minerva’s microspectrophotometers with an extended sample stage and advanced automation, enabling spectral and imaging measurements of microscopic regions across large display substrates. Designed for both research and production environments, the system measures transmittance, reflectance, fluorescence, and polarization spectra—from the deep ultraviolet to the near infrared—while also providing high-resolution imaging and film thickness mapping.

"The Cobalt Dragon™ was specifically developed to meet the needs of the display industry, where large-format panels must be characterized with microscopic precision," said Dr. Jumi Lee, President of Minerva Engineering. "From OLED and microLED displays to AR and VR components, this instrument allows engineers and scientists to analyze optical performance at the pixel level while maintaining full-stage accessibility for large samples. It’s the perfect fusion of high-accuracy microspectroscopy and scalable engineering."

The Cobalt Dragon™ Microspectrophotometer supports both manual and fully automated operation, with precision motorized stages for mapping and pattern analysis across full display substrates. Integrated with Minerva’s advanced Lambdafire™ software, the system offers powerful tools for data acquisition, spectral comparison, and film thickness measurement—critical for evaluating color uniformity, layer consistency, and optical coating performance in display development.