Industrial applications need lighter, stronger, safer and cleaner materials on a daily basis. Additionally, new techniques like additive manufacturing require the development of new metal powders, as well as allowing for the design of parts – this is something that isn’t possible with other techniques. Because of this, many applications make use of composite materials for lighter, stronger parts. Energy materials are also developed and used for cleaner power production and optimized storage.

As technology advances, new tomography and microscopy techniques enable researchers, scientists and engineers to create digital models that can be used for the characterization of materials. Whether for better characterization of existing manufactured or natural materials, or even the development of new ones, the Thermo Scientific™ Avizo™ Software allows for comprehensive understanding of their performance, properties and structure.

A reliable, fully automatable solution for both industrial and research-based applications, the Avizo™ Software provides optimized workflows for the efficient characterization of materials, regardless of the modality used to acquire digital data.

It also provides simulation modules and advanced image processing tools among a range of other features, all designed to allow users to speed up the innovation process, produce more reliable and better performing materials while reducing time to market.

Ceramics, Glasses and Porous Media

Effective characterization of porous materials very much depends on the size, shape and distribution of pores, and possibly the channels that connect them. Other materials such as glass or ceramic rely on an understanding of the different particle types when estimating the performance of the material. When characterizing materials, some of the key parameters that must be examined are permeability, porosity and tortuosity.

Avizo™ has been specifically developed with these requirements in mind, and the software provides an advanced workflow for the analysis of particles and the characterization of pore networks. These analyses and characterizations also include quantification of particles or pores in the material, an examination of their volume distribution, distance and shape, and also, computations of the material’s physical properties such as the aforementioned permeability, porosity and tortuosity.

Data courtesy of Visible Cement Dataset

Data courtesy of Shimadzu Corporation (inspeXio SMX-225CT FPD HR) Courtesy of Zellwerk GmbH

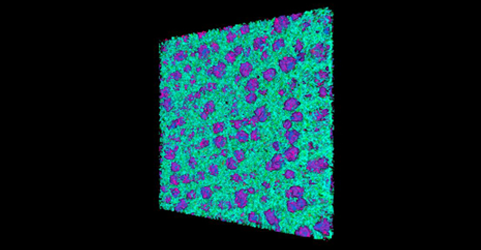

Metals, Alloys, and Powders

Lighter, stronger and more durable metals are essential in machinery, transportation, energy production, building materials and consumer products. As well as these metals, newer manufacturing techniques like additive manufacturing mean that new types of metal powders must also be developed.

Avizo™ Software allows users to gain an in depth understanding of the structure-property relationship in metals or alloys. Not only can its advanced quantification capabilities be used for the measurement of the quality of metal powders in additive manufacturing applications, but, the size, sphericity and coating of each grain of powder can be measured. All these factors allow the user to determine the quality of the powder itself.

Composites, Polymers and Fibrous Materials

A wide range of applications rely on the use of fibrous materials. As a result of this, being able to understand the mechanical properties of the material is an essential part of the manufacturing process. It is also important to be able to detect imperfections or defects during this process, as these can negatively affect the design cycle of a new part or the control of the manufacturing process itself. Not only this, but analysis of deformation of the material under physical constraints can allow for damage prediction, for example, the prediction of voids induced in fibers during deformation.

The Avizo™ Software platform is able to offer an advanced workflow, ideal for the quantification of fibers including providing their length, orientation and diameter. It also allows for the detection of defects, such as changes of density or voids in the matrix, that may have resulted from the manufacturing process.

Batteries

As the search for alternative sources of energy continues, this in turn implies new discoveries in material science, as well as new developments in the fields of catalysts, batteries and solar cells. For example, Solid Oxide Fuel Cells (SOFCs) are lauded as one of the most promising electrochemical devices, with the potential to efficiently co-generate electricity and heat of fuel gases.

Estimation of the permeability and tortuosity of the porous phase of the electrode can be achieved with Avizo™ Software. Because of this, the electrochemical performance simulation can be enhanced with effective transport parameters, while the quantification of phase distribution, triple phase boundary (TPB) and connectivity assists in effective characterization of the cell’s performance.

Biomaterials

Recent developments in the manufacturing and characterization of biomaterials have led to ground-breaking progress in the areas of scaffold techniques and tissue engineering.

Avizo™ Software is ideal in these settings as it can be used efficiently characterize extremely porous media while at the same time quantifying pore distribution, size and the interconnectivity of the porous network. Using this data, it is then possible to determine key considerations like effective surface for cell attachment and mechanical strength.

Additionally, it is possible to use Avizo™ Software to validate experiments. Users can achieve this by generating Finite Element Analysis models then collaborating these with FEA solvers, as well as by performing deformation analysis from a material sample that has been subjected to physical constraints.

Semiconductors

Designers and manufacturers of semiconductor devices must regularly push the boundaries of physics. Defect detection, failure analysis, materials characterization and process evaluation are essential factors when considering the successful commercialization of new electronic devices.

Avizo™ Software excels in this area, with its image processing and 3D visualization tools allowing for quick detection of defects; for example the detection of voids in the solder balls of a Ball Grid Array (BGA).

Courtesy of nanoX Technology Pte Ltd

Food and Agriculture

A number of 3D imaging techniques can be used to provide insights into food’s structure, particularly exploring how this changes in various situations such as processing operations. These techniques can include scanning electron microscopy (SEM), X-ray micro-computed tomography (microCT) and magnetic resonance imaging (MRI).

Avizo™ Software comes complete with a comprehensive food and seeds analysis toolset, making it quick and easy to perform microstructural characterization. This enables a better understanding of the relationship between microstructure and the properties needed in food engineering, microbiology, chemistry and safety.

Data courtesy of Nikon Metrology

The Solution of Choice for Materials Science

Avizo™ is the solution of choice for a range of materials science applications and settings. As a versatile, advanced application it can be used to explore and comprehend the structures and properties of a range of materials.

With tools ranging from standard visualization and measurement right through to quantification, advanced image processing, analysis and reporting; the Avizo™ Software is able to provide a comprehensive, multimodality digital lab that excels in advanced 2D and 3D materials characterization.