Sponsored by ProtoAug 27 2020

For most people, computed tomography (CT) scanning is a familiar medical term for a diagnostic x-ray test. However, the uses of CT scanning extend well past the medical field. CT x-ray scans are also performed to allow visualization of the internal features of structures within many solid materials, including their shapes, sizes, and textures.

A single x-ray photograph is often taken to see into an object, with the resulting image being an average of the density of the material – a 3D object flattened into 2D. However, CT scanning involves a series of x-ray photographs being taken rotationally around an object, which can then be used to generate a 3D image.

Conventional CT typically scans large areas, so the resolution is limited to about 1 millimeter due to limitations in the number of pixels on the x-ray detector; however, by scanning a smaller area, micro-CT scanners can provide a much higher resolution – about 1000 times higher (1 micron). This level of detail is often needed to image small, complex structures, allowing researchers to make important discoveries in a variety of fields.

Given the important and diverse applications of micro-CT, there has been a big push for researchers to develop improved equipment with which to image samples. Proto recently partnered with KA Imaging, a spin-off from the University of Waterloo, to develop the inCiTe micro-CT scanner, which takes images continuously while x-rays impinge upon a rotating sample.

This system is the first commercial CT scanner to feature KA Imaging’s unique, high-spatial-resolution amorphous-selenium (a-Se) detector. The compact benchtop design makes it possible to perform micro-CT scans without extensive space requirements. In addition, the a-Se detector has an 8-micron pixel size, which is much smaller than typical Si-based flat panels. This detector allows for direct conversion of x-ray photons into electrical charges. This direct conversion coupled with a high detective quantum efficiency (DQE) enables efficient imaging at low flux and high energy, making the inCiTe a very versatile machine.

Because of the detector’s small pixel size, this system has the added advantage of phase-contrast imaging, which allows for the investigation of materials that cannot be visualized with conventional x-ray imaging. For example, soft biological tissues and polymers typically have poor absorption; however, when an x-ray passes through these materials, it is also refracted.

Refraction occurs when an x-ray wave interacts with matter and is slowed down. Since the frequency of a wave always stays the same, the wavelength must decrease, and thus a phase shift (shift in wave peak positions) occurs relative to the original wave before it entered the medium. After leaving the object, the refracted (phase-shifted) x-rays can start to interfere with each other, and when given a long enough propagation distance, the interference effects can be observed on an x-ray detector.

The effect of phase-contrast imaging is most pronounced when there is an abrupt change in refractive indexes, such as found at boundaries and edges within a material. Phase shift effects are typically 100 to 1000 times stronger than effects from absorption, thereby improving the visibility of samples that typically have weak x-ray absorption. However, the interference effects occur over very small distances, so a high-resolution detector is needed in order to observe this edge enhancement.

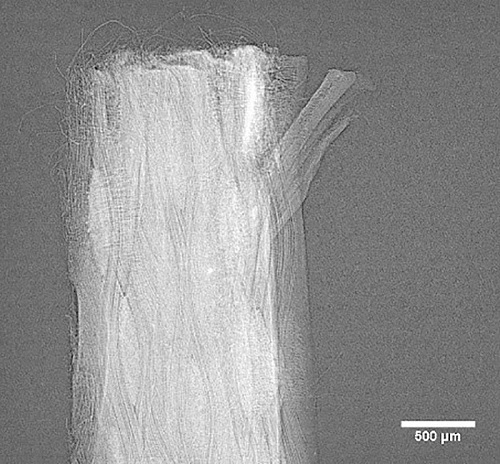

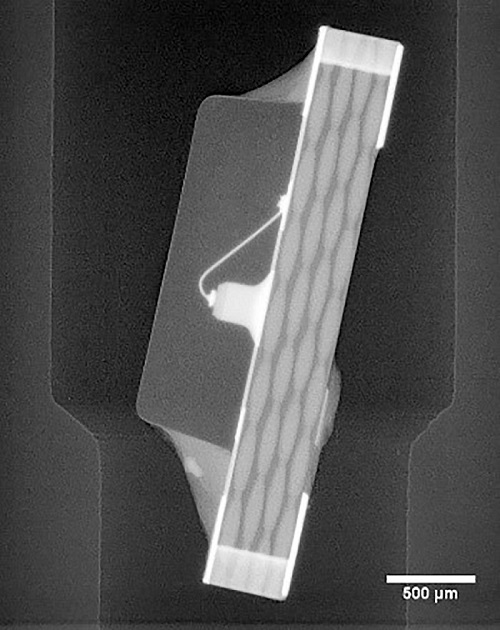

Using the inCiTe system, tissues can be visualized with high contrast, such as in the mouse knee shown below (Figure 1), enabling the cartilage to be examined in great detail. The composite material pictured below (Figure 2) is a piece of Kevlar. With the help of phase-contrast imaging, individual fibers sized 10-20 μm can be seen within the material. The third CT image below (Figure 3) is an LED. Phase-contrast capabilities allowed its substrate layers to be identified, and the wire bond shapes can be seen clearly thanks to the system’s high-resolution detector.

Figure 1. High-contrast image of cartilage in a mouse knee

Figure 2. Individual fibers of Kevlar

Figure 3. Substrate layers of an LED

The inCiTe system is ideal for analyzing fine structures in materials such as polymer composites and biomaterials but can be used in various fields and applications, including non-destructive testing (NDT), electronics, additive manufacturing, geology, and agriculture.

This information has been sourced, reviewed and adapted from materials provided by Proto.

For more information on this source, please visit Proto.