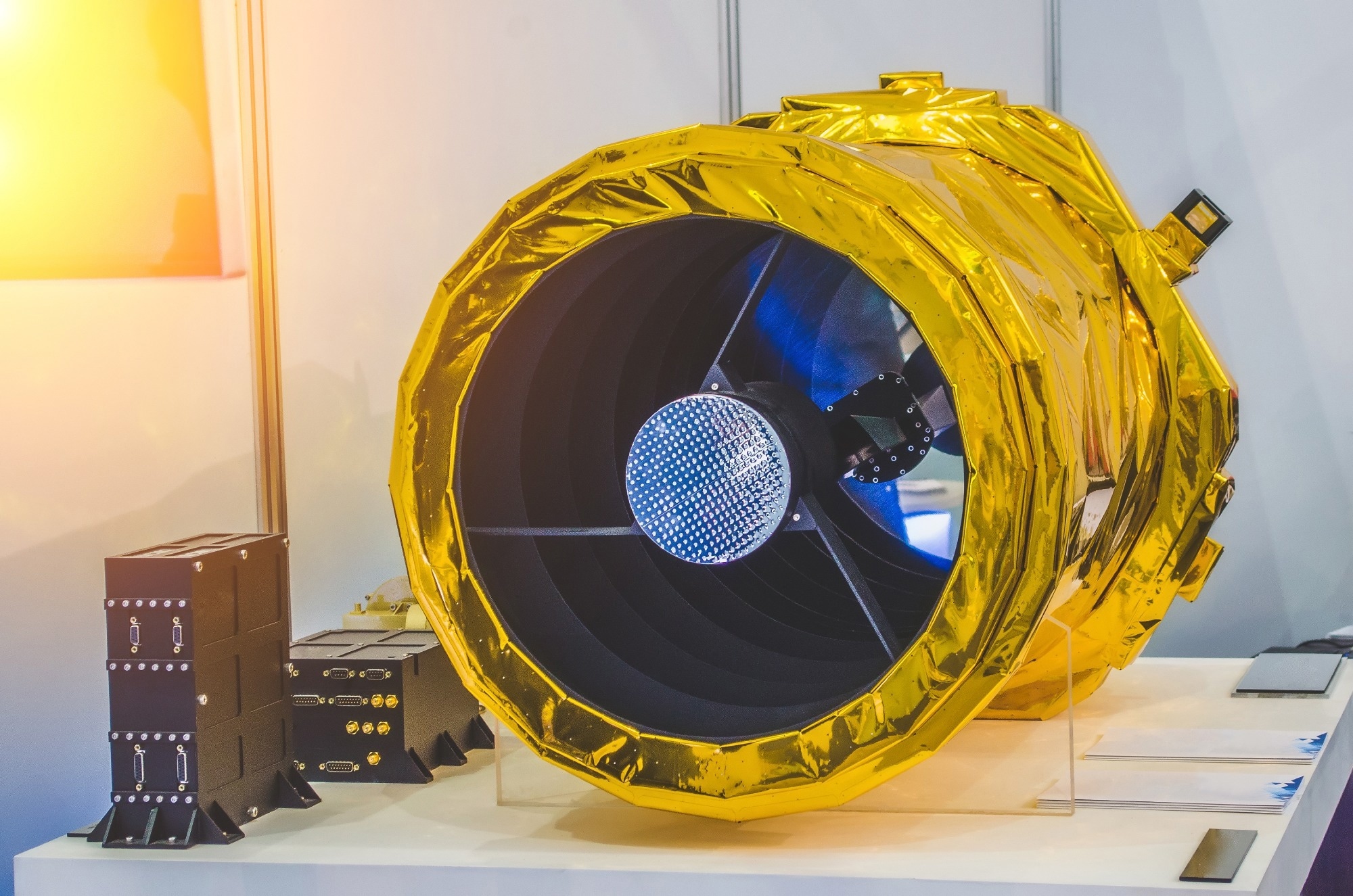

Have you ever seen photographs of space probes, satellites, or space stations that appear to be coated in gold foil? If so, did you know that the golden color of this blanket is due to the highly engineered polyimides used in its construction rather than the precious metal it resembles?

The blanket material, more accurately known as multilayer insulation (MLI), is wrapped around portions of satellites and spacecraft in orbit that require protection from solar and electromagnetic radiation in space.

It also inhibits heat loss from the inhabited areas of spacecraft. Due to the restricted air convection in a spacecraft's microgravity, radiation is the predominant mechanism of heat transmission in and out of space.

The use of MLI is critical for the continuous operation of sensitive equipment as well as the safety of astronauts aboard.

Figure 1. Multilayer insulation (MLI) based on aluminized polyimide films. Image Credit: aapsky/Shutterstock.com

MLI's polyimide film substrate can endure temperatures from -260 °C to 400 °C, with short-term exposures exceeding 480 °C. It has low outgassing, making it appropriate for usage in space, and is resistant to degradation from ultraviolet radiation.

As a result, the lightweight MLI serves as an ideal insulation material for space applications. A properly built MLI also serves as the spacecraft's first line of defense against dust impacts in space.

MLI, or multilayer insulation, is typically made by applying a thin layer of metal—usually aluminum—onto a durable polyimide film through vapor deposition. While the finished MLI remains relatively thin overall, it consists of multiple even thinner layers stacked together, which is where the term "multilayer" comes from.

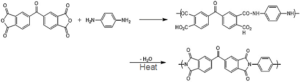

The polyimide film used to make the MLI is made by reacting a dianhydride with a diamine in two steps (Figure 2), resulting in a polymer with high heat and chemical resistance.

Polyimides have glass transition temperatures that range from 300 °C to 400 °C or greater. They also have an extremely high tolerance for heat or thermo-oxidative damage.

Figure 2. The two-step process for making thin polyimide films using a dianhydride and a diamine. Image Credit: Jayhawk Fine Chemicals Corporation

Polyimides with different performance characteristics can be tailored by choosing specific combinations of diamines and dianhydrides.

For applications requiring high-temperature resistance, commonly used dianhydrides include benzophenone tetracarboxylic dianhydride (BTDA), pyromellitic dianhydride (PMDA), and biphenyl tetracarboxylic dianhydride (BPDA).

So, the next time you see photos of spacecraft with that iconic gold-colored coating, you can thank these remarkable molecules—dianhydrides—for playing a key role in creating MLI, an essential component for thermal control in space environments.

Acknowledgments

Produced from materials provided by Vinay Mishra, PhD, Technical Director, Thermoset Additives, Jayhawk Fine Chemicals Corporation.

Reference

- Noaa.gov. (2016). As Good As Gold: Are Satellites Covered in Gold Foil? | NOAA National Environmental Satellite, Data, and Information Service (NESDIS). [online] Available at: https://www.nesdis.noaa.gov/content/good-gold-are-satellites-covered-gold-foil.

For more information on this source, please visit Jayhawk Fine Chemicals Corporation.