Inductively coupled plasma (ICP) sources were first developed decades ago, with regular use in the semiconductor industry at a time when plasma sources primarily deposited silicon oxide and silicon nitride.

Today’s materials are more demanding, particularly in plasma-assisted atomic layer deposition. Older sources face challenges relating to oxygen contamination from sputtered dielectric windows, usually alumina or quartz.

Separately, using a high-density power source generated in a small-area tube before diluting the activated species over a larger deposition area is also considered an outdated approach by some.

Small area sources are used to minimize the backflow of metal-organics into the dielectric tube, as this deposition has the potential to block RF transmission to the plasma gas, potentially damaging the dielectric liner.

Free from oxygen contamination problems, the new hollow cathode plasma source is able to accommodate both metallic and insulating deposition on the cathode.

Without these issues, a high-density plasma source can now be created to match substrate dimensions, meaning there is no longer any need to dilute the plasma species over a larger area. This approach also allows the plasma source to be brought closer in.

The OkyayTechP100 uses Meaglow’s large-area high-density hollow cathode source and features its own sample entry port and ellipsometer ports. The instrument’s new large area source can achieve a high electron density of 1013 cm-3 over the entire deposition area.

The table below features results from the University of Connecticut, highlighting the benefits of moving away from the traditional ICP plasma delivery method.

Source: “Real-time in situ ellipsometric monitoring of aluminum nitride film growth via hollow cathode plasma-assisted atomic layer deposition” A. Mohammad et. al. J. Vac. Sci. Technol. A 37 (2019) 020927

|

Fiji® with ICP |

Fiji® with

hollow cathode |

OkyayTechALD®

Large area

hollow cathode |

| Film density at 200 °C deposition |

2.6 g/cm3 |

2.8 g/cm3 |

> 3.0 g/cm3 |

| Al:N ratio (by XPS) for optimized conditions |

1.34 |

1.13 |

1.0 |

| Plasma exposure to achieve saturation |

> 40 seconds

at 300 W |

> 40 seconds

at 300 W |

20 seconds

at 100 W |

Optimized GPC at

200 °C |

0.6 Å

at 300 W |

0.96 Å

at 300 W |

1.1 Å

at 100 W |

Plasma Source and Reactor Options

OkyayTechP100 reactor with Meaglow’s latest hollow cathode design features the strongest 300 W plasma source and compact reactor available for ALD.

A plasma source has been developed to convert OkyayTech’s thermal ALD systems. This model has been designed to accommodate 4″ wafers and features a separate sample loading port. No cooling water is required, and its operation is not impacted by deposits on the cathode.

Electron density is measured in the presence of nitrogen gas, revealing a result of greater than 1013 cm-3 at 300 watts of RF power, around an order of magnitude higher than other commonly available 300 W products.

It is also important to note that plasma density is generated over an area equal to that of the substrate, unlike other solutions that generate high-density plasma in a small volume before dispersing it to a larger area.

The compact reactor OkyayTechP100 is supplied with the Meaglow source, ensuring exceptionally high plasma density across the entire substrate area. The instrument’s design has already been implemented in 4″, 8″, and 12” systems with significant success.

Okyay Enerji adds, “We’re developing plasma sources and reactors specifically for ALD, not trying to adapt old legacy sources that are less than optimum for the technique.”

Image Credit: OkyayTech ALD

Improving Film Quality with New Hollow Cathode Plasma Source Designs

A paper published by the University of Connecticut and its collaborators (J. Vac. Sci. and Technol. A 37 (2019) 020927) outlined its achievement of good quality, highly stoichiometric AlN using hollow cathode plasma-assisted atomic layer deposition (HCPA-ALD).

Film densities were near bulk values, and the source’s high radical flux required significantly lower RF power to achieve this improvement in material quality compared to previous efforts. At these lower powers, shorter plasma cycles were also possible: 20 seconds at 100 watts versus 40 seconds at 300 watts.

A team at the University of Texas at Dallas was able to achieve similar improvements in silicon nitride deposition, with a hollow cathode plasma source enabling excellent quality, highly stoichiometric, high-density PA-ALD grown material (IEEE Electron Device Letters 39 (2018) 1195).

Many members of the ALD Research Community use Meaglow’s hollow cathode plasma sources as replacements for inductively coupled plasma (ICP) sources due to the reduced risk of oxygen contamination when depositing non-oxide materials.

However, the papers by the University of Connecticut and the University of Texas at Dallas highlight even more important findings for industry.

For example, relatively low plasma damage at an extremely high radical flux, so high that the ion signal (ion densities are similar to ICP sources) is swamped by the signal of radicals during optical emission spectroscopy measurements.

These results imply reduced deposition times, potentially enabling more stoichiometric, higher quality material.

Image Credit: OkyayTech ALD

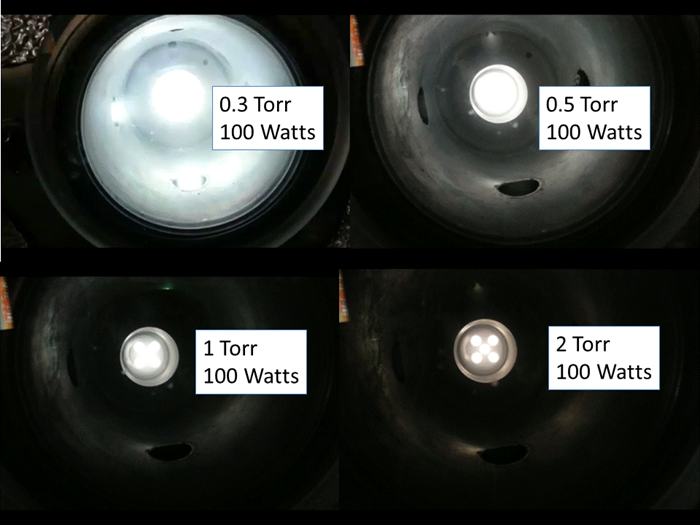

Hollow Cathode Plasma Sources’ Operating Range

Image Credit: OkyayTech ALD

A recent review paper, J. Vac. Sci. Technol. A 37 (2019) 030902, on plasma ALD has inaccurately reported that hollow cathode plasma sources can only accommodate a very narrow operating range of 0.3 to 2 Torr.

However, none of the references cited provides a pressure range, so it is possible that this was due to a misconception of the authors or a lack of experience with hollow cathode plasma sources.

All of Okyay Enerji’s designs feature larger pressure ranges than those provided in the review; however, recent advances have extended operation down to tens of milliTorr and potentially even lower.

The operating pressure range of the company’s earliest hollow cathode design is provided in the Japanese Journal of Applied Physics 51 (2012) 01AF02.

Used for chemical vapor deposition work, the optimum pressure for that cathode was one Torr, but measurements shown in this study clearly illustrated an operating range of at least 0.23 to 6.6 Torr or broader, even for that early design.

Lower optimum pressure ranges are required when designing for ALD systems, so designs have been optimized for operation between 0.3 and 1 Torr for such applications since around 2014.

The full operating range of the company’s barrel design plasma sources, such as its series 50 source, has a lower limit of around 100 mTorr and an upper limit of > 5 Torr. These sources are typically used as an ICP replacement.

The image below features one of these sources at 120 mTorr with nitrogen at 100 watts of RF power.

The company’s newer designs, based on large-area hollow cathode plasma sources, are able to accommodate even lower pressures. These have been run to the base pressure of Okyay Enerji’s test systems, reaching as low as 35 mTorr.

Image Credit: OkyayTech ALD

Acknowledgments

Produced from materials originally authored by Okyay Enerji Ar Ge Mühendislik Ticaret ve Sanayi Ltd. Sti.

Each trademark belongs to its respective owner.

This information has been sourced, reviewed, and adapted from materials provided by OkyayTech ALD.

For more information on this source, please visit OkyayTech ALD.