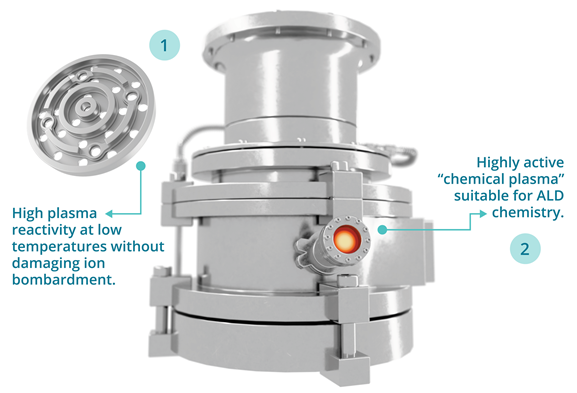

OkyayTech Layerava® features a compact reactor design with a large plasma source.

Image Credit: OkyayTech ALD

Choose Layerava® HCPE-ALD

Layerava® Hollow Cathode Plasma Enhanced Atomic Layer Deposition

- No oxygen contamination

- No plasma damage

- Faster growth rate

- Better crystal quality

- Reduce complexity

Process Performance and Film Quality

- Pure films

- Device reliability

- Lower deposition time

- Electrical improvement

System Design and Complexity

Get in touch now

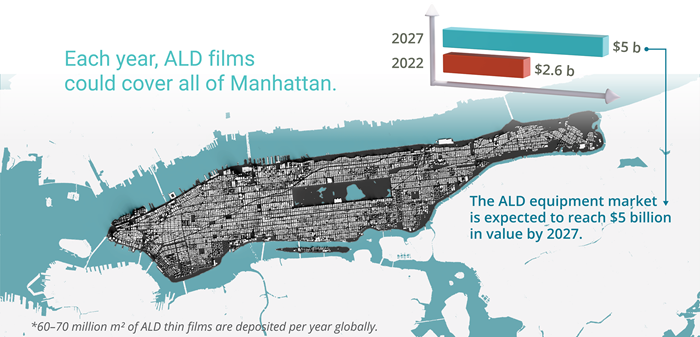

Market and Technology

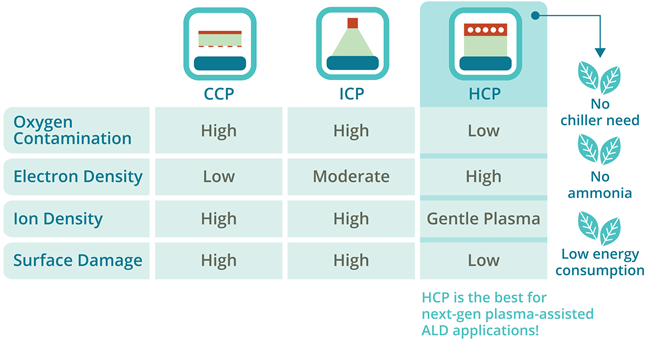

Common plasma sources, such as CCP and ICP, were created decades ago for use in the semiconductor industry. At that time, plasma sources were primarily used to deposit silicon oxide and silicon nitride. Today, novel materials face increasingly stringent demands in the expanding industry, particularly for plasma-assisted atomic layer deposition (ALD).

Image Credit: OkyayTech ALD

Traditional plasma-assisted ALD approaches have drawbacks such as oxygen contamination, plasma damage, and complicated system requirements. Hollow cathode plasma-assisted ALD is the most promising prospect for addressing those issues in a single system.

Image Credit: OkyayTech ALD