The palm oil industry is among the most productive vegetable oil producers worldwide, supported in part by the oil palm’s exceptionally high yield (kg/ha/yr) compared with other vegetable oil plants. However, further improvements in production can be achieved by determining oil content at multiple stages throughout the process, from the fields to the mills.

Benchtop Time Domain Nuclear Magnetic Resonance (TD-NMR) is a well-established method that has been successfully adopted and used for decades to determine oil content in food and agricultural products.

TD-NMR measurements offer several advantages over conventional approaches: they are non-destructive, rapid, reproducible, and solvent-free. Like near-infrared (NIR) spectroscopy, TD-NMR is often calibrated to align with oil and water content results generated by solvent extraction and oven drying, for which there are established ISO methods.1,2

Nevertheless, unlike NIR, TD-NMR enables the configuration of a primary calibration using the oil of interest, as the signal is directly and linearly related to hydrogen content. This capability has been applied to snack foods and fish products.3,4

TD-NMR provides multiple advantages over NIR and conventional extraction techniques, including:

- Capability to measure total oil content in the samples, not just from the surface, making it suitable for large, inhomogeneous samples

- Unaffected by factors such as color and particle size

- Linear calibration can be achieved with as few as three reference samples, depending on the reference method accuracy. Alternatively, calibration may be performed against refined oil extracted from seeds, nuts, or fruits.

Image Credit: Hesty drg /Shutterstock.com

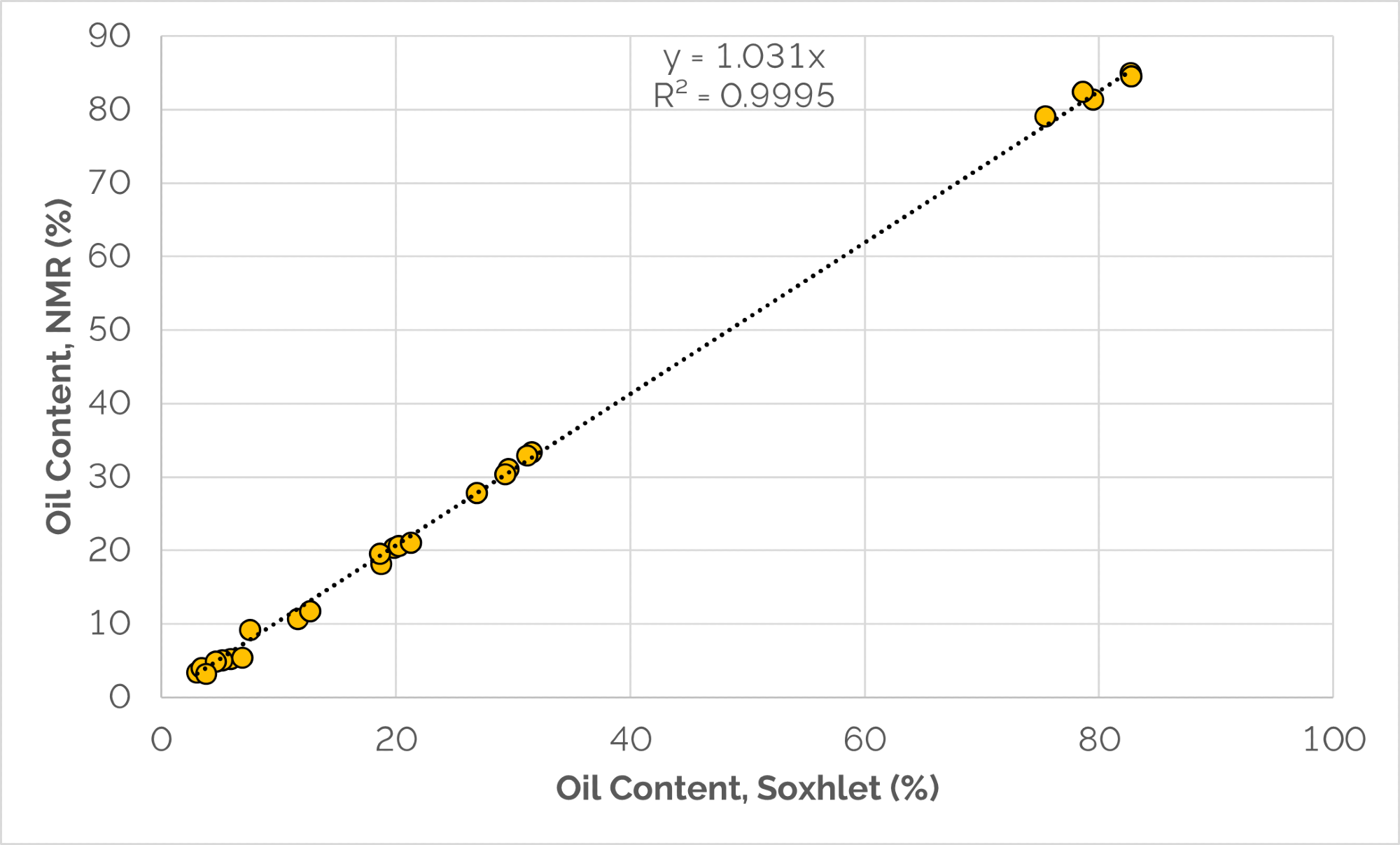

Figure 1 illustrates a strong correlation between TD-NMR results calibrated using 100 % palm oil, and Soxhlet extraction across a broad concentration range. This demonstrates that TD-NMR can determine the oil content not only in dried palm fruit (mesocarp), but also in residues from crushing and extraction, using just a single calibration. Consequently, TD-NMR can be used, as a tool for maximizing oil yield while minimizing processing losses.

Figure 1. Comparison of NMR and Soxhlet results for palm fruit and the residues during various stages of processing. Image Credit: Oxford Instruments

As a result, benchtop NMR offers numerous potential applications across the palm oil industry, as discussed further below.

Measuring Oil in Palm Mesocarp for Bunch Analysis

Determining oil content in palm mesocarp is primarily important to plant breeders seeking to measure oil yield from their crops through bunch analysis. Traditionally, oil content is measured using Soxhlet extraction following oven drying, limiting sample throughput.

While the mesocarp must be dry before NMR analysis, the sample throughput is much higher than Soxhlet, which is constrained by analysis time and the number of samples able to be analyzed at any given time. Moreover, NMR has demonstrated accuracy equivalent to the hexane extraction method while eliminating the need for solvents, other chemicals, fume cabinets, and costly disposal processes.5,6

The technique is straightforward: after weighing in a vial, samples are conditioned at 50 °C for 20 minutes to ensure that all oil is melted before analysis. Measurement lasts only 16 seconds, making the time per sample short when measured within a large sample batch. The instrument can be calibrated against, and consequently, can obtain results equivalent to those of the reference extraction method.

Alternatively, a primary calibration can be obtained using crude palm oil to determine total oil content. While extraction methods have not always been shown to remove total oil content, TD-NMR is capable of measuring the total oil present in the dry tissue, including oil remaining after Soxhlet extraction.

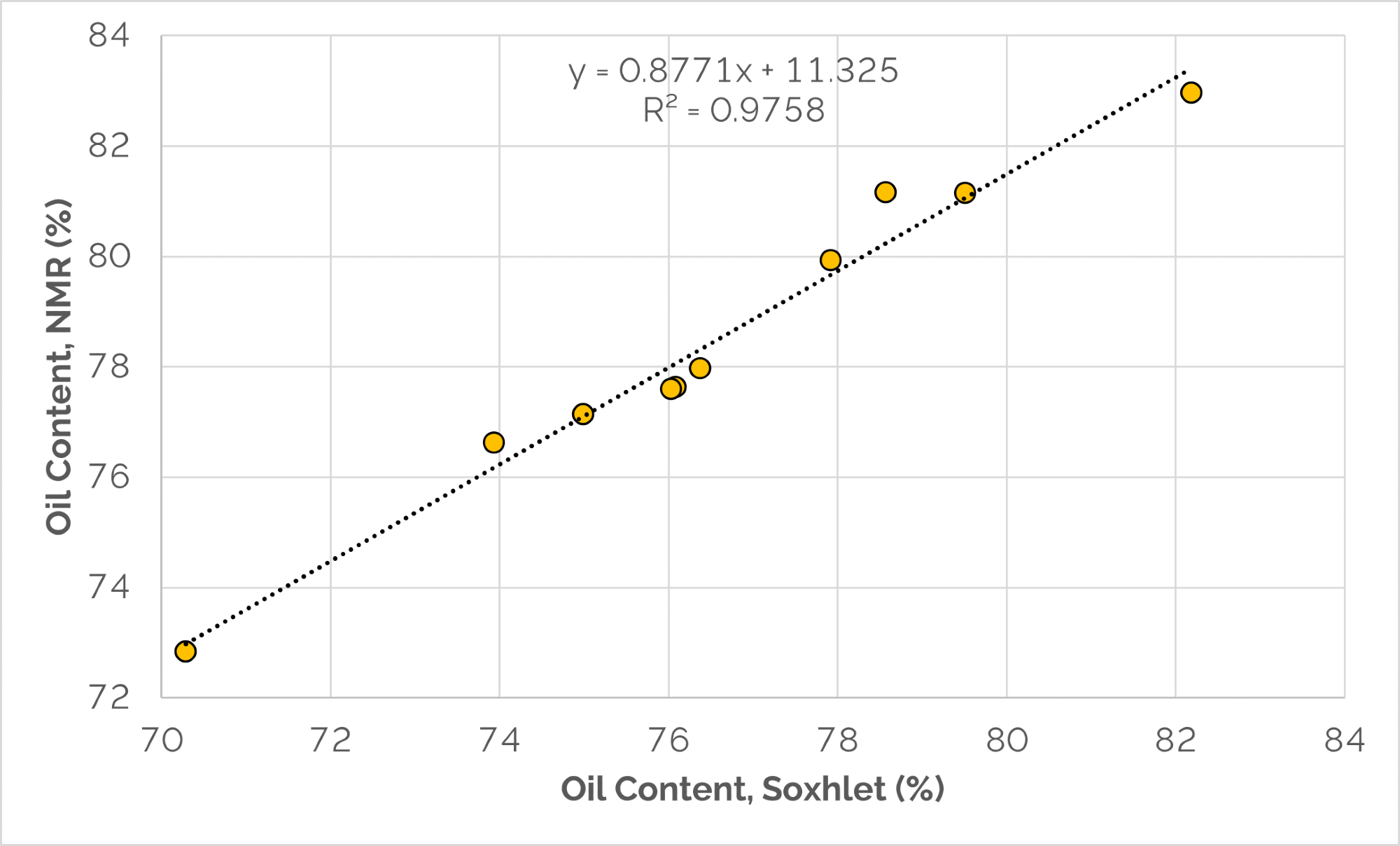

A comparison between Soxhlet extraction results and an NMR oil calibration for dried palm mesocarp is presented in Figure 2.

Figure 2. Comparison of TD-NMR vs. Soxhlet extraction results for dried palm mesocarp shows offset and scatter due to oil not extracted by Soxhlet. Image Credit: Oxford Instruments

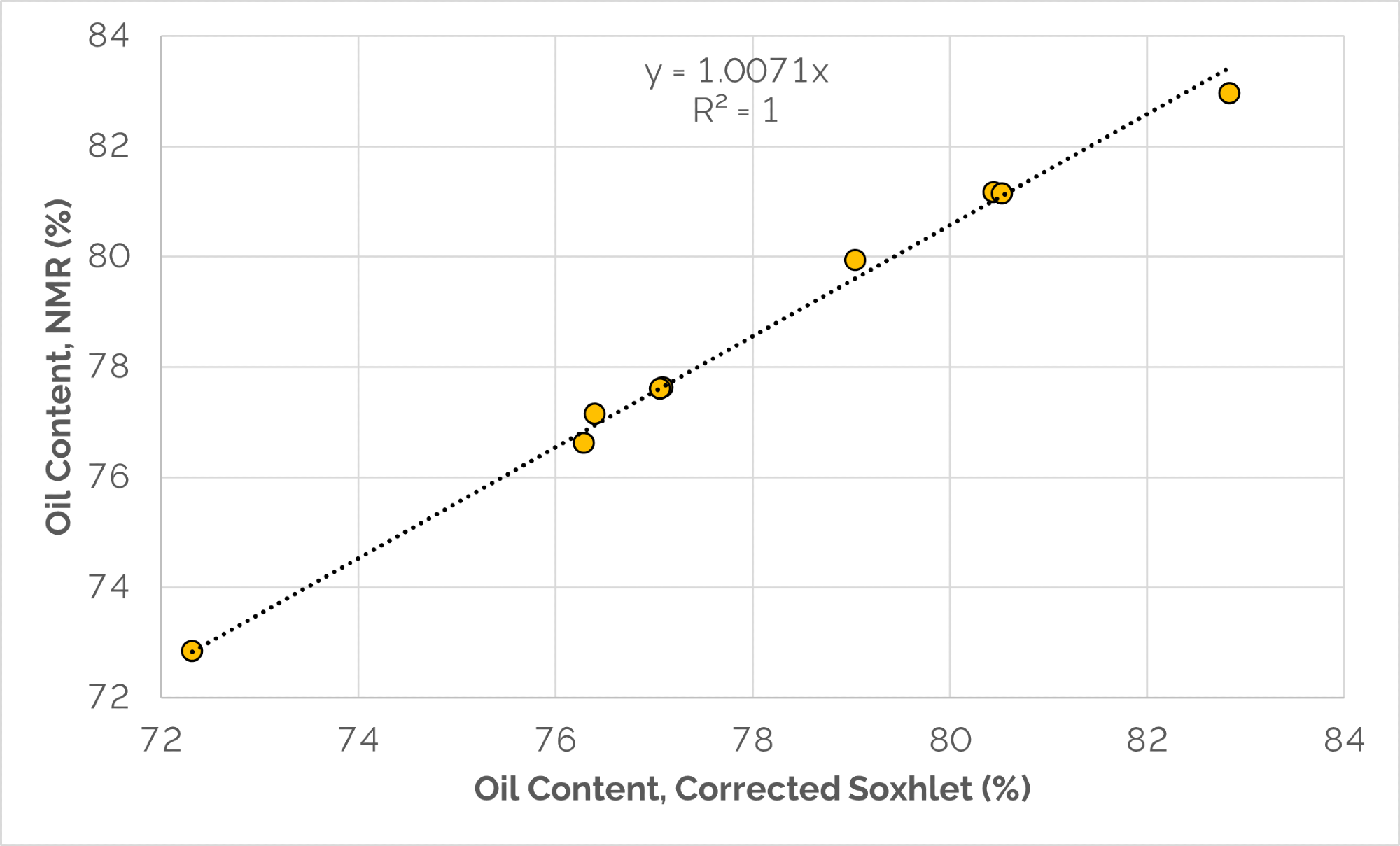

Typically, NMR results are higher than Soxhlet values because NMR quantifies total oil content, whereas Soxhlet does not measure the unextracted oil. The latter is not constant and can contribute to data scatter. Since this scatter cannot be corrected through a calibration bias, the unextracted oil content in the Soxhlet residue was measured by NMR, and a correction was applied to each Soxhlet result (Figure 3).

Figure 3. Results from TD-NMR vs. Soxhlet for dried palm mesocarp corrected for unextractable oil show direct 1:1 correlation and reduced scatter. Image Credit: Oxford Instruments

The most noticeable feature is the reduced scatter, reflected by enhanced correlation (R2). The NMR and corrected Soxhlet data now show a direct correspondence, meaning the line passes through the origin.

These findings further demonstrate that NMR not only accurately measures oil content in residues, facilitating optimization of crushing and extraction processes, but also determines total oil content in oil-producing crop samples.

Measuring Oil in Pressed Palm Fibre

Measuring the oil content of pressed palm fibre in mills is important for maximizing extraction process efficiency, whether the process involves pressing or solvent extraction.

However, this measurement poses challenges for many methods as the oil content is relatively low and non-uniform, leading to significant sampling variation.

In addition, this sampling variation, as well as incomplete extraction, can introduce errors into the reference method. However, since NMR is non-destructive, the same sample can be measured by extraction after NMR analysis, avoiding sampling-related discrepancies.

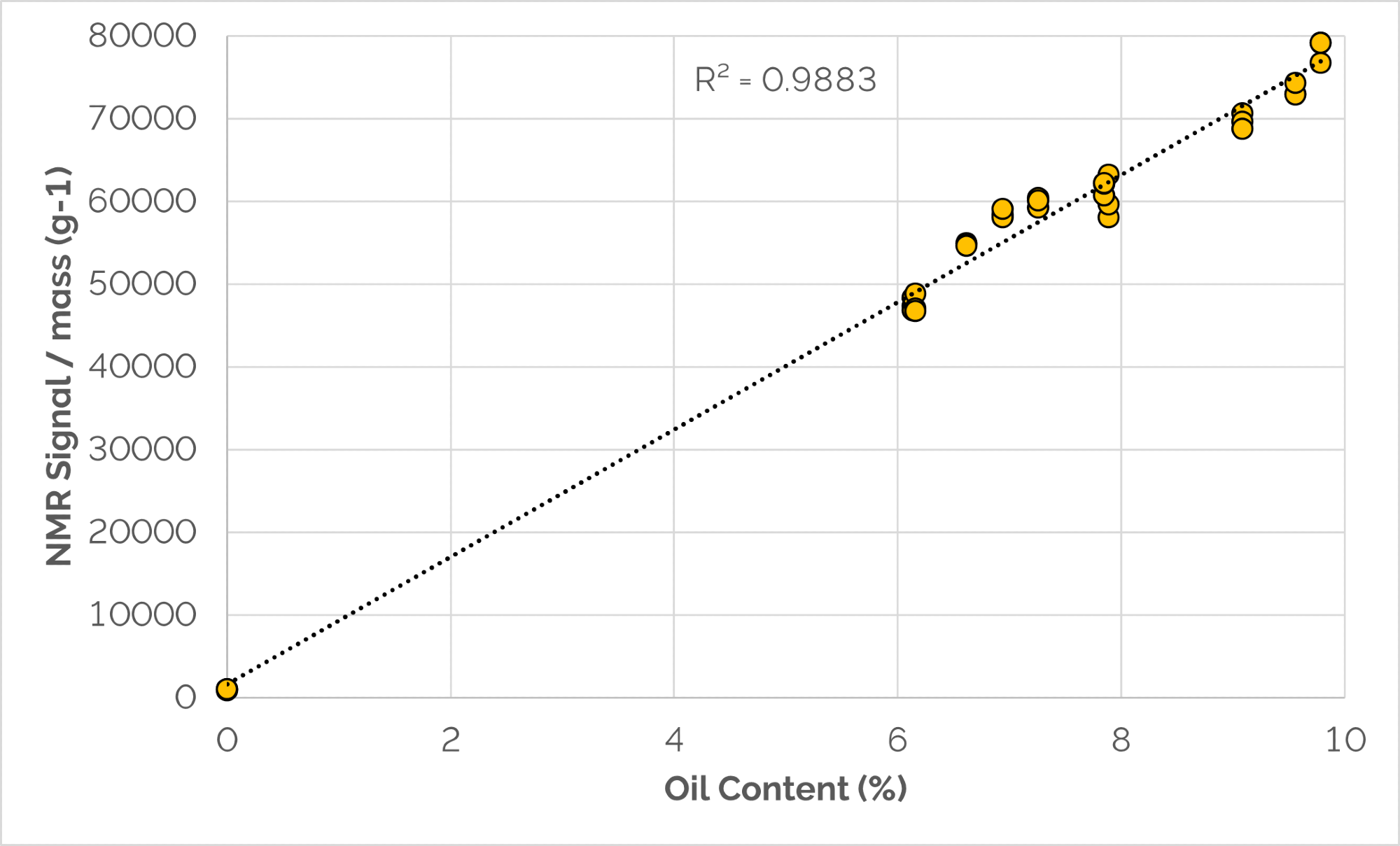

Figure 4 illustrates the correlation between the NMR signal/mass and the reference values determined on the same samples by Soxhlet (after drying). Therefore, as noted, any deviations between the results and the calibration line are likely due to errors caused by the reference method itself.

Figure 4. NMR calibration for oil in pressed palm fibre; the correlation coefficient and standard deviation are 0.99 and 0.28 % respectively. Image Credit: Oxford Instruments

Oil and Moisture in Palm Kernels and Palm Kernel Cake

Palm kernel crushers require rapid measurements of oil content to determine potential extraction amounts.

However, palm kernels are rarely measured due to the difficulty of crushing hard nuts into smaller pieces. Crushing is necessary to facilitate solvent penetration into the sample, improving extraction and leading to a more accurate result. Since the moisture content is relatively low, the oil content of palm kernels can be measured using NMR without drying.

Additionally, since radio frequency radiation penetrates the entire sample, NMR can measure palm kernels without crushing, provided they are conditioned at elevated temperatures to mobilize the oil before analysis.

NMR can also determine oil and moisture content in palm kernel cake, which is useful for monitoring the efficiency of the extraction process. Additionally, it can quantify the oil content in palm kernel meal, a byproduct used in animal feed.

Solid Fat Content

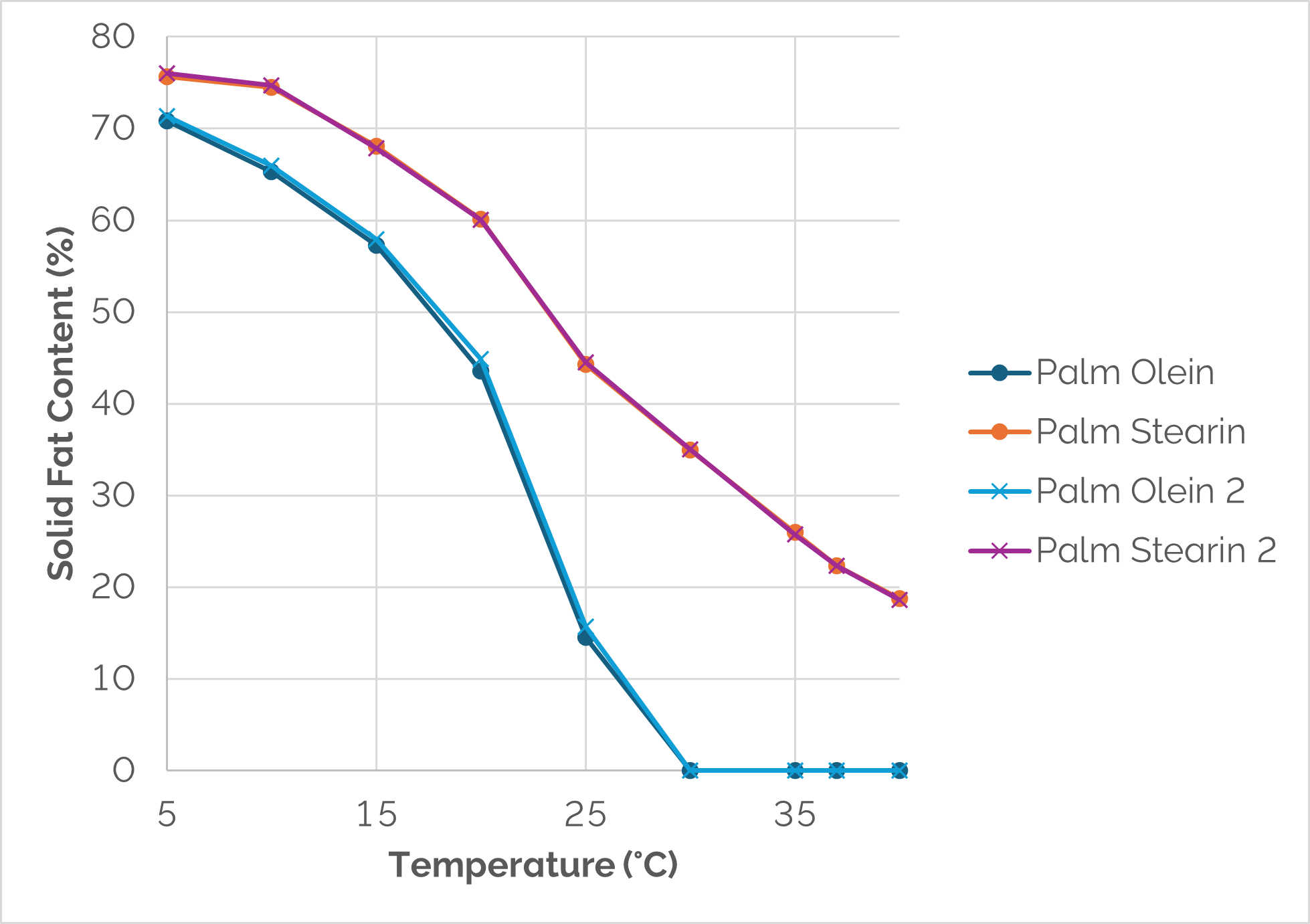

The melting profile of an edible oil is a function of its composition and is a key characteristic, as it defines the applications for which the oil and fats can be used as ingredients. Fortunately, TD-NMR can measure the proportion of solid fat in palm oil or its fractions when conditioned at different temperatures.

As this is a fundamental measurement, numerous standard techniques are employed globally by oil and fat companies for raw material characterization.7 The Direct method (AOCS Cd 16b-93, ISO 8292-1, IUPAC 2.150) is the most frequently employed thanks to its simplicity and accuracy. Figure 5 demonstrates that the melting profiles of palm olein and palm stearin measured using TD-NMR are highly reproducible.

Figure 5. The melting profiles from two sub-samples of palm olein and palm stearin. Image Credit: Oxford Instruments

Conclusions

Benchtop NMR can be employed at multiple stages of palm oil production, from measuring crop oil yield to raw material processing and characterization.

References and further reading:

- Iso.org. (2025). ISO Method 10565:1998 Oilseeds - Simultaneous determination of oil and water contents - Method using pulsed nuclear magnetic resonance spectrometry. Available at: https://www.iso.org/obp/ui/#iso:std:iso:10565:ed-2:v1:en.

- Iso.org. (2025). ISO Method 10632:2000 Oilseed residues - Simultaneous determination of oil and water contents - Method using pulsed nuclear magnetic resonance spectrometry. Available at: https://www.iso.org/obp/ui/es/#iso:std:iso:10632:ed-1:v1:en.

- Application Note 2: Measurement of Oil Content in Dried Snack Foods. Oxford Instruments 2023.Application-Note-02_Measurement-of-Oil-Content-in-Dried-Snack-Foods.pdf

- NMKL Method 199. Fat. Determination in fish, fish feed and fish meal by LF NMR. Method 199 - NMKL

- Junaidah, J., et al. (2011). Innovation for oil extraction method using NMR in bunch analysis. Souvenir programme-International seminar on breeding for sustainability in oil palm. November 18, 2011, KLCC Kuala Lumpur, Malaysia, ISOPB/MPOB. pp. 1–18.

- Application Note 18: Measurement of Oil Content in Dried Palm Mesocarp. Oxford Instruments 2018.MR_Mesocarp_App_Note.pdf

- Voda, M.A. and van Duynhoven, J. (2015). CHAPTER 3. Bench-top NMR - Food: Solid Fat Content Determination and Emulsion Droplet Sizing. New Developments in NMR, pp.86–109. DOI:10.1039/9781782628095-00086. https://books.rsc.org/books/edited-volume/49/chapter-abstract/59663/Bench-top-NMR-Food-Solid-Fat-Content-Determination?redirectedFrom=fulltext.

This information has been sourced, reviewed, and adapted from materials provided by Oxford Instruments.

For more information on this source, please visit Oxford Instruments.