Vegetable oils are utilized in various applications, including cooking, food ingredient formulations, margarine and shortening production, and the production of biofuels. They are produced through crushing and solvent extraction of oilseeds. The price and oil content of these oilseeds can vary due to several factors, such as harvest quality.

Image Credit: Nikifor Todorov /Shutterstock.com

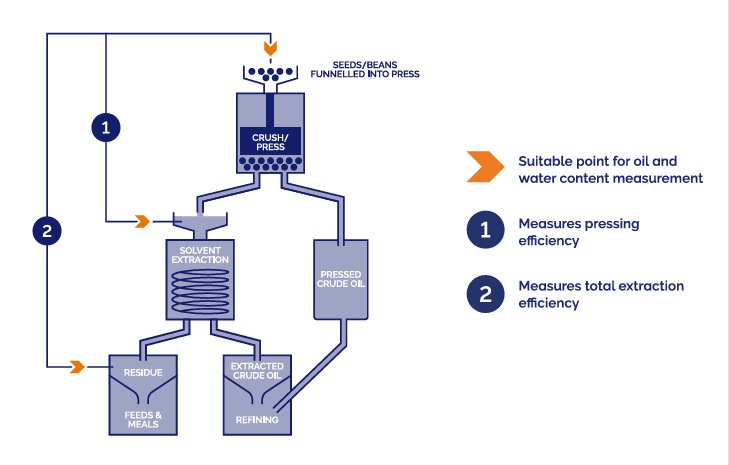

However, the final oil yield is also influenced by extraction process efficiency, which can be monitored by comparing the oil content of incoming oilseeds with the oil content of the residues after pressing and solvent extraction, as depicted in the diagram below.

Introducing the MQC+

The MQC+ oilseed analyzer accurately determines the oil and water content of oilseeds and residues in accordance with the ISO 10565 and ISO 10632 standard methods. The NMR measurement employs a simple and intuitive linear calibration that is unaffected by granularity, color, or seed origin.

Therefore, any decisions regarding oil content measurement, such as process optimization during crushing, can be made with confidence. Additionally, the MQC+ oilseed analyzer can measure the oil content of processed oilseed meal, which is subsequently used as animal feed.

Image Credit: Oxford Instruments

Simple and Transparent Calibration

The MQC+ oilseed analyzer requires calibration using at least three samples. A global calibration based on hundreds of samples is unnecessary, thereby eliminating extra calibration maintenance costs. Following the initial calibration, stable synthetic samples are employed to recreate the calibration over time.

Image Credit: Oxford Instruments

Increased Productivity

When using Soxhlet extraction methods, approximately one hour is required for a laboratory technician to prepare six samples for analysis, including cleaning afterwards (10 minutes of labor per sample). Extraction then takes an additional two hours, restricting one automated extraction system to analyzing 18 samples during a daytime shift.

The MQC+ software is ergonomically designed, allowing samples to be repeatedly weighed and subsequently analyzed without requiring a keyboard and mouse. The sample is poured into a tared tube, automatically weighed, then placed in the instrument for analysis.

Measurement requires only 16 seconds for the ISO methods. Preparation and analysis of each oilseed or residue sample takes only two to three minutes, allowing the MQC+ to analyze more than 250 oilseed samples per day, as would be required during the harvest season.

Image Credit: JIANG HONGYAN /Shutterstock.com

Reduced Material Costs

Although less costly per sample than labor expenses, solvent usage and disposal costs can be substantial for Soxhlet analysis. Generally, each sample requires 50 mL of petroleum ether, costing $20 per liter. Over a year, this can equate to:

18 samples/day x 365 days x $20 x 50/1000 L = $6,570 per year

Moreover, assuming disposal costs equal 20 % of solvent expenses, an estimated solvent cost for the Soxhlet extraction method reaches $7,884 per year. The MQC+ does not require solvents or any other consumables, relying instead on a mains power supply, while its supplied glass tubes can be reused.

Image Credit: Cast Of Thousands /Shutterstock.com

Process Efficiency

In addition to boosting laboratory efficiency, rapid and precise oil measurement provides the data required to maximize oil yield. For instance, if a rapeseed crushing facility producing 100,000 metric tons of oil per year increased its yield by 0.1 % through process optimization based on the oil content measurement, the NMR instrument would more than pay for itself within a year of operation (assuming a market value of $800 USD per metric ton).

Practical and financial comparison of Soxhlet and MQC+ oilseed analysis. Source: Oxford Instruments

| |

Soxhlet Extraction |

MQC+ Oilseed Analyser |

| Standard ISO method(s) |

Yes |

Yes |

| Daily sample throughput |

18 |

>250 |

| Annual solvent costs |

$6,570 |

$0 |

| Annual solvent disposal costs |

$1,314 |

$0 |

| Annual yield improvement value |

Not applicable |

$80,000 |

Image Credit: s_oleg /Shutterstock.com

Conclusion

In comparison to Soxhlet extraction methods, the MQC+ enhances oilseed and residue analysis through:

- Increased productivity and/or decreased labor expenses

- Lowered consumable costs

- Enhanced crushing yield due to a timely and precise response.

In comparison to near infra-red analysis, the MQC+ provides:

- A simpler and intuitive calibration process, independent of sample origin and physical characteristics

- No extra calibration maintenance expenses

- Enhanced crushing yield thanks to more precise measurements.

This information has been sourced, reviewed, and adapted from materials provided by Oxford Instruments.

For more information on this source, please visit Oxford Instruments.