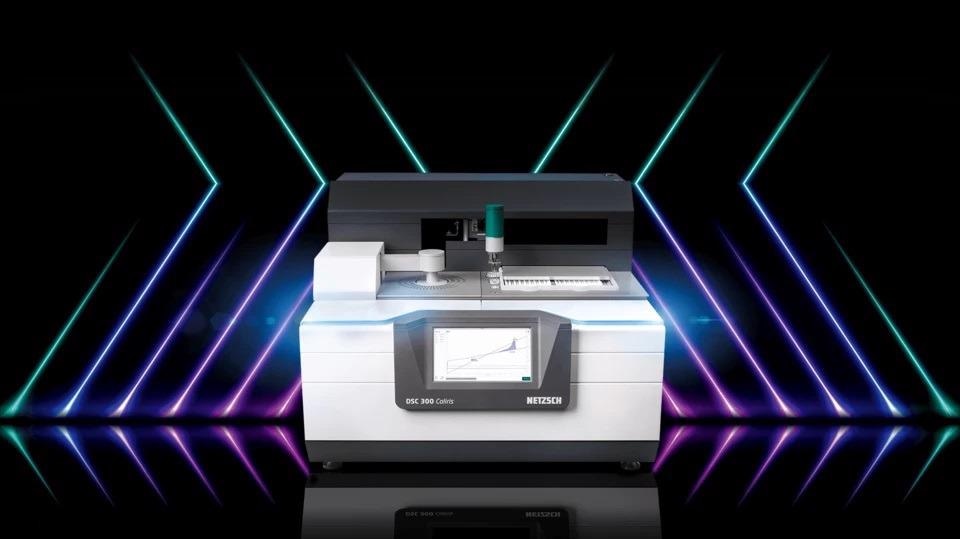

The NETZSCH DSC 300 Caliris® is the foremost choice for material characterization due to its unparalleled comprehensiveness, reliability, and versatility.

Information on a material’s behavior in various temperatures and atmospheres is important, regardless of whether users are involved in research and development, quality control, contract testing, or the specification of materials for a few applications.

The DSC 300 Caliris® supports:

- Material identification

- Quality control

- Phase diagrams

- Compatibility

- Kinetic analysis

- Process optimization

Modular Design — Maximum Flexibility

Rapid advancements in technology and mobility have sped up the development of new materials, necessitating constant adaptation. The modular concept forms the basis of the latest generation of NETZSCH DSCs.

The only device with interchangeable and swappable sensor-furnace modules is the DSC 300 Caliris®. The outstanding DSC 300 Caliris® model allows for module swapping, allowing it to adjust to both current and future needs.

The DSC 300 Caliris® Supreme — The Future-Proof Choice

This version offers three module options and can be set up to achieve an unparalleled maximum temperature range of –180 °C to 750 °C. Users can change their applications or take advantage of new technological advancements by updating their devices at any time.

The module that is used can be chosen indefinitely. Users only need to choose between high sensitivity, wide temperature range, or quick heating rates when needed.

The DSC 300 Caliris® Select — Tailor Made for Applications

There is an initial option to select from three currently available modules in the DSC 300 Caliris® Select version. The DSC 300 Caliris® Select can withstand temperatures as high as –170 °C to 650 °C. To avoid instrument downtime, the Select version allows the interchange of identical-type modules.

Both variants have an integrated color touch display and an LED status bar. If preferred, an automatic sample changer can be added.

H-Module

Video Credit: NETZSCH-Gerätebau GmbH

High-Performance Module −180 °C to 750 °C

The premium module is the industry standard for most DSC applications because it offers the highest sensitivity, accuracy, and a very small peak-to-peak noise ratio. It also impresses with an ideal baseline and excellent reproducibility.

When used in conjunction with the Supreme version, this module can withstand temperatures ranging from –180 °C to 750 °C. For advanced materials research and development in both academia and industry, the H-Module is the ideal adjunct.

P-Module

Video Credit: NETZSCH-Gerätebau GmbH

The Polymer-Module −170 °C to 600 °C

This module is perfect for every task in the field of polymers. Over a wide measurement range, its enhanced low-mass furnace allows for heating rates of up to 500 K/minute. It is possible to identify temperature profiles that approach actual processing conditions.

It is possible to expedite the measurements, saving valuable time. The P-Module is perfect for quality assurance and research and development in polymer processing.

S-Module

Video Credit: NETZSCH-Gerätebau GmbH

The Standard Module −170 °C to 600 °C

Improved thermal effect resolution and high stability are integrated into the routine module. For the sensor disks and thermocouple wires, laser-guided welding processes offer true robustness and sensitivity.

Metrological stability and high optimal resolution are features of the monolithic DSC sensor. When routine measurements are the main task, industry and contract laboratories prefer using a user-friendly S-module handle.

Keynote – Caliris® Supreme and Select

KEYNOTE: Differential Scanning Calorimeter - DSC 300 Caliris Supreme & Select

Video Credit: NETZSCH-Gerätebau GmbH

Technical Data DSC 300 Caliris®

- Automatic sample changer 192 + 12 positions

- The maximum heating rate is 0.001 K/minute to 500 K/minute

- The maximum temperature range is from −180 °C to 750 °C

DSC 300 Caliris Supreme & Select

Video Credit: NETZSCH-Gerätebau GmbH

- Gas atmospheres: Inert, dynamic, oxidizing, and static

- Temperature accuracy (H-Module): ± 0.05 K (Indium)

- Enthalpy precision (H-Module): ± 0.05% for indium

- Repeatability: ± 0.3% (peak area; In, C10H16, Zn)

- Temperature precision (H- and P-Module): ± 0.01 K (standard deviation from the mean value, indium)

- Peak-to-peak noise ratio: ± 2 µW

Image Credit: NETZSCH-Gerätebau GmbH

Cooling Options

- IC90 (−90 °C to 600 °C)

- Compressed air cooling (RT to 650 °C/750 °C)

- IC40 (−40 °C to 600 °C)

- Compressed air with switch valve RT to 650 °C/750 °C

- LN2 (−180 °C to 650 °C/750 °C)

- Vortex tube (compressed air): <0 °C to 650 °C/750 °C

- IC70 (−70 °C to 600 °C)

Heating/Cooling Rate

- S-Module: 0.001 K/minute to 100 K/minute

- H-Module: 0.001 K/minute to 200 K/minute

- P-Module: 0.001 K/minute to 500 K/minute (Maximum rates depend upon end temperature)

Sensor Guide Light. Image Credit: NETZSCH-Gerätebau GmbH

Proteus® Software - The Easy Approach to Users’ Work

Proteus®: Excellent Thermal Analysis Software

With Proteus® software running on Windows, the DSC 300 Caliris® has all the components users require to measure and evaluate the data produced. Even for complex tasks, data interpretation is straightforward, thanks to the combination of automated processes and user-friendly menus.

The instrument has been used to license the Proteus® software, which can also be installed on other computer systems.

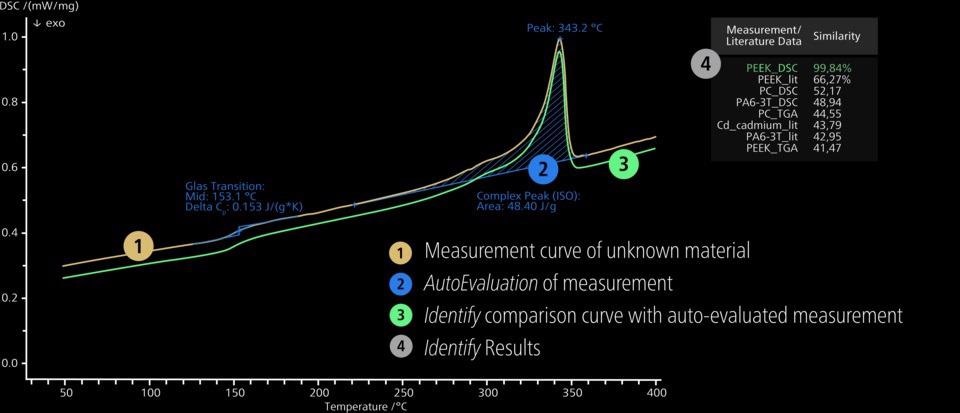

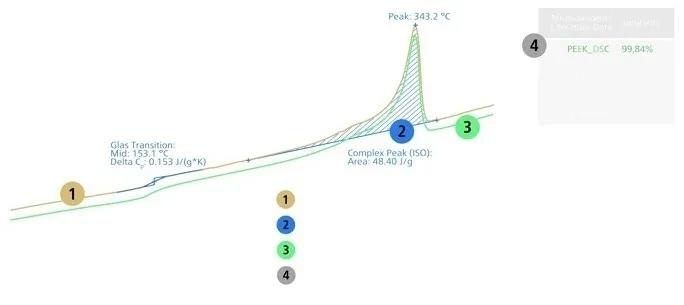

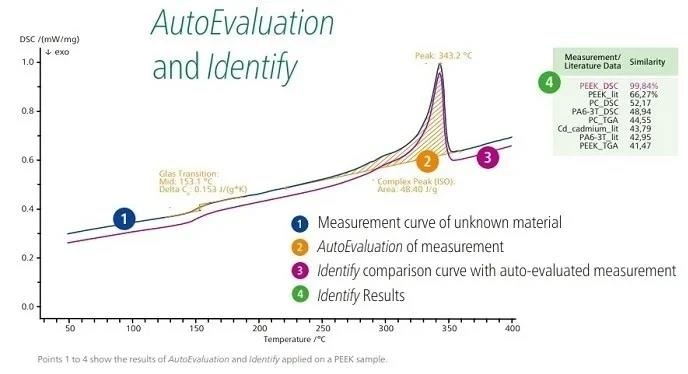

AutoEvaluation

AutoEvaluation is regarded as intelligent software that makes it possible to assess unknown curves automatically or by simply pressing a button. To analyze DSC curves, AutoEvaluation first locates any major effects, such as melting peaks or glass transitions.

In addition, it provides a logical interpretation of side effects such as recrystallization effects. Initially, a clever software algorithm gives users access to professional application knowledge.

Identify

With database comparison, measurements can be classified using a unique software tool called Identify. In addition to facilitating one-on-one comparisons with distinct curves and literature data, it can potentially determine whether a unique curve is a member of a particular class. Curves of the same material type (material identification) or reference curves for test pass/fail outcomes (quality control) can be included in these classes.

Over 1300 entries related to different application areas such as polymers, pharmaceuticals, organics, inorganics, metals or alloys, and ceramics are included in the NETZSCH libraries.

Moreover, the DSC curves for an additional 1100 commercially available polymer types are included in the KIMW database. Users can add as much of their data as they would like to Identify by expanding it as far as they can. Generally, every database entry serves as a pool of results and practical measurement conditions.

Image Credit: NETZSCH-Gerätebau GmbH

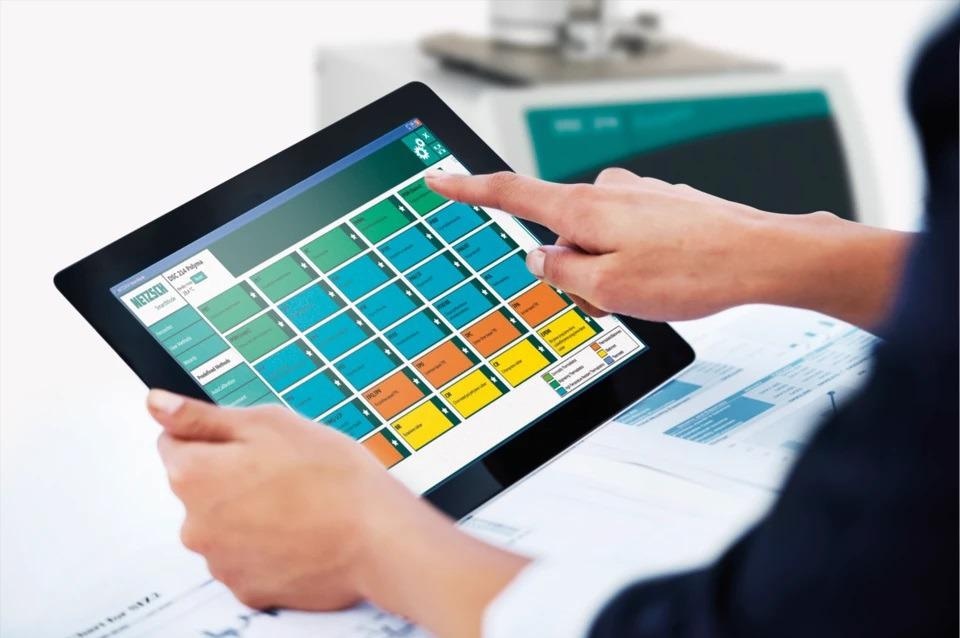

SmartMode vs ExpertMode

SmartMode was created for routine measurements that align with quality control standards. Tasks utilizing precisely defined measurement procedures facilitate quick and easy preparation and the beginning of measurements. Helpful aides include user-defined or pre-defined measurement techniques and wizards (quick-start routines).

ExpertMode provides a wealth of options. This mode was created for users who wish to use all of Proteus® capabilities. It offers limitless capability and is perfect for complex measurement tasks.

SmartMode and ExpertMode are commonly found next to each other and are considered part of the Proteus® software’s standard configuration.

Image Credit: NETZSCH-Gerätebau GmbH

Proteus® — My Workspace

Managing all of the functions accessible when using Proteus® analysis might be overwhelming. Proteus® Workspaces allow users to tailor the Proteus® analysis menu and toolbar icons to their regular routines.

Users can change the arrangement so that everything they use most often is at the front, hide settings they seldom or never use, and save their favorite configuration as their workspace. For workstations shared by several users, this is advantageous. Custom and shared workspaces are simple for users to switch between.

Proteus® - Search Engine

Database Capability without the Need to Own a Database License

Filtering by specific criteria is helpful when working with measurement and evaluation data from different measurement setups and materials. In a matter of seconds, the Proteus® Search Engine filters the measurement data of users. It is a powerful tool for data mining. Previews of the analysis status or measurement curves are automatically displayed after selection.

The file system allowed users to open folders with a single button click. Users can quickly switch between active searches and create separate searches, such as “MyPolymers.”

Filters can be set by:

- File

- Instrument type

- Sample name

- Evaluated effects

- Peaks

- Onset temperature

- Date of measurement

Image Credit: NETZSCH-Gerätebau GmbH

LabV Primed

LabV Primed - Enter the Digital Lab

In analytical laboratories, the amount of data being recorded is constantly growing. Future laboratories will be end-to-end linked environments with people, devices, and systems.

Optimizing laboratory workflow requires constant monitoring of and organizing collected data so that it is available for comparison, final reports, and experiments in the future. Forecasts based on gathered data contribute to improved part, process, and quality performance, making next-generation laboratories extremely effective.

LabV-primed NETZSCH DSC 300 Caliris® is included. The LabV cloud solution connects all systems and devices, regardless of manufacturer, and stores all laboratory data in one location.

Easy-to-read documentation gives users more time to run tests and analyze the data. LabV® connects all of the analysis methods, bringing transparency to the procedures. As a result, there is greater flexibility in projects and consistency in product quality.

Image Credit: NETZSCH-Gerätebau GmbH

Control Over Users’ Measurements Without Logging Into the PC

LED Status Bar

With the LED light bar on the DSC 300 Caliris®, users can check the status of their instrument as they pass by, and the color will change accordingly. It is consoling to be able to view their measurement from a distance and to read notifications about the status of the instrument, such as:

- The instrument is all set

- Measurement is running

- User interaction required

- Measurement is in progress

- Heating or cooling to setpoint

Image Credit: NETZSCH-Gerätebau GmbH

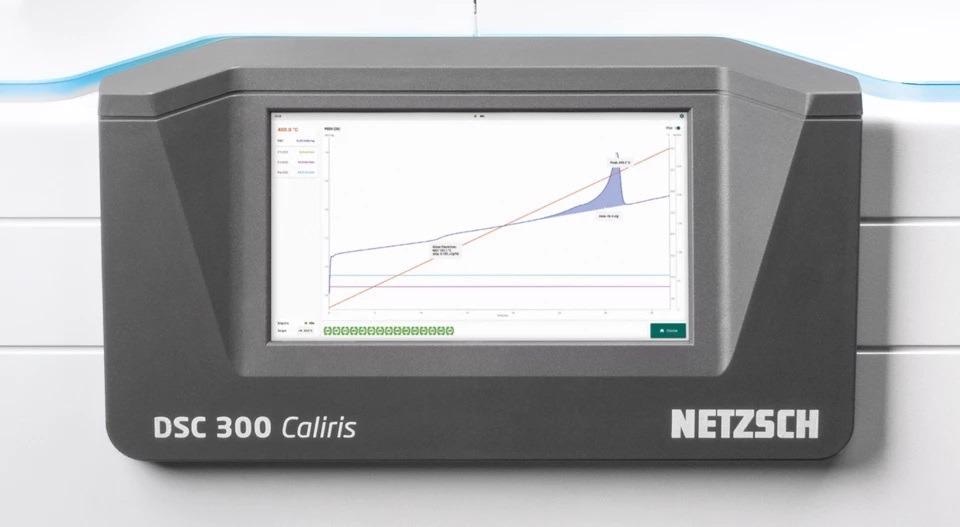

Integrated Touch Display

Control Over Measurements Without Logging Into the PC

Thanks to the integrated color display, users can start a measurement that was previously made in the NETZSCH Proteus® software. Simply touching the inclined measurement button on the display will provide users with information on how to set up the measurement correctly.

This immediately moves the last check to the instrument before the start of a new measurement. With the color touch display, users can:

- Begin measurements with a finger touch

- Follow the measurement progress

- Users can verify the execution list for newly completed measurements

- Obtain an instant overview of the analyzed measurement findings

- Check gases, idle states, and the current temperature

- See how measurements are progressing and how much time is left

Image Credit: NETZSCH-Gerätebau GmbH

DSC 300 Caliris® Classic for Differential Scanning Calorimetry

The cutting-edge DSC 300 Caliris® Classic is reliable, accurate, robust, and designed with everyday use in mind. Whether the user is a novice or a seasoned professional, this instrument’s unique design includes everything needed for effective DSC investigations.

The ground-breaking software creates new benchmarks: the proven AutoEvaluation and Identify presently complete the next generation of LabV® data management, which tracks the collected data and organizes it for an efficient workflow in the laboratory.

The DSC 300 Caliris® Classic provides:

- Automated measurement and evaluation, making routine simple

- A small design for more space in users’ laboratory

- Smart software that enables users to begin quickly with DSC measurements

DSC 300 Caliris Classic

Video Credit: NETZSCH-Gerätebau GmbH

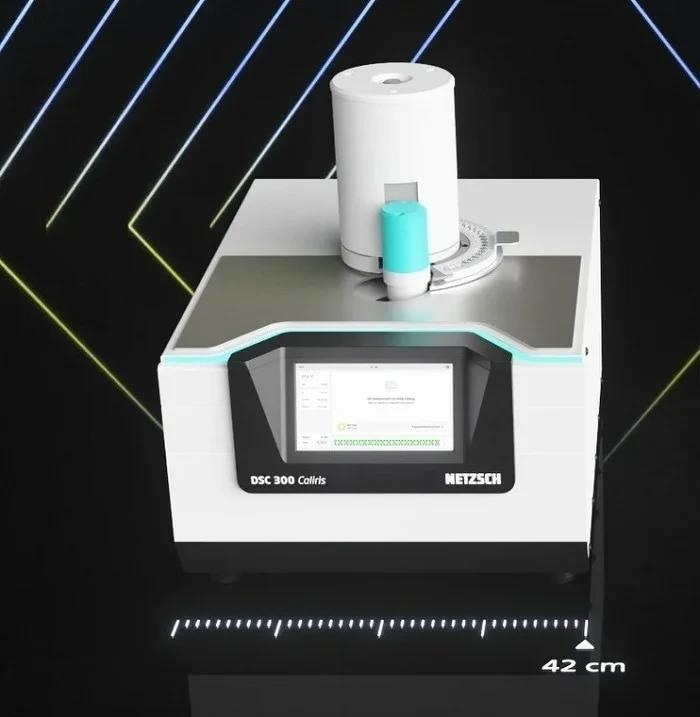

Compact Lab Instrument

Typically, laboratory space is very expensive. Thus, the DSC 300 Caliris® Classic is a great option because of its compact design and cooling accessories like the intracooler. It is perfect for online testing and is simple to set up for QA or QC in a production setting.

Image Credit: NETZSCH-Gerätebau GmbH

Touch Display for Improved Productivity and Workflows

The DSC 300 Caliris® Classic offers an optional integrated touchscreen display with complex instrument and measurement information in addition to the standard display.

From the touch display, a measurement taken with the assistance of the Proteus® software can be initiated immediately. Without requiring access to a PC, the touch display provides up-to-date measurement information once a measurement is ready.

Image Credit: NETZSCH-Gerätebau GmbH

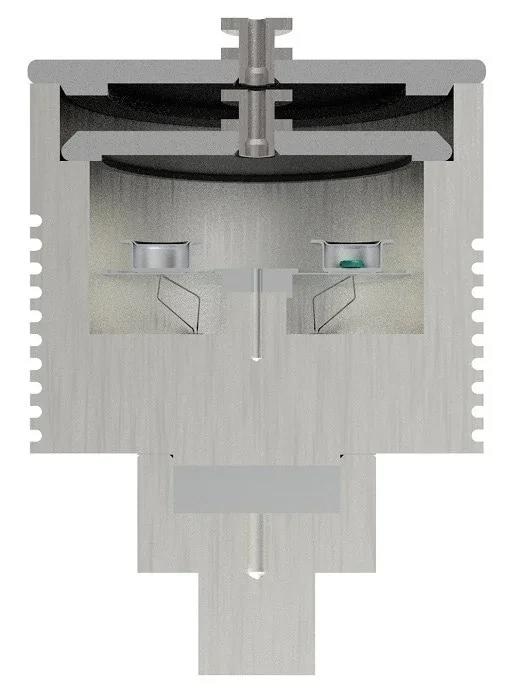

Excellent Performance Even in Less-Than-Perfect Environments

The monolithic DSC sensor provides optimal resolution and is stable in challenging conditions. Laser welding provides high sensitivity and durability to the thermocouple wires and sensor disks.

A glass fiber brush can also be used to clean the sensor. The temperature range of up to 600 °C allows easy cleaning by baking out the contaminants in the event of unwanted cell or sensor contamination. Connectors with clever designs allow for quick and easy installation of various cooling systems.

Ideal Combination of Furnace, Sensor, and Crucible. Image Credit: NETZSCH-Gerätebau GmbH

The Future is Now

Users can bring the devices inside their laboratory with a single button.

Users can instantly access a 3D model of the instrument on their smartphones or tablets by scanning the QR code. The most recent advancements in artificial reality (AR) technology enable users to place the 3D model in their laboratory at its original size. No app is needed for this browser-based feature.

Image Credit: NETZSCH-Gerätebau GmbH

Technical Data

Temperature Range

Automatic Sample Changer

- For up to 20 samples and references

Heating/Cooling Rate

Enthalpy Precision

Specific Heat Determination

Temperature Modulation

Gas Atmospheres

- Inert, static, oxidizing, and dynamic operation

Automatic Sample Changer (ASC)

- Up to 20 samples and references, optional available

Cooling Device Options

- Compressed air cooling (RT to 600 °C)

- IC40 (−40 °C to 600 °C)

- IC70 (−70 °C to 600 °C)

- LN2 (−170 °C to 600 °C)

Indium Response Ratio

- >100 mW/K (Mean value, connected indium as standard material under measurement conditions normally utilized for polymer investigation)

Heating/Cooling Rate

- K/minute to 100 K/minute (Maximum rate relies on temperature)

Image Credit: NETZSCH-Gerätebau GmbH

Image Credit: NETZSCH-Gerätebau GmbH

Software Proteus®

Get Started Quickly With SmartMode

With its well-thought-out design and stable framework, the system’s SmartMode interface ensures straightforward navigation and ease of use—even for inexperienced users. Users can obtain the information they require quickly and efficiently through its user-friendly interface.

Instant measurements with just one click are made possible by the Wizards menu, which offers a large selection of pre-configured measurement templates requiring the least input.

Users can find a list of all the materials included in the NETZSCH Thermal Properties of Polymers—which can also be found on the NETZSCH Polymer Poster—as well as the corresponding, specifically designed for experimentation measurement techniques in the Predefined Methods section.

Users can use the User Methods menu to store previously used techniques as templates for upcoming measurements. This simplifies the process by eliminating the need to frequently redefine the measurement parameters.

AutoEvaluation

With the help of intelligent software called AutoEvaluation, unknown curves can be evaluated automatically or by pressing a button.

When analyzing DSC curves, AutoEvaluation first finds any critical effects, such as melting peaks or glass transitions, and then correctly renders side effects, such as recrystallization effects, in a logical sequence.

Initially, an intelligent software algorithm provides users with expert application knowledge.

Image Credit: NETZSCH-Gerätebau GmbH

Identify

Identify is a special software application that uses database comparison to classify and identify measurements. It allows for one-on-one comparisons with individual curves and literature data and determines whether a given curve is part of a few classes.

These classes consist of reference curves for Pass/Fail testing (quality control) or curves of the same material type (material identification).

Approximately 1300 entries are available in the NETZSCH libraries about various application areas, including pharmaceuticals, polymers, inorganics, organics, metals/alloys, and ceramics.

The DSC curves for an additional 1,150 commercially available polymer products are included in the KIMW database. Users can add infinite data to Identify by expanding it as they see fit. All database entries typically function as a pool of results and advantageous measurement conditions.

Image Credit: NETZSCH-Gerätebau GmbH

LABV®

LabV®®-Primed-Enter the Digital Lab

The amount of data being recorded in analytical laboratories is constantly growing. In the future, laboratories, people, devices, and systems will all be connected end to end.

Simplifying laboratory workflows requires tracking and organizing data from analytical instruments for follow-up experiments, final reports, or comparisons. Forecasts grounded in gathered data improve component, process, and quality performance, resulting in an extremely effective future laboratory.

The NETZSCH DSC 300 Caliris®® is primed with LabV®®. Using the optional LabV®® cloud solution, users can connect all their devices and systems, regardless of manufacturer, and keep all their laboratory data in one location.

More time is available for testing and data interpretation when documentation is easily done. Since LabV®® connects all the analysis techniques, procedures are transparent. Projects are very flexible, and the caliber of the final product is consistent.

PROTEUS® Search Engine

The broad search capability of Proteus® Search Engine improves users' efficiency and effectiveness when completing analysis tasks and data exploration. It provides several practical features to enhance data handling.

Users can efficiently organize and navigate via their stored information and quickly access and sort data based on specified criteria. Additionally, the system provides a preview feature that enables users to see their data without opening individual files.

This preview feature extends to measurements and analyses, allowing users to evaluate their contents quickly and easily without having to open files one by one. Strong search capabilities provided by the system enable users to find data quickly using various criteria, including instrument name, operator, file, method, signal type, date, measurement conditions, or evaluated effects.

AutoCalibration

Appropriate DSC measurements require the DSC instrument to be calibrated. It ensures that the instrument will consistently measure within predetermined bounds. However, the calibration procedure must be simple, fast and ideally carried out with the procedure.

AutoCalibration provides a solution for this. This special software-developed function starts the calibration measurements and offers pre-defined calibration methods for common standards. Additionally, it computes calibration curves, automatically analyzes melting peaks, and verifies the accuracy of the results.

A routine task that could otherwise be extremely laborious is made simpler by Autocalibration.