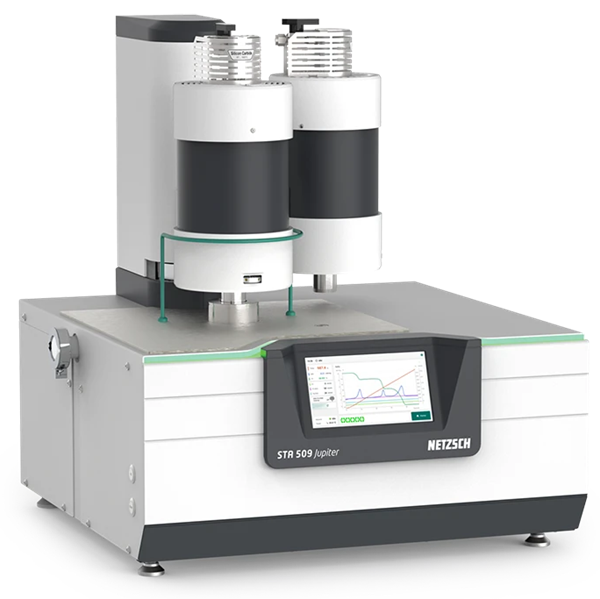

The STA 509 Jupiter® Classic is the most cost-effective option for regular high-performance simultaneous thermal analysis because it provides outstanding value. Featuring a silicon carbide furnace capable of reaching 1600 °C and differential scanning calorimetry capabilities, this versatile instrument excels in typical applications such as thermal stability, phase transitions, oxidation/reduction reactions, and decomposition processes across diverse materials and industries. Using its sturdy design and state-of-the-art technology, the STA 509 Jupiter® Classic offers dependable precision, accuracy, and repeatable results despite its exceptional price/performance ratio.

Image Credit: NETZSCH-Gerätebau GmbH

Simultaneous Thermal Analysis - STA 509 Jupiter® Series

Video Credit: NETZSCH-Gerätebau GmbH

Improving Productivity and Workflow by Design

With its integrated color display and one-touch activation of pre-programmed measurements, the STA 509 Jupiter® streamlines thermal analysis. Thanks to its LED light bar offering color-coded indicators and an easy-to-read display of the instrument status, users can remotely monitor measurements without using a PC. This practical design streamlines the workflow and keeps the user informed.

Top Loading Balance Design

The top-loading, electronically compensated design provides optimal performance and ease of use. It is the best option for evolving gas analysis and flexible analytical systems.

Defined Atmospheric Conditions

The careful gas flow control and vacuum-tight construction allow for accurate handling of high-purity atmospheres, such as corrosive, oxidizing, reducing, and inert gases.

Precision and Accuracy

High-performance heat flux DSC, in conjunction with nanogram balance, offers unparalleled flexibility for large sample loads and outstanding accuracy with very little drift.

Image Credit: NETZSCH-Gerätebau GmbH

Eco-Friendly Performance

While lowering energy and gas consumption for significant savings and promoting sustainability, the electronic thermal stabilization and Eco Mode maximize efficiency and deliver peak performance.

Accessories and Evolved Gas Analysis

Different sample holders expand the range of applications. The STA 509 Jupiter® Classic's analytical capabilities are developed by integrating evolved gas analysis with MS, FT-IR, or GC-MS.

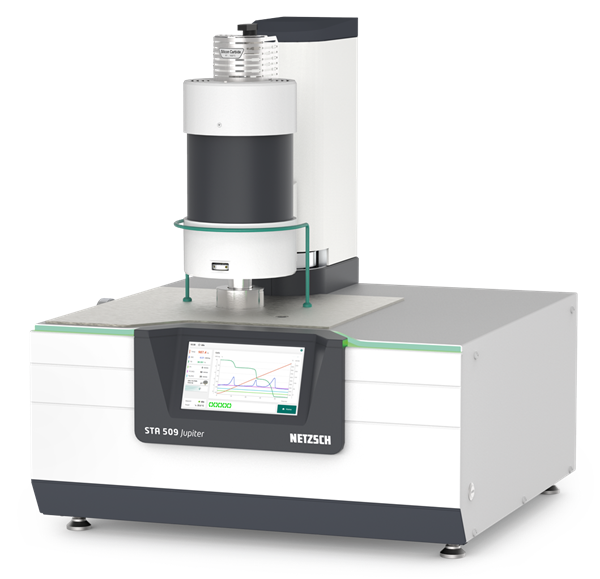

The STA 509 Jupiter® Series

The STA's modular design makes it simple to swap out furnaces and sensors for various applications over a broad temperature range of -150 °C to 2400 °C. The top-loading design is the clear choice for a versatile analytical system and evolved gas analysis because it offers optimal performance and ease of use.

The vacuum-tight design and careful control of gas flows make the precise handling of high-purity atmospheres possible for various inert, oxidizing, reducing, and corrosive gases.

Numerous add-ons, such as water vapor and humidity generators, increase the potential applications. Moreover, integrating evolved gas analysis with MS, FT-IR, or GC-MS systems greatly increases the analytical capability of the STA 509 Jupiter® series.

STA 509 Jupiter Select

Image Credit: NETZSCH-Gerätebau GmbH

Tailored to User's Needs

- Balance resolution: 0.1 μg

- Optional 20-position ASC or second furnace

- 150 to 2400 °C

- Choice of 12 different furnaces

STA 509 Jupiter Supreme

Image Credit: NETZSCH-Gerätebau GmbH

Instrument for Highest Performance

- Optional 20-position ASC or second furnace

- 150 °C to 2000 °C

- Choice of nine different furnaces

- Balance resolution: 0.025 μg

Method

Simultaneous Thermal Analysis

Simultaneous Thermogravimetry (STG) is a method used to analyze the thermal stability and composition of materials simultaneously. It combines two methods: Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA).

By measuring a material's weight change in response to heat or cold, TGA can determine a material's moisture content, thermal stability, and decomposition temperature. DSC offers information on phase transitions, heat capacity, and reaction enthalpies by measuring the quantity of heat needed to raise a sample's temperature.

STA combines these two measurement methods by recording a sample's weight change and heat flow.

A tiny quantity of the substance is heated or cooled after being put in a particular container. The STA device records the weight variations and the heat that the sample absorbs or releases. This method is beneficial because it provides detailed data on a material's thermal properties and composition, and its efficiency saves both time and sample material.

STA is employed in failure analysis, research and development, and quality control. It is a vital tool for scientists and engineers because it is necessary for researching how polymers, medications, food, and other materials behave at various temperatures.

Image Credit: NETZSCH-Gerätebau GmbH

Measuring Principle

Simultaneous Thermal Analysis operates as follows:

- Sample Preparation: A small amount of the material (sample) is placed in a special container known as a crucible.

- Heating/Cooling: The sample is heated or cooled at a controlled rate during the analysis.

- Measurement: As the temperature changes, the STA instrument records

- Weight change: How much the sample's weight increases or decreases.

- Heat flow: How much heat is absorbed or released by the sample.

Possibilities Through Differential Scanning Calorimeter

There are various thermophysical properties can be measured using Differential Scanning Calorimetry:

- Specific heat capacity

- Solid-solid transitions

- Melting/crystallization behavior

- Degree of crystallinity

- Polymorphism

- Glass transitions

- Oxidative stability

- Purity determination

- Thermal simulations

- Cross-linking reactions

- TM-DSC

- Kinetics simulations

Possibilities Through Thermogravimetry

The following thermophysical properties can be measured using Thermogravimetry:

- Mass changes

- Oxidation/reduction behavior

- Decomposition

- Corrosion studies

- Temperature stability.

- Kinetics simulations

- Compositional analysis

- Thermal simulations

Specifications

Temperature Range

RT to1600 °C

Balance Performance

Balance resolution of 0.1 μg over the complete mass range of 35 g

DSC Performance

DSC enthalpy accuracy: 1%(Indium)

Discover the carefully tailored Simultaneous Thermal Analyzer designed to meet user needs:

Image Credit: NETZSCH-Gerätebau GmbH

- Heating rate: 0.001 to 50 K/min

- Temperature resolution: 0.001 K

- Various Sensor Options: TGA, TGA-DTA, TGA-DSC

- Optional 20-position ASC

Day-to-Day Workhorse

Image Credit: NETZSCH-Gerätebau GmbH

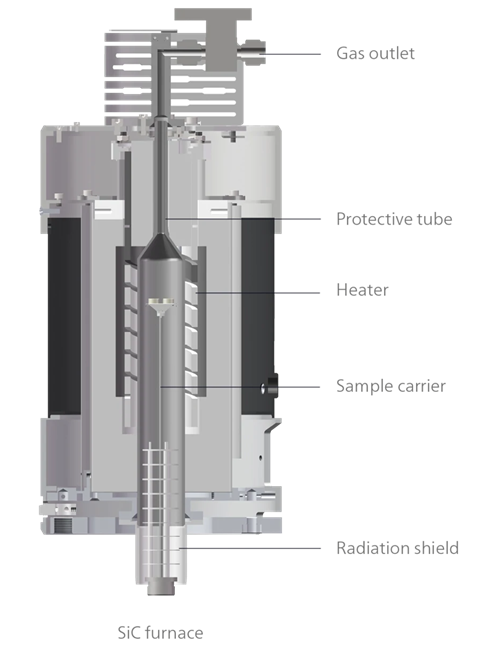

The sturdy workhorse of the STA 509 Jupiter®, the silicon carbide furnace, runs at temperatures between room temperature and 1600 °C. Because it has an aluminum oxide protective tube, it can handle corrosive environments and aggressive samples. Its user-friendly design allows operators to easily replace tubes, ensuring minimal downtime.

Eco Mode - Thermal Analysis Made More Sustainable

70% Less Energy and Cost – No External Temperature Control Needed

Most manufacturers must use thermostatic control with a water circuit to obtain low drift behavior thermogravimetric results. Running the thermostat nonstop uses a lot of energy and generates waste heat, which needs to be controlled by air conditioning.

NETZSCH removed the external thermostat. An electronic system currently regulates the weighing chamber's temperature while preserving superior temperature stability. When an STA 509 Jupiter® is used three times a day, 250 days a year, the average user's energy consumption is reduced by 70% by turning off the thermostat. This results in an annual savings of 5000 KW/h of electricity. Using the Eco Mode, which shuts off the gases when they are not needed, is another way to operate the unit more economically. This lowers the unit's operating costs and reduces the carbon footprint.

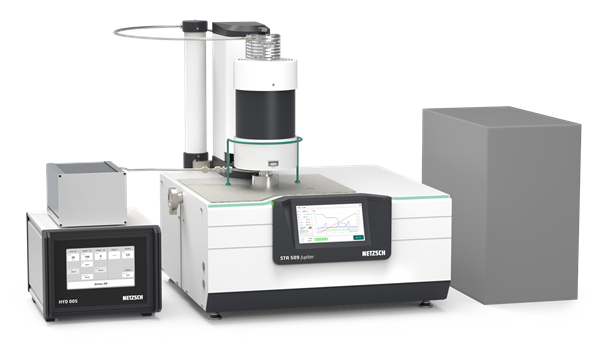

Hydrogen Research with Thermal Analysis

Image Credit: NETZSCH-Gerätebau GmbH

The potential application of hydrogen (H2) in green technology and sustainable practices is drawing increasing attention. Investigating how materials react with hydrogen is essential to creating environmentally friendly products with minimal negative environmental impact.

One noteworthy use is the reduction of high CO2 emissions from metallurgical processes—like the reduction of iron ore—by direct reduction using hydrogen.

NETZSCH's H2Secure concept offers a comprehensive solution that ensures maximum safety when conducting tests in environments with different hydrogen concentrations. This flexibility is made possible by a thorough safety protocol integrated into the system, which allows for the smooth execution of intricate cycles involving oxidation and reduction as well as accurate analysis of reaction kinetics and material behavior under various circumstances.

- The volume of H2 is precisely controlled by adding hydrogen at the top of the furnace and limiting it to a specific area above the continuously purged balance chamber.

- For safe handling, H2 and O2 gas concentrations are continuously monitored.

- The H2 Secure box, the central communication unit, processes all the data and regulates the gas flows according to predetermined safety limits.

- To achieve fail-safe operation, the magnetic valves are opened during a power outage, releasing an inert gas that expels hydrogen from the system.

Evolved Gas Analysis

Thermal analysis instruments have an important feature that allows them to be used with EGA techniques. EGA is a potent instrument that improves the functionality of thermal analysis by allowing for the in-depth examination of the gases that are evolved during heating and cooling. This coupling makes a thorough understanding of materials' thermal behavior and composition possible.

NETZSCH provides coupling alternatives with mass spectrometry (MS), gas chromatography-mass spectrometry (GC-MS), and Fourier transform infrared spectroscopy (FT-IR). Each method has special benefits.

Through the integration of these cutting-edge EGA techniques with thermal analysis instruments, NETZSCH guarantees that the data it receives for its research and development needs is accurate and comprehensive. Its dedication to quality and innovation ensures that the instruments will live up to the highest expectations.

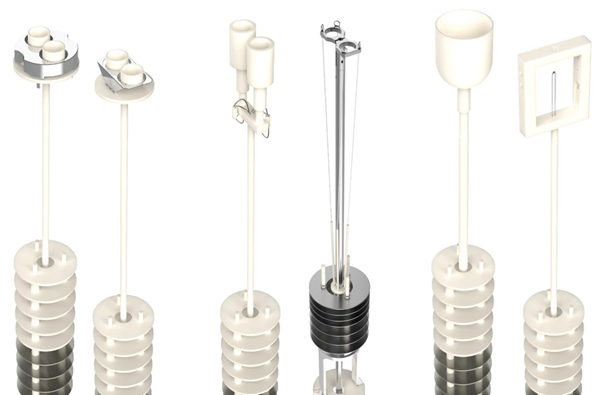

Discover Many More Features

The STA 509 Jupiter® series features an interchangeable sensor system that enhances versatility and adaptability in experimental setups. Researchers can tailor testing approaches to match specific sample characteristics, environmental conditions, and research objectives. The Quick-Connect feature allows for sensor changes in seconds, facilitating seamless adaptation of the system to various applications and maximizing testing system utility and effectiveness.

NETZSCH offers a variety of thermocouples (S, P, E, K, W, etc.) suitable for a wide range of applications.

TGA-DSC and TGA-DSC (cp) sensors provide quantitative DSC testing in addition to TGA results, enabling comprehensive thermal analysis. The cp versions specifically allow for highly accurate determination of the specific heat capacity, improving the precision of thermal measurements.

TGA-DTA sensors simultaneously measure weight changes and qualitative energetic effects, which is ideal for cost-effective routine tests. This technology is adaptable to operate under extreme conditions, including corrosive atmospheres and temperatures up to 2400 °C.

The TGA sensor allows precise measurement of mass changes and offers versatility to accommodate various sample shapes and volumes. Special versions with suspended or net-shaped samples support optimizing sample-gas interactions for efficient analysis.

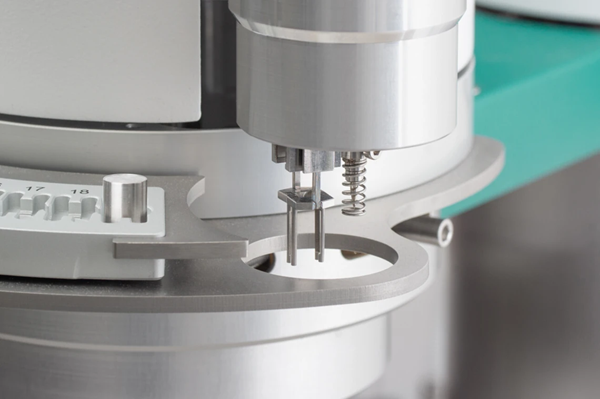

Image Credit: NETZSCH-Gerätebau GmbH

An optional automatic sample changer for up to 20 samples is available, designed for optimal crucible placement and high throughput. Preprogramming enables measurements to be conducted overnight or on weekends. The software can automatically execute analyses using either automatic or predefined evaluations.

Image Credit: NETZSCH-Gerätebau GmbH

The STA 509 Jupiter® Series offers various accessories and extensions for optimal customization to meet your needs.

For cooling the furnace, options include cooling back to room temperature using compressed air or achieving temperatures as low as -150 °C with liquid nitrogen cooling. Cost-efficient intracoolers provide an alternative to liquid nitrogen cooling.

Explore the range of crucibles designed for materials science applications. Crafted from high-quality materials such as highly sintered ceramics, refined metals, and pure graphite, the crucibles ensure reliable measurements for challenging substances like high-melting alloys, molten salts, and refractory materials. Perforated crucibles and net-shaped sample holders enhance the interaction between reactive gases and the sample, optimizing analysis conditions.

- Automatic Piercing Device

An optional automatic piercing device, attached to the gripper, is available. This device is designed to open the lids of aluminum crucibles shortly before the measurement starts, facilitating seamless sample preparation and analysis.

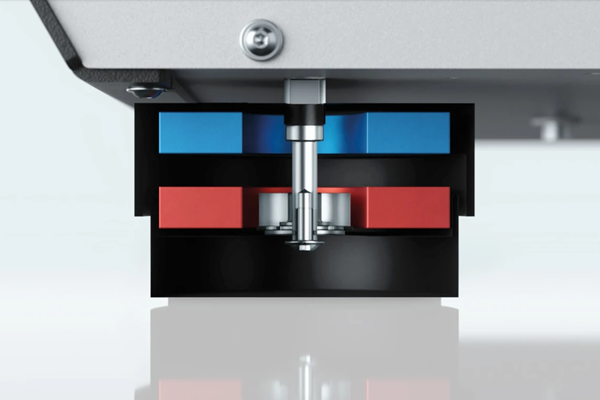

Image Credit: NETZSCH-Gerätebau GmbH

The standard feet on the 509 Jupiter® series can be optionally replaced with a patented magnetic levitation system. This system effectively shields the instrument from external disturbances such as vibrations, ensuring reliable results are unaffected by environmental fluctuations.

Image Credit: NETZSCH-Gerätebau GmbH

Discover the versatility of materials science through our extensive selection of crucibles. Crafted from premium materials like highly sintered ceramics, refined metals, and pure graphite, the crucibles guarantee reliability in measuring challenging materials, such as high-melting alloys, molten salts, refractory materials, and beyond.

Image Credit: NETZSCH-Gerätebau GmbH

Proven Excellence in Service

NETZSCH Analyzing & Testing provides a wide range of services worldwide to guarantee the longevity and best possible performance of thermoanalytical equipment. These services, which have a history of excellence, increase the efficiency of the devices, prolong their life, and reduce downtime.

With specialized solutions supported by years of industry experience and innovation, users can unleash the full potential of their equipment.

Image Credit: NETZSCH-Gerätebau GmbH

Software

STA 509 Jupiter® with Proteus® - The Powerful Analytical Software

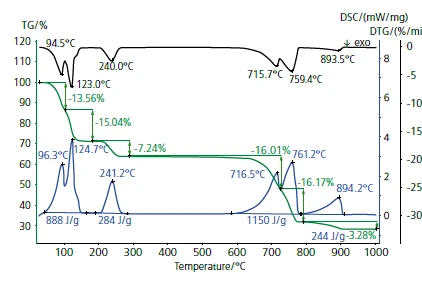

AutoEvaluation – Fast and Objective Results Right After a Measurement

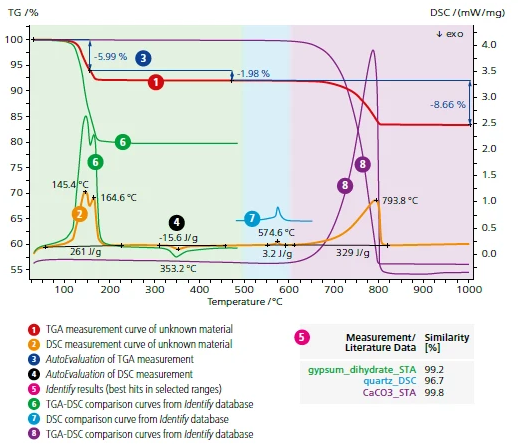

AutoEvaluation is the industry's first self-operating evaluation system for TGA and DSC analyses. It assesses notable mass shifts and endo- or exothermic reactions automatically without the need for human input, produces DTG curves, and pinpoints peak temperatures. It enables the customization of detection settings and displayed results and offers real-time post-measurement display of evaluated curves.

Both inexperienced and seasoned users benefit from AutoEvaluation's impartiality and time efficiency. The thermal analysis of CuSO4·5H2O, which demonstrates a water release below 300 °C, is one example of an application.

Image Credit: NETZSCH-Gerätebau GmbH

Identify – The Database for Material Identification and Quality Control

Identify is a special software tool for material identification and classification in thermal analysis. More than 1,300 entries from the application areas of polymers, organics, pharmaceuticals, food, cosmetics, inorganics, ceramics, metals, and alloys are included in the NETZSCH libraries. Supported signal types are DSC, DSCcp, TGA, STA, DIL/TMA, TGA-c-DTA®, and DMA.

Libraries containing an infinite quantity of user-provided data allow users to increase the size of the database. This expanding set of measurement conditions and database entries can also be a great resource for planning upcoming experiments.

Image Credit: NETZSCH-Gerätebau GmbH

The fact that Identify can even combine two measurement types—like TGA and DSC or c-DTA®—simultaneously during identification is especially useful. The analysis using Identify in the temperature range below 500 °C, as demonstrated in the example above, shows that the TGA-DSC results are very similar to those found in the database for gypsum (dihydrate, CaSO₄·2H₂O). The structural α→β transition of quartz is responsible for the DSC peak detected at 575 °C.

This peak is also in the most similar database curve within that temperature range. The database search yielded the best result above 600 °C, which measures calcium carbonate degradation. In conclusion, the analysis revealed that the composition of the unidentified material is calcium carbonate, quartz, and gypsum.

This Instrument is LabV®️-Primed

LabV®TM obtains the information from an analytical tool: All measurement data is automatically imported into the LabV®TM software, a centralized, secure database solution. This makes it possible for users to search and view the data in LabV®. Users can now access the data from any location. Users also have the option to create reports.

Additional Software Capabilities

- Beflat – An Intelligent Way to Save Time

The BeFlat® software feature records temperature and other measurement influences, such as heating rate, purge gases, and gas flow rates. It provides TGA and DSC corrections tailored to the selected measurement conditions, eliminating the need for a separate blank value determination or correction measurement.

- Proteus Search Engine – Smart Data Management

Direct access and sorting by specific criteria are crucial when working with measurement and evaluation data across various materials and setups. The Proteus® Search Engine synchronizes with selected directories and swiftly filters the data.

Users can preview measurement curves or analysis states with a single click and create customized searches like "MyCeramics," effortlessly switching between saved searches. This capability makes Proteus® Search Engine a highly potent tool for data management in research and analysis.

Advantages of Proteus® Search Engine

- Directly access and sort data by criteria

- Efficient data management

- Quick previews of measurement and analysis without needing to open files, enhancing efficiency

- Searching by instrument name, method, operator, file and signal type, date, measurement conditions, or evaluated effects allows for precise data retrieval and organization.

Each operator can effortlessly create personalized report templates in the Proteus® software, incorporating company logos, tables, description fields, and plots. The software includes several pre-existing report templates as examples. Results from Identify searches can also be seamlessly integrated into these reports.

The software is designed to handle experimental curves with complexities such as overlapping mass-loss steps, DSC peaks, or MS/FT-IR peaks. It assists in separating these effects, presenting experimental data as a sum of individual peaks and enabling separate analysis of each peak.

The specific heat capacity (cp(T)) from the DSC signal can be calculated using ratio and stepwise methods compliant with standards like ASTM E1269, DIN 51007, or DIN 11357-4. Additionally, cp(T) can be derived directly and automatically from the DSC heat flow following DIN 51007 standards. Results for cp(T) can be displayed alongside uncertainty margin curves, providing comprehensive data for thermal analysis.

- Kinetics NEO – Process Optimization by Prediction

Kinetics Neo software from NETZSCH creates kinetic models for chemical reactions and physical processes using measurements under varying temperature conditions.

It accurately models even multi-step processes by calculating kinetic parameters such as activation energy, pre-exponential factor, and reaction order. This enables the prediction of chemical system behavior under user-defined conditions, facilitating process optimization and analysis.

- Proteus Protect – Compatibility with CFR 21 Part 11

Proteus® Protect is an option available for all STA devices, including coupling, and it meets the technical requirements specified in 21 CFR Part 11.

Source: NETZSCH-Gerätebau GmbH

| |

Classic |

Select |

Supreme |

| AutoEvaluation |

✅ |

✅ |

✅ |

| TGA-BeFlat®* (TGA&DSC) |

✅ |

✅ |

✅ |

| AutoCalibration |

✅ |

✅ |

✅ |

| c-DTA® |

✅ |

✅ |

✅ |

| OIT |

✅ |

✅ |

✅ |

| Report Generator |

✅ |

✅ |

✅ |

| Eco Mode |

✅ |

✅ |

✅ |

| Identify |

|

|

✅ |

| Proteus® Search Engine |

|

|

✅ |

| Peak Seperation |

|

|

✅ |

| Specific Heat Capacity (cp) |

|

|

✅ |

| Temperaturemodulated TGA (TM-TGA) |

|

|

✅ |

| SuperRes |

|

|

✅ |

| TauR |

|

|

✅ |

| Purity |

|

|

|

| LabV® |

|

|

|

| Proteus® Protect (CFR21 part 11) |

|

|

|

| Kinetics NEO |

|

|

|

| Thermica NEO** |

|

|

|

| EGA support |

|

|

|

✅ = Included

= Optional

= Optional

⛔️= Not available

* included when MFC is selected

** requires Kinetics Neo