PI Ceramic has achieved a first breakthrough in the manufacturing of lead-free piezoceramic components and now invites customers to joint development projects. In particular, the bismuth sodium titanate (BNT) and potassium sodium niobate (KNN) material systems now provide similar performance to the classic lead (plumbum) zirconate titanate (PZT) system in some applications.

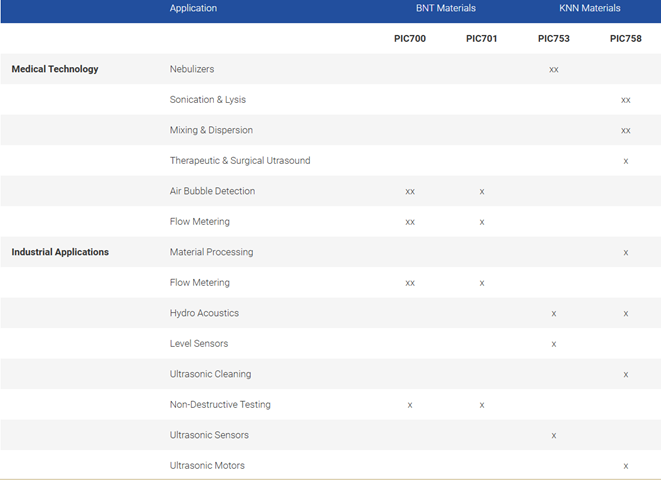

This table provides an overview of possible applications for lead-free piezoceramics. For the applications marked with xx, positive test results have already been obtained. Image Credit: PI Ceramic

This table provides an overview of possible applications for lead-free piezoceramics. For the applications marked with xx, positive test results have already been obtained. Image Credit: PI Ceramic

The first positive results from the use of lead-free piezoceramics are available for applications with dynamic control. In micropumps, ultrasonic nebulizers, and power ultrasonic transducers, as well as in various sensors, the BNT and KNN material systems can serve as an alternative to lead-containing materials.

For both material systems, PI Ceramic offers materials with different levels of technological maturity for customized developments. There are various challenges, as lead-free materials behave differently compared to PZT ceramics. For example, the voltage and current or the geometric dimensions of the components usually need to be adjusted to achieve the desired application-specific results. For each application, long-term stability and response to environmental conditions (temperature/humidity) must also be assessed.

Dr. Patrick Pertsch, Managing Director of PI Ceramic, emphasizes: “For several years, we have been conducting research into the possible applications of the BNT and KNN materials systems. We are now pleased to offer our customers the development of lead-free components for their systems.”

Background

To reduce the use of environmentally hazardous substances and to avoid potential environmental pollution, the European Commission is promoting the use of lead-free materials with the RoHS (Restriction of Hazardous Substances) Directive. Many technologies are affected, including the manufacture and use of piezoceramics. Although the PZT material system is still considered the gold standard for performance and reliability in piezoelectric applications, the demand for alternatives is increasing, particularly in medical applications.