Lithium-ion battery production requires a tightly controlled environment, strict safety protocols, and comprehensive quality assurance at every stage of manufacturing.

Image Credit: Cubic Sensor and Instrument Co. Ltd

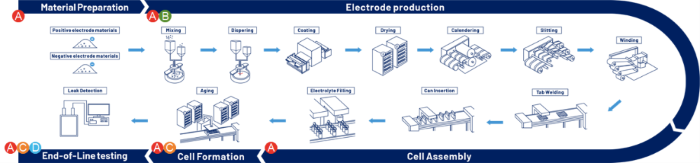

The process is typically divided into five main steps:

- Step 1: Material Preparation

- Step 2: Electrode Manufacturing

- Step 3: Cell Assembly

- Step 4: Formation & Aging

- Step 5: Final Testing

At each stage, the use of environmental air monitoring, safety monitoring, and process quality monitoring systems ensures product consistency, safety, operational efficiency, and compliance with regulatory standards.

Lithium Battery Production Monitoring Demands at Each Phase

Image Credit: Cubic Sensor and Instrument Co. Ltd

Stringent monitoring and control are required at all stages of lithium-ion battery manufacturing in cleanrooms to ensure cleanroom compliance, product quality, safety, and operational efficiency.

In the material preparation stage, airborne particles and humidity have a significant impact on material reactivity and dispersion. When handling high-nickel cathodes or silicon-based anodes, trace moisture can cause oxidation or agglomeration, affecting product quality.

Monitoring trace moisture levels and maintaining stable humidity are, therefore, essential to avoid material instability and ensure optimal processing conditions.

N-Methyl-2-pyrrolidone (NMP) is a common solvent used in slurry processing during electrode manufacturing. However, NMP is highly volatile and flammable, creating serious safety risks. Continuous monitoring of NMP vapor concentration is necessary to prevent fire or toxicity hazards.

Electrolyte leakage is a major concern during the cell assembly stage, particularly when the electrolyte is corrosive and volatile. Any leakage can lead to fire, corrosion, or other safety hazards, so implementing leak detection systems is critical to identifying and addressing risks promptly.

Maintaining a clean environment during assembly is also important to prevent contamination and achieve the precision needed for high-quality output. Assembly carries additional risks, such as micro short circuits or localized overheating, which can lead to thermal runaway.

Monitoring gases like smoke, carbon monoxide, and vaporized electrolyte is necessary to detect early signs of thermal instability and enable timely intervention.

The formation and aging stages are among the highest-risk phases of battery manufacturing due to heat, gas expansion, and structural stress that occur during initial charging.

Monitoring gas emissions (such as smoke, carbon monoxide, and electrolyte vapors) is essential for identifying abnormal behavior and preventing accidents.

Early detection of gas release can serve as a warning sign of thermal runaway, allowing for quick response and risk mitigation. Robust fire suppression and hazard monitoring systems should be employed during these stages to reduce the risk of accidents.

During final testing, batteries undergo thorough inspection to verify quality and safety. Leak detection remains a critical part of this stage, confirming that no electrolyte leakage compromises battery integrity.

Thermal runaway monitoring can support root cause analysis of abnormal cells, improve traceability, and support ongoing process improvement.

Cubic Li-Battery Manufacturing Process Sensing Solutions

Cubic, a leading manufacturer of gas sensors and analyzers, has applied its established sensing technologies to support lithium battery manufacturing. These technologies include light scattering, NDIR, TDLAS, MEMS MOX, MEMS thermal conductivity, and Laser Raman.

Using this foundation, Cubic has developed a comprehensive product portfolio that addresses three key monitoring areas: environmental air quality, process and quality control, and manufacturing safety.

Environmental Air Quality Monitoring

Environmental air quality monitoring is critical in lithium-ion battery manufacturing to maintain material integrity, worker safety, and process precision.

Controlling airborne factors (such as particulates, humidity, and temperature) prevents contamination, chemical instability, and safety hazards.

Air quality monitoring also ensures cleanroom compliance with regulatory standards, supports high-quality production, and enhances operational safety throughout the manufacturing process.

Cubic has applied its established light scattering technology to develop a series of optical particle counters for use in cleanroom environments. These counters monitor the concentration of suspended particles of various sizes in the air per unit volume in real time.

Cubic's online optical particle counters (OPC-6303DS, OPC-6510DS, and OPC-6511DS) feature a proprietary dust source intelligent identification module that delivers high particle identification efficiency and detection accuracy.

A built-in ultrasonic gas flow sensor allows for 28.3 L of constant current sampling with strong long-term data stability. Each counter is equipped with a 3.5-inch touch screen to display particle size data and alert prompts.

When particle levels reach a predefined threshold, the built-in buzzer triggers an alarm, which is particularly useful in panel manufacturing cleanrooms.

Low-noise turbine fan sampling supports continuous, stable monitoring with a long service life.

These devices are designed to meet the requirements of ISO 14644-1:2015, the revised GMP standard, JF1190-2008, and GB/T6167-2007, making them suitable for use in cleanrooms classified as Class 100, Class 1,000, Class 10,000, and Class 100,000.

Cubic also used TDLAS technology to create a trace moisture sensor for humidity monitoring, as well as NDIR and MEMS MOX technologies for HVAC thermostats to control indoor air quality.

These systems enable real-time monitoring of CO2, VOCs, and PM2.5 levels, allowing cleanroom HVAC systems to dynamically adjust airflow, optimize ventilation, and maintain particle levels.

Process and Quality Monitoring

Monitoring electrolyte leakage and thermal runaway is essential during lithium battery production. Electrolytes typically contain flammable and toxic organic solvents along with lithium salts.

If leaked, these substances pose risks to personnel health and equipment, and may lead to serious incidents such as fires or explosions. Thermal runaway, often triggered by minor anomalies, can also have catastrophic consequences if not properly monitored.

Implementing process and quality monitoring for both electrolyte leakage and thermal runaway can effectively reduce accident risk, protect personnel and the environment, and improve production yield while complying with increasingly strict safety regulations.

Cubic has developed a thermal runaway early warning system by integrating multiple sensing technologies (including NDIR infrared, MEMS MOX, thermal conductivity, and laser scattering) on its gas sensor technology platform.

These sensors monitor key indicators released in the early stages of thermal runaway, such as CO2, H2, CO, temperature, pressure, and aerosol particles.

Data from the sensors is transmitted via CAN bus to the Battery Management System (BMS), providing a reliable and timely alert mechanism for thermal runaway prevention.

Cubic has also applied its established Laser Raman technology to support thermal runaway analysis in lithium-ion batteries.

As a highly sensitive molecular characterization technique, Laser Raman allows real-time observation of structural changes in electrode materials, electrolyte decomposition, and interfacial reactions under elevated temperatures or fault conditions.

In the early stages of thermal runaway, Raman spectroscopy can detect CO2, CO, and changes in the solid electrolyte interphase (SEI), providing valuable insight into the chemical processes that lead to instability.

This supports the development of safer battery materials and improved thermal management strategies.

To further ensure safety during the lithium battery manufacturing process, electrolyte leakage must be effectively managed.

Cubic’s self-developed handheld electrolyte leakage detector, AM4210, features a TFT LCD display and can both locate leakage points and quantitatively analyze leakage concentration in the current environment.

Manufacturing Safety Monitoring

Safety monitoring is a top priority throughout lithium battery manufacturing, including electrode coating, cell assembly, and electrolyte filling. One of the key concerns is the use of NMP (N-Methyl-2-pyrrolidone), a volatile and toxic solvent commonly used during slurry preparation and coating.

Undetected NMP vapor leaks pose serious health risks to workers and increase the likelihood of fire and regulatory non-compliance.

Cubic’s NMP Leak Detector offers high sensitivity and fast response to low concentrations of NMP gas in real time, enabling early warning and effective ventilation control to ensure worker safety and maintain production continuity.

In powder processing and battery formation areas, Cubic’s explosion-proof Optical Particle Counter supports reliable airborne particle monitoring, even in flammable environments.

With ATEX-certified housing and anti-static optics, the device provides accurate PM concentration measurements in hazardous zones, helping to prevent dust explosions and maintain cleanroom quality standards.

Together, these sensing solutions form a vital part of an integrated safety monitoring system, supporting lithium battery production with precision and reliability.

Process monitoring is also becoming increasingly important in the lithium battery industry. The performance, lifespan, and safety of lithium batteries depend on accurate monitoring throughout the entire production process. From raw material selection to final battery assembly, each step requires strict process control to avoid defects and potential safety risks.

Cubic’s comprehensive monitoring solutions enhance production efficiency and product quality, significantly improve safety, and support sustainable development across the lithium battery industry.

This information has been sourced, reviewed and adapted from materials provided by Cubic Sensor and Instrument Co. Ltd.

For more information on this source, please visit Cubic Sensor and Instrument Co. Ltd.