The measurement of gels and film properties is of widespread interest in the manufacture of food, packaging, pharmaceutical, medical and cosmetic products.

Gel strength, elasticity and rupture force are important in the development of such products as gel capsules, contact lenses and edible preserves whilst gel-forming properties are useful in the manufacture of wound dressings, jelly lubricants, and bacterial growth media. The strength of gels can also be utilised in products such as toothpaste, creams and pastilles to modify the consistency of the required end product.

Films (including edible and biodegradable films) meanwhile represent an area of rapid development as they have the potential to reduce and simplify packaging materials required for the protection of many consumer products or carry active additives or functional ingredients such as antioxidants, antimicrobials, flavourings or pigments.

Whilst gels and films are increasingly finding a wider range of applications, manufacturers are in need of a means of assessing all of the potential parameter effects on, in particular, their mechanical properties. The mechanical properties of a material may be assessed by many methods, including tensile, puncture, and compression techniques all of which can be provided in varying manners by a Texture Analyser.

Much of the instrumentation and tests are based upon non-edible plastic packaging materials and as such are geared towards standard testing methods (ASTM or ISO). The limitation of applying these standards is the defined sample preparation which may be difficult (if not impossible) to conform with when faced with edible films for certain applications.

The following set of tests highlights not only the standard method approach for film and gel testing but, more importantly, gives alternative testing options that accommodate the testing of gels and films of varying types and dimensions and the range of additional material characteristics which can be measured using texture analysis.

Typical Texture Analysis tests for gels and film products

How to measure gel strength

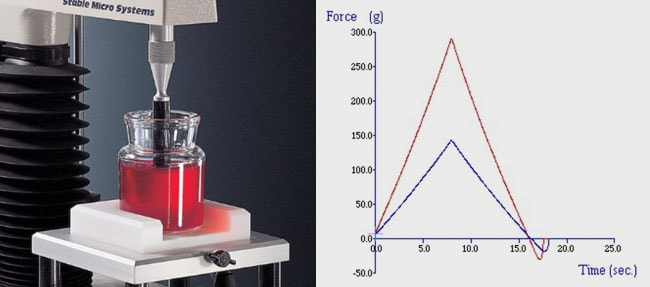

Using texture analysis, gels can be assessed by measuring their mechanical resistance to stress. In a simple gel strength measurement, using, for example, a TA.XTplus Texture Analyser, a cylinder probe typically of 0.5 inch diameter, is lowered into the gel system at a fixed speed. The gel strength is reported as the peak force required to reach a chosen distance usually before permanent deformation. However, by penetrating further into the gel the rupture force and a measure of the gel’s elasticity/brittleness can also be obtained. Standard probes, such as those required for ISO, AOAC, GMIA standards tests, are also available for the assessment of gel bloom or rupture.

A gel penetration test using a TA.XTplus texture analyser with its resulting typical graphs. Image Credit: Stable Micro Systems

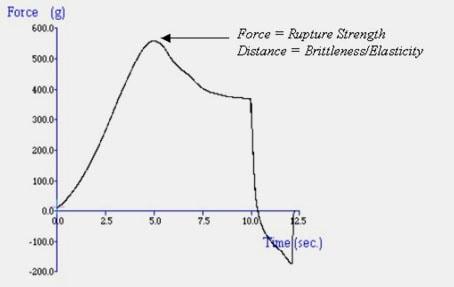

A gel penetration test using a TA.XTplus texture analyser continuing to the point of rupture. Image Credit: Stable Micro Systems

For self-supporting gels and a more fundamental test approach, the elastic moduli can be determined by compressing cylindrical shape gels with a larger surface area cylinder probe. Elastic moduli are determined from the initial parts of the stress-strain curves.

Cylindrical gel sample tested to determine elastic moduli. Image Credit: Stable Micro Systems

Other typical measurements that can be performed on gels include adhesiveness, consistency and mucoadhesion.

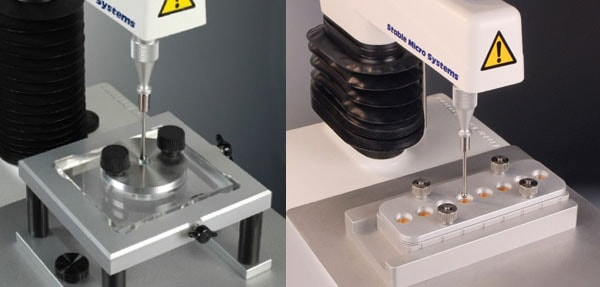

Rigs showing means of measuring adhesiveness, consistency and mucoadhesion. Image Credit: Stable Micro Systems

How to measure film strength and resilience

Film strength measured by uniaxial testing. Image Credit: Stable Micro Systems

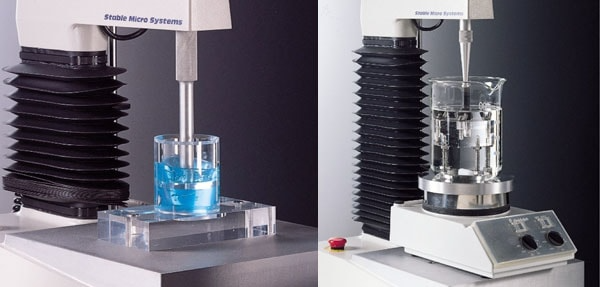

For food packaging, important characteristics include mechanical properties such as tensile strength, flexibility and elongation at break (%E). Generally plasticisers are added to polymers to improve the overall flexibility and extensibility of the resulting film or coating and the effect on strength, pliability and flexibility can be measured using tensile testing techniques. Further addition of plasticising agents will result in rubbery, sticky films thus it is necessary to optimise the amount used in a formulation to attain the desired film properties.

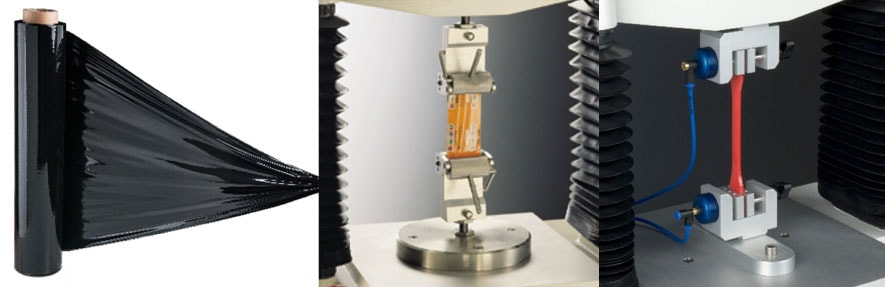

Subjecting films to tensile stress is widely used as a fast and accurate method of defining whether the material is strong and flexible enough for its required application. Attached to the base plate and the cross head of the Texture Analyser, tensile grips firmly hold the film sample from both ends. A test is then performed at a predetermined speed and the results, such as tensile strength, work of failure, elastic modulus and extension, or elongation to break, are calculated from load-extension curves. Pneumatic grips are often a preferred means of holding a sample for tensile testing because the gripping pressure can be controlled precisely as it is not affected by the deformation of the sample.

Although tensile or pneumatic grips are traditionally used to assess the tensile properties of polymeric films, the reproducibility of results can be compromised if the pressure is unevenly distributed across the sample’s surface area. By comparison, the Film Support Rig (or Indexable Film Support Rig) can hold small sections of film in a drum configuration, which means the pressure is evenly distributed around the circumference of the sample. A spherical probe which is driven down onto the sample film thereby measures biaxial strength. The force required to burst the film is recorded and is referred to as the burst strength or break point of the film.

Film properties measured by biaxial testing using a Film Support Rig and Indexable Film Support Rig. Image Credit: Stable Micro Systems

The rig can also be used to measure resilience and relaxation. By comparing the work of compression and withdrawal when depressing the film surface a certain distance a measure of resilience can be calculated. Similarly, a coefficient of relaxation can be analysed by holding a probe on the surface for a predefined length of time and calculated from a force-time curve. The ability to calculate the relaxation and resilience of films can be useful data for manufacturers to assess how well a film may withstand being handled in practical situations.

For a full summary of typical texture analysis tests that can be performed on gel and film products:

Gel & Film Texture Measurement & Analysis