Vacuum Sources for Rotary Evaporators

A rotary evaporator offers a great number of benefits, which make this technology the most vital tool within solvent evaporation on a laboratory and pilot scale.

Gentle and efficient evaporation, which is a result of, among other things, the consistent distribution of the substance mixture on the inner wall of the evaporator flask, takes place with a low supply of heat thanks to a vacuum.

It is the main factor supporting this proven technology. This document spotlights the correct vacuum source for the desired application.

What is the Task of Vacuum in the Evaporation Process?

Vacuum is the key component in the evaporation process. While rotation and heating bath typically remain constant, the vacuum is the variable used to reach the desired boiling point. Compared to temperature, the vacuum can be rapidly changed and does not have a negative impact on thermolabile substances.

In spite of this critical role in the evaporation process, the vacuum pump is generally viewed as an incidental accessory to which only slight attention is paid, although the pump can also be a key factor for several applications. For instance, when evaporating high boiling solvents such as DMSO.

If an inappropriate pump with low power is selected for this task, evaporation becomes difficult or impossible.

What Technologies are There?

In terms of various technologies, but also electricity consumption, control accuracy and other factors such as noise level and maintenance intensity play a crucial role in performance. The most frequently used technologies include:

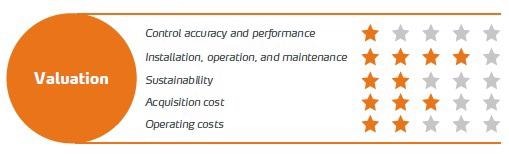

A house vacuum connection: often installed at universities and large research centers. An appropriately dimensioned vacuum pump is utilized as a central source for vacuum supply in an entire working group, floor or even building complex.

The rotary evaporator is connected to this vacuum source – which is typically non-regulated – via glassware connections. The control of the vacuum is generally maintained via a valve controlled by the rotary evaporator or a separate controller.

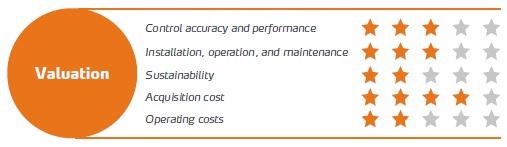

Non-regulated vacuum pump: is an alternative frequently and generally used for one to three rotary evaporators. These vacuum pumps are typically cost-effective and run in line with the maximum performance required by the customer.

They also produce a vacuum that is initially uncontrolled, which then, analogous to the house vacuum, regulates the negative pressure within the glassware of the rotary evaporator via an interposed vacuum valve.

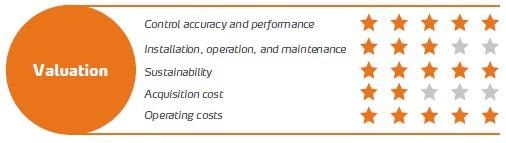

A speed-controlled vacuum pump: this is radically different from the other alternatives. The fundamental principle of this pump is to offer flexible adjustment relative to the speed to the signal of the rotary evaporator or the control unit of the pump with on demand functionality.

Due to the extremely precise and dynamic regulation of the speed, these pumps reach a desired boiling point with great accuracy. For instance, if a set value of 160 mbar is set, the pump will gradually reduce the speed to 200 mbar to reach precise regulation.

As soon as the pump has achieved the setpoint, it switches to a pause mode, only becoming active once the leak in the overall system leads to the setpoint or a set hysteresis being exceeded.

In this example, the pump is momentarily awakened from standby mode and the speed is typically only increased for one to two seconds in order to reestablish the system vacuum setpoint.

A Consideration of the Factors: Process Behavior, Operation, Sustainability and Costs for the Present Technologies

A house vacuum connection offers several user advantages. One example is in the maintenance of the pump. This is often a task limited to a large system due to it being one of central technology. However, many consumers also rely on the functionality of the vacuum source.

If a scenario in which a defect occurs arises, there can be significant efficiency losses in the daily workflow and possible stoppages and thus considerable delays in research.

The benefits are that the central supply typically has a small footprint in the laboratory itself and there is a limited increase in noise levels caused by the decentralized pump.

Total electricity consumption at a well-calculated capacity utilization is lower than that of many non-regulated pumps but is still considerably greater than that of demand-oriented speed-controlled systems.

One of the main disadvantages of a central supply is fluctuations in the system’s power, which can transpire due to a large number of consumers or have a negative influence on the suction power and ultimate vacuum that can be achieved.

The latter tends to be lower than a solution with one vacuum pump per evaporator. The accuracy of the process also suffers from the fact that a valve switch is needed in order to control the fixed vacuum value of the house vacuum to the requisite setpoint by venting.

To summarize, a house vacuum is not the best solution as it is imprecise for the process of evaporation. While it offers some benefits in terms of operation, costs and sustainability, it is of average performability.

Image Credit: Heidolph North America

Non-regulated vacuum pump: this is typically a single pump that can be utilized for numerous applications that necessitate a vacuum. On the process side, these pumps, with their advanced technology, offer a dependable vacuum supply for the rotary evaporator but are susceptible to the same obstacles as the house vacuum.

Here, too, the compensation of the pump's fixed vacuum value and the ambient pressure for the desired vacuum value is balanced out via a vacuum valve.

This method of functionality leads to an average precise vacuum control and a certain hysteresis in the evaporation process. Sustainability and consequentially the permanent costs are probably the major drawbacks of this technology.

The fact that the pumps continuously function at full power – even if the target vacuum in the rotary evaporator has been reached – leads to an increase in power consumption, which would be superfluous with the rotary evaporator’s increasing tightness.

Moreover, it should be considered that maintenance intervals and the replacement of wear parts very much depend on the pump’s actual operating performance and are therefore required more frequently here. This pump is the best alternative when typically looking for a flexible system that is in infrequent use.

Image Credit: Heidolph North America

A speed-controlled vacuum pump: the most technically advanced solution for rotary evaporation. The main benefit here lies in the gentle regulation of the vacuum and the accurate, overshoot and hysteresis-free control to a set vacuum.

Due to the fact that the target vacuum value maintains the value set with extreme precision and gentle readjustment, this system impresses with optimal vacuum control as well as considerably lower or almost no hysteresis throughout the evaporation process.

This, in turn, limits the danger of delays in boiling, foaming media and enables purer material separation. A high quality pump also has the option to intentionally reduce the pump performance.

As a result, a system can be evacuated much more gently in good time, which in turn has benefits relative to avoiding foam and boiling pressure.

Another advantage is that automatic evaporation programs such as Heidolph's AUTOaccurate, can achieve their potential and determine boiling points more reliably thanks to the exceptional vacuum supply.

Additionally, the fact that the pump actively functions only when necessary reduces the energy consumption to up to 90% - especially in combination with low leakage, sealed rotary evaporators. Similarly, positive effects are accomplished relative to maintenance intervals and the need for wearing parts.

However, the comparatively high price of the pump may be disadvantageous to some and the limitation is that the systems can typically only be used for a rotary evaporator.

Although these pumps do not necessitate a vacuum valve and generally cost several hundred euros, they counter the replacement of the wearing parts, which can extend to up to 100 euros as well as provide annual savings in terms of electricity costs, this system pays for itself over several years.

In addition, it should be considered that these advantages develop once the rotary evaporator is in regular use.

Image Credit: Heidolph North America

This information has been sourced, reviewed and adapted from materials provided by Heidolph North America.

For more information on this source, please visit Heidolph North America.