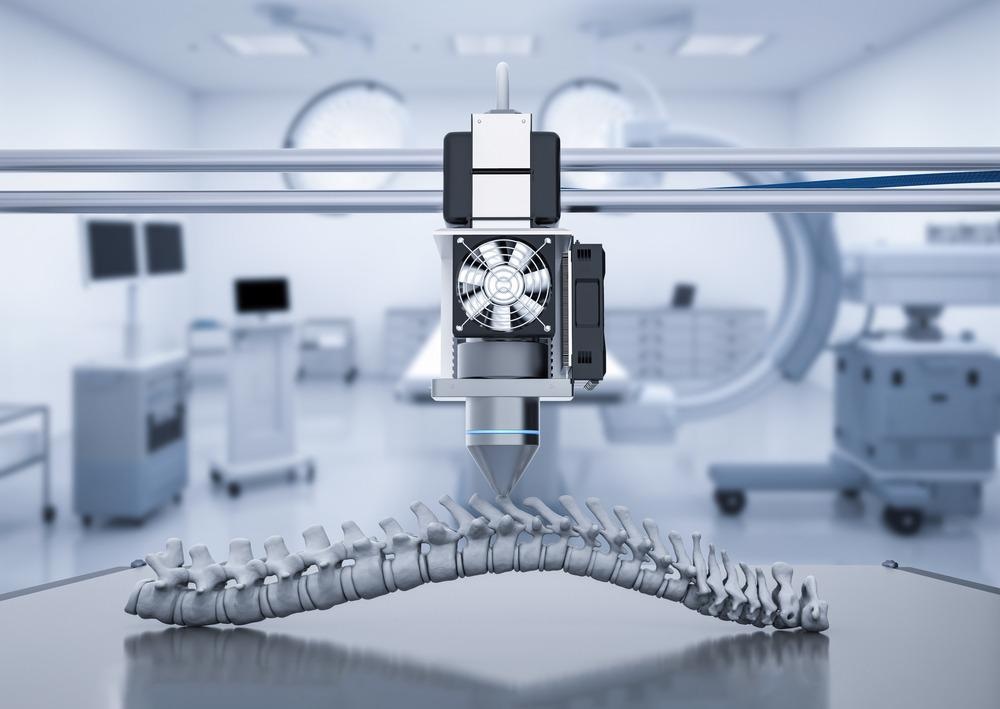

Biomaterials are synthetic or natural materials that interact with biological systems. These materials are predominantly used in medicine and dentistry, where they come into contact with living tissues. 3D printing is a rapidly emerging field of tissue engineering and regenerative medicine that allows the development of patient-specific orthoses, scaffolds, and prostheses with improved structural complexity and design flexibility.

Image Credit: Phonlamai Photo/Shutterstock.com

The selection of biomaterials for 3D printing is based on the application of the end product. For example, biomaterials such as ceramics, metals, hard polymers, and composites are commonly used in dental or orthopedic applications due to their high mechanical stiffness and extended biodegradation rates. However, biomaterials such as soft polymeric hydrogels that are highly flexible with rapid degradation rates are selected for dermal or other visceral organ applications.

Role of Polymeric Biomaterials in Medicine

Polymeric biomaterials, especially, have had an immense impact on the advancement in health care technology. These materials interact with the biological system and are associated with the regeneration or repair of damaged tissues. Additionally, polymeric biomaterials are used to treat any type of organ tissue or dysfunctions in the human body.

Polymers help to develop a versatile group of biomaterials with applications in tissue engineering and regenerative medicine. One of the essential properties of a polymeric biomaterial is its flexibility in tailoring its mechanical, physical, and chemical properties. The relevant chemical modifications of the functional groups aid in improving the regeneration potential of any organ tissue.

Bioresorbable polymers can be used as a bioactive scaffold for tissue regeneration as well as for drug delivery. The mechanism behind the degradation of these polymers is bulk erosion and hydrolysis of ester bonds. Scientists can modify the rate of degradation by changing the molecular weight, crystallinity, and copolymer ratio.

More examples of commonly used polymeric biomaterials that are used in medicine are silicone rubber, polyethylene (PE), acrylic resins, polyurethanes, and polymethylmethacrylate (PMMA).

A Novel 3-D Printing Technique

Previously, researchers faced difficulties printing soft materials because if they were not supported, they tended to sag and lose their shape. Researchers at the University of Birmingham have developed a new, improved technique that involves 3D printing of soft materials such as gels and collagens, which can be used in artificial medical implants. The research was published in Advanced Functional Materials on September 27th 2019.

Their technique is called Suspended Layer Additive Manufacturing (SLAM), which uses a polymer-based hydrogel modified to be a self-healing gel. In this method, liquids or gels can be directly applied to the medium and are methodically built up in layers to produce a 3D shape. One of the limitations of the existing technique, namely, Freeform Reversible Embedding of Suspended Hydrogels (FRESH), is the development of frictions within the gel medium that can distort the printing.

Professor Liam Grover of the University of Birmingham led the research team involved in creating the novel 3D printing technique. He describes how the newly developed gel particles could be sheared or twisted to separate them, yet a connection between particles is still retained. This interaction is responsible for the self-healing effect. Here, the gel can support the printed material, enabling the development of objects with precise details without facing any disadvantages like leaking or sagging.

The researchers are optimistic that SLAM has great potential for creating replacement biomaterials such as heart valves or blood vessels. Additionally, it can also produce biocompatible plugs for the treatment of bone and cartilage damage. A significant advantage of SLAM is that it can create objects comprising two or more different materials, which enable the development of complex tissue types.

New Biomaterial-4Degra™

Even though many biomaterials are being rapidly manufactured, researchers believe the best biomaterial is yet to be developed. An ideal biomaterial for use in regenerative medicine should be biocompatible, non-toxic, biodegradable, uphold tissue regeneration, and have superior handling properties in a clinical environment.

Recently, a novel polymeric biomaterial has been developed by 4D Biomaterials, called 4Degra™ that possesses all the above-stated properties of an ideal biomaterial. 4D Biomaterials stated that this newly developed polymeric 3D printing resin-ink is a polycarbonate-urethane-based polymer that undergoes non-toxic biodegradation; its properties can be tailored to suit wide-ranging tissue regeneration applications.

4D Biomaterials recently announced the development of this patent ranged biomaterial at the United Kingdom’s leading Med-Tech trade event.

One of the main advantages of these 3D printable resin-inks is that they will enable the development of medical implants with optimal fitting by obtaining the exact shape and dimensions required for a particular patient.

To evaluate the properties of 4Degra™, 4D Biomaterials conducted an in-depth in-vitro and in-vivo analysis, which provided robust evidence associated with biocompatibility and regeneration properties. 4D Biomaterials is optimistic that this product would immensely improve healthcare research and benefit patients and other multiple stakeholders in the health sector.

The Road Ahead for 4D Biomaterials

4D Biomaterials has collaborated with medical device manufacturers and 3D printing companies to create unique medical devices using this polymeric biomaterial. At present, they are involved in developing target product concepts for a range of devices, including implantable micro-devices and tibia fracture repair devices.

The company has also obtained funding support from Innovate UK and is developing new medical device concepts for its own brand. One of the most advanced medical devices designed by 4D Biomaterials is the 4D Conserva breast-conserving lumpectomy device.

4D Biomaterials has collaborated with medical device manufacturers and 3D printing companies to create unique medical devices using this polymeric biomaterial. At present, they are involved in developing target product concepts for a range of devices, including implantable micro-devices and tibia fracture repair devices.

The company has also obtained funding support from Innovate UK and is developing new medical device concepts for its own brand. One of the most advanced medical devices designed by 4D Biomaterials is the 4D Conserva breast-conserving lumpectomy device. 4D Biomaterials aspires for future collaborations with associated companies to develop more innovative medical devices.

References and Further Reading

Pugliese, R., Beltrami, B., Regondi, S. and Lunetta, C., (2021) Polymeric biomaterials for 3D printing in medicine: An overview. Annals of 3D Printed Medicine, 2, p.100011. Available at: https://doi.org/10.1016/j.stlm.2021.100011 [Accessed August 2021]

4D Biomaterials. (2021) Our technology - 4D Biomaterials. [online] Available at: https://4dbiomaterials.co.uk/our-technology/

University of Birmingham. (2019) New 3D printing technique for biomaterials. [online] Available at: https://www.birmingham.ac.uk/news/latest/2019/10/new-3d-printing-technique-for-biomaterials.aspx [Accessed August 2021]

Senior, J., Cooke, M., Grover, L. and Smith, A., (2019) Fabrication of Complex Hydrogel Structures Using Suspended Layer Additive Manufacturing (SLAM). Advanced Functional Materials, 29(49), p.1904845. Available at: https://doi.org/10.1002/adfm.201904845 [Accessed August 2021]

Shanmugam, K. and Sahadevan, R., (2018) Bioceramics—An introductory overview. Fundamental Biomaterials: Ceramics, pp.1-46. Available at: https://doi.org/10.1016/B978-0-08-102203-0.00001-9 [Accessed August 2021]

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.