The concept of metamaterials was first introduced in 1967 by Victor Vesalago, and ever since, the field has undergone significant expansion and evolution.

Image Credit: Alexander Tolstykh/Shutterstock.com

Metamaterials are materials that undergo modification so that they possess properties that don’t naturally occur. This manufacturing process enables them to have high specificity for a particular function. Here, this unique class of material will be outlined, discussing a fascinating discovery by scientists from North Carolina University.

Current Use of Metamaterials

Metamaterials are fabricated using composite materials like plastics or metals and can manipulate electromagnetic waves, hence providing them with extraordinary electromagnetic properties. This phenomenon is due to their precise micro and nanostructure design and arrangement instead of the actual bulk material.

Specifically, the structure of metamaterials involves size and spacing that is smaller than the wavelength of electromagnetic radiation. As a result, metamaterials can have a negative refractive index. Here, light, or other radiation, is bent backward as it enters a metamaterial structure – natural materials have positive refractive indexes. In 2001, negative refraction was proven experimentally for the first time by Robert Shelby.

Due to their unique electromagnetic characteristics, metamaterials have a wide and diverse array of potential applications in various industries. One example of current use is in antennas, as they can drastically enhance their function of radiating energy by reducing energy loss. It is worth noting, though, that mass production is difficult to achieve.

Metamaterial antennas are used in wireless communications, Global Positioning System (GPS), and space vehicle navigation industries. Although they could be applied in other sectors such as sound filtering, cloaking devices, or improving solar cells, further studies must be conducted before this becomes a commercially available reality.

Innovation Inspired by Nature

A team of researchers from North Carolina University has conducted studies that have led to the creation of a metamaterial inspired by naturally occurring vascular networks found in living organisms. The metamaterial was fabricated from structural epoxy reinforced with glass fibers. Already, potential uses of this innovation can be seen, such as involvement in the active cooling of various machinery like aircraft and electric vehicles. The research was published in the journal Advanced Materials Technologies on August 16th, 2021.

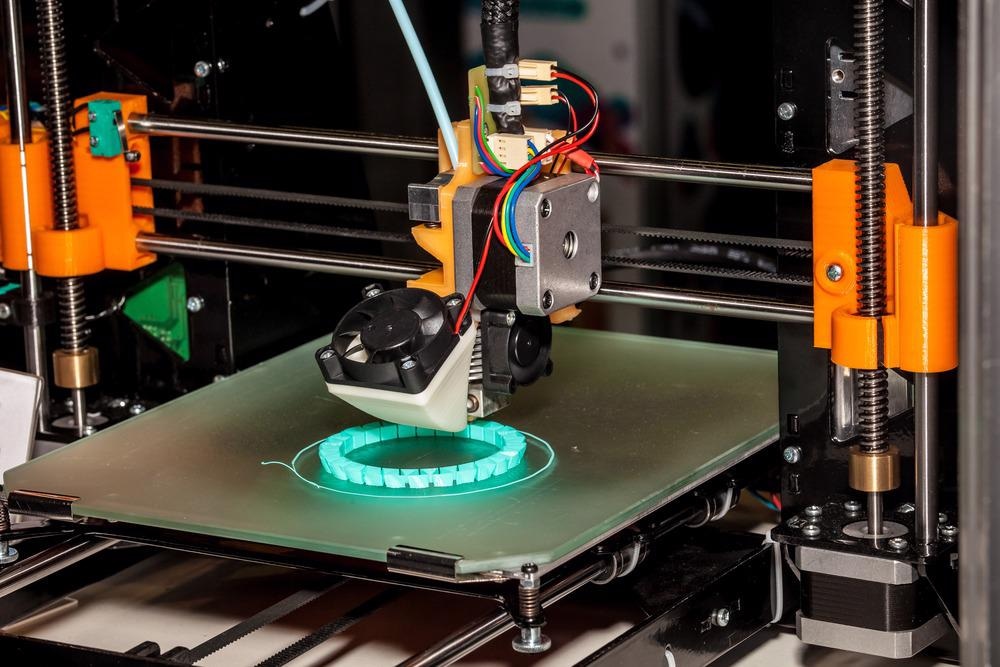

Not only has 3D printing been utilized for the creation of vascularised fiberglass, but also in many other innovations, for example, a chain mail-inspired fabric that stiffens on demand was produced by a team from the California Institute of Technology (Caltech) and Nanyang Technological University (NTU).

The key benefit of vascularised fiberglass is that both the thermal and electromagnetic properties can be modified: by running water through it, the thermal properties can be altered, and by using a liquid metal alloy, the electromagnetic characteristics can be changed. Furthermore, the material produced is cost-effective and significantly lighter than current cooling systems.

Realizing the Benefits of Metamaterials

The field of metamaterials is an advancing industry with many exciting industrial applications. The ability to modify their properties, such as the precise control of their refractive index, enables the discovery of novel applications for a broad range of sectors.

Before this can be realized, further investigations must be conducted so that metamaterials can be used to their full potential and make a significant positive impact globally. Still, with the help of technology such as 3D printing to accelerate the development of novel materials like vascularised fiberglass, the potential for metamaterials to revolutionize a range of industries can be realized.

References and Further Reading

Devi, U., Pejman, R., Phillips, Z.J., Zhang, P., Soghrati, S., Nakshatrala, K.B., Najafi, A.R., Schab, K.R. and Patrick, J.F. (2021) A Microvascular‐Based Multifunctional and Reconfigurable Metamaterial. Advanced Materials Technologies, p.2100433. Available at: https://doi.org/10.1002/admt.202100433

3D Printing Industry. (2021) Engineers enable active cooling and RF communications with new 3D printed metamaterial. [online] Available at: https://3dprintingindustry.com/news/engineers-enable-active-cooling-and-rf-communications-with-new-3d-printed-metamaterial-195745/

Askari, M., et al. (2020) Additive manufacturing of metamaterials: A review. Additive Manufacturing, 36, p.101562. Available at: https://doi.org/10.1016/j.addma.2020.101562

ATRIA Innovation. (2020) What are metamaterials? Properties, benefits and in which fields can they be used. [online] Available at: https://www.atriainnovation.com/en/what-are-metamaterials-properties-benefits-and-in-which-fields-can-they-be-used/

Ma, H.F., Hu, S., Ma, Y.G., Lai, Y. and Esselle, K. (2015) The Applications of Metamaterials. International Journal of Antennas and Propagation, 2015, pp.1–2. Available at: https://doi.org/10.1155/2015/729617

Nader Engheta, Ziolkowski, R.W. and Institute Of Electrical And Electronics Engineers (2006) Metamaterials : physics and engineering explorations. Hoboken, N.J.: Wiley-Interscience.

Nanowerk.com. (2021) Explaining metamaterials and metasurfaces - properties and applications. [online] Available at: https://www.nanowerk.com/what-are-metamaterials.php

Oliveri, G., Werner, D. and Massa, A., (2015) Reconfigurable Electromagnetics Through Metamaterials—A Review. Proceedings of the IEEE, 103(7), pp.1034-1056. Available at: https://doi.org/10.1109/JPROC.2015.2394292

Wu, B., Wang, W., Pacheco, J., Chen, X., Grzegorczyk, T. and Kong, J., (2005) A STUDY OF USING METAMATERIALS AS ANTENNA SUBSTRATE TO ENHANCE GAIN. Progress In Electromagnetics Research, 51, pp.295-328. Available at: http://dx.doi.org/10.2528/PIER04070701

Zhang, X. (2016) Metamaterial. [online] Encyclopedia Britannica. Available at: https://www.britannica.com/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.