One of the biggest problems in additive manufacturing is making complicated materials flow, settle, and solidify precisely the right way. Precision rheology offers a workaround. From printable hydrogels to graphene-filled polymers, advances in measurement and formulation are turning rheology from a lab-side discipline into a frontline enabler of 3D printing.

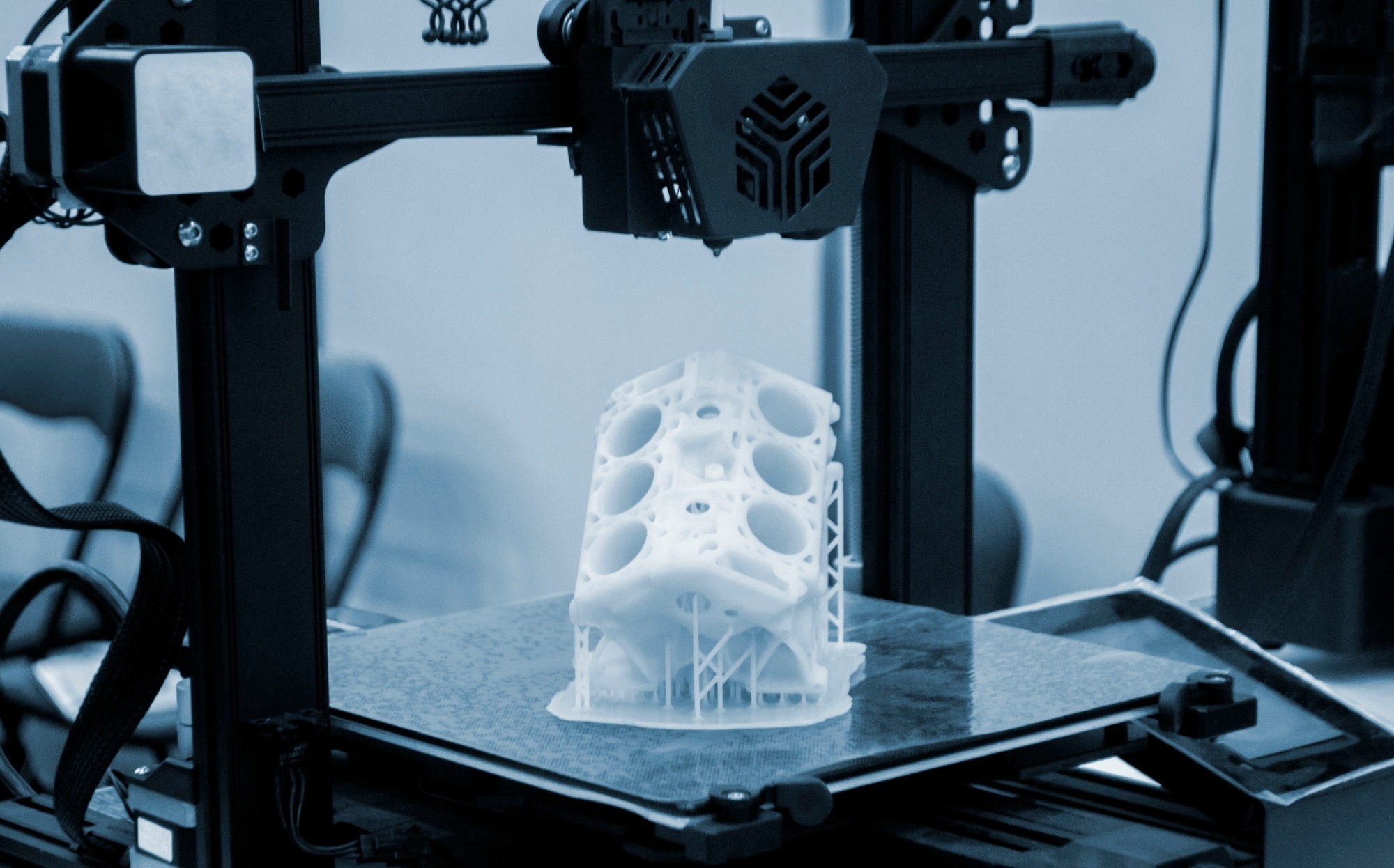

Image Credit: MarinaGrigorivna/Shutterstock.com

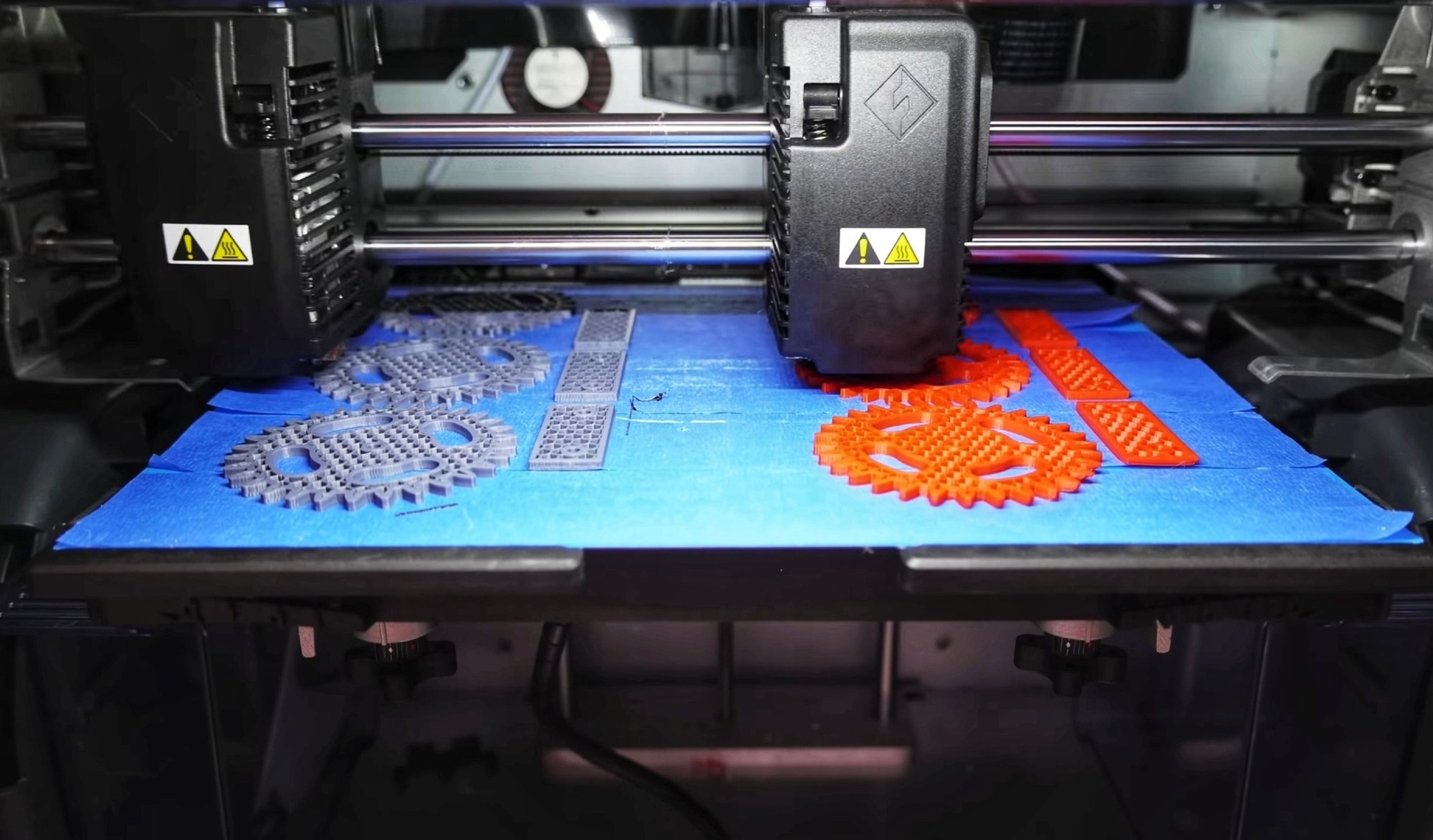

Image Credit: MarinaGrigorivna/Shutterstock.com

Rheological Foundations in Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, relies on pushing material through a nozzle and hoping it behaves consistently. That means flowing when needed, and then holding shape once deposited. The science of such behaviour is rheology. It's the study of how materials deform and flow under applied stress.1

In extrusion and inkjet-based systems, this includes properties like shear-thinning (where discosity decreases with faster flow), viscoelasticity (a combination of fluid and solid-like behaviour), and yield stress (the force needed to initiate movement). Materials that fail to balance these behaviours risk clogging nozzles or collapsing during printing, forming weak, inconsistent structures.1

These properties vary widely across different material types. Hydrogels, for instance, are great at mimicking biological tissues because they can behave like solids and liquids. However, their printability depends on the right balance of viscosity, shear-thinning, and quick gelation. Similarly, polymer inks need careful adjustments in their flow characteristics to achieve clear prints and strong mechanical properties.1,2

Advances in High-Precision Rheological Characterization

High-precision rheological testing is making it easier to understand, map, and predict the behavior of materials under the dynamic stresses typically seen in additive manufacturing. New instruments, including torsional and capillary rheometers, can measure subtle shifts in storage modulus (G'), loss modulus (G''), yield stress, and complex viscosity over a wide range of frequencies and temperatures.

These measurements directly inform how materials are formulated and printed. Microrheological tools, operating at microscopic scales, add another layer of insight, which is useful for materials with internal structure or embedded particles.1

Direct ink writing (DIW) is a common 3D printing method used with fluid materials. For the printed shape to hold, the ink's storage modulus must be greater than the loss modulus, and should recover quickly after extrusion to prevent layer deformation or collapse.

These parameters are assessed through creep/recovery and oscillatory testing, which track how a material responds to stress and whether it can regain its shape. In vat photopolymerization, the low-shear viscosity and photocuring rate must be tightly controlled to ensure smooth recoating and precise crosslinking.1

Download your PDF now!

Material Formulation Enabled by Rheology

Formulating printable materials used to be largely trial and error, testing different ratios and figuring out what sticks. But rheology has changed that. By adjusting variables like polymer type, chain length, and crosslinking agent, researchers can now design hydrogels with precisely tuned gelation times and with desired properties.1,2

Polymer nanocomposites, which often include fillers like graphene, are another complicated challenge. The addition of nanoparticles can greatly improve mechanical performance, but they need to be evenly dispersed and not disruptive to flow. Achieving this requires careful tweaking of extrusion speed, temperature, and additive concentration, all based on rheological data.1,2

Printability and Process Optimization

Good flow is just one aspect of additive manufacturing. Printability, the capacity of a material to be extruded, deposited, and shaped accurately as defined by digital designs, is another important property. Key factors that affect this include viscosity at different shear rates, yield stress, and shear-thinning properties.1,3

With high-precision rheology, researchers can measure these characteristics using tests like frequency sweeps and strain control, helping them to identify the thresholds required to avoid nozzle clogging, bridging, or feature collapse. This understanding is vital for improving the quality of 3D printing.1,3

Process optimization uses rheological data to improve print speed, nozzle size, layer height, and temperature in 3D printing. When 3D printing polymers such as acrylonitrile butadiene styrene (ABS), the optimal storage modulus can lead to better fatigue and flexural strength in the finished product. Additionally, incorporating fillers or varying the processing temperature can fine-tune flow and structural integrity, with each adjustment guided by real-time rheometry.2

Knowing how a part will behave during printing and throughout its useful life is another piece of information that rheology can provide.

For instance, matching the viscoelasticity of biomedical hydrogels to that of living tissue can improve biocompatibility. In industrial parts, rheological insights help predict creep, fatigue, and load-bearing capacity, long before any physical testing.1,2

Image Credit: Cheshiry_cat/Shutterstock.com

Image Credit: Cheshiry_cat/Shutterstock.com

Emerging Directions for Advanced Materials

Modern additive manufacturing increasingly targets multi-material and functionally graded structures, including stimuli-responsive (4D) printed objects. These applications often require highly engineered rheological profiles for sequential or location-specific crosslinking, morphological change over time, or tailored responses to environmental triggers.

Hybrid hydrogels, which use both chemical and physical crosslinks, offer a solution as their flow characteristics can be adjusted through these dual crosslinking methods for improved performance.1

The integration of nanoparticles, biopolymers, and engineered fillers further complicates the rheological landscape but also expands the possibilities for advanced functional devices and structures. Continued improvements in rheological measurement sensitivity and spatial resolution will enable more accurate formulation and processing of these increasingly complicated systems.2

Future Outlook

Additive manufacturing is evolving into a platform where formulation, flow, and function are all tightly integrated. Rheology sits at the heart of this convergence. Without it, high-performance 3D printing is close to guesswork.

Recent developments in measurement techniques, combined with a growing understanding of multiscale structure-property relationships, enable unprecedented control over how materials behave at every stage: in the vat, the nozzle, or the final product. Research continues to refine the relationships between composition, rheology, process, and end-use function, establishing high-precision rheology as a foundational science in additive manufacturing.

References

- Calafel, M. I. et al. (2025). From rheological concepts to additive manufacturing assessment of hydrogel-based materials for advanced bioprinting applications. Materials Advances. DOI:10.1039/d5ma00019j. https://pubs.rsc.org/en/content/articlehtml/2025/ma/d5ma00019j

- Hassanifard, S., & Behdinan, K. (2024). Impact of Rheology-Based Optimum Parameters on Enhancing the Mechanical Properties and Fatigue of Additively Manufactured Acrylonitrile–Butadiene–Styrene/Graphene Nanoplatelet Composites. Polymers, 16(9), 1273. DOI:10.3390/polym16091273. https://www.mdpi.com/2073-4360/16/9/1273

- Barve, P., Bahrami, A., & Shah, S. (2023). Geopolymer 3D printing: A comprehensive review on rheological and structural performance assessment, printing process parameters, and microstructure. Frontiers in Materials, 10, 1241869. DOI:10.3389/fmats.2023.1241869. https://www.frontiersin.org/journals/materials/articles/10.3389/fmats.2023.1241869/full

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.