SensoPRO is the new 64-bit data Analysis solution from Sensofar. SensoPRO provides an environment for QA engineers and technicians to quickly and easily analyze production parameters. When combined with SensoSCAN, the user can obtain 3D data in predefined positions that are transmitted to SensoPRO, which receives the data and applies an analysis algorithm to automatically determine the critical features of the sample.

SensoPRO provides a one-click solution for data acquisition through data analysis.

The application utilizes a module-based approach, where specific Plugin modules can be developed and inserted for the application to hand. This Plugin-based data analysis approach also gives a high degree of flexibility and specificity, making use of targeted algorithms that are trimmed to the exact application needs. Plug-in-based data analysis algorithms provide a high degree of flexibility and new modules can be easily customized to other industry needs.

SensoPRO software solution when combined with their S neox and S mart optical profilers, assists in carrying out rapid and simple quality control in a production line. The SensoPRO software and S line optical profilers simplify the work of the operator, who need only load the sample and follow the step-by-step instructions.

As well as the standard available algorithms for surface analysis, even those for semiconductor packaging industries, custom algorithms for specific applications can also be written.

The results can then be provided in an Excel report in a choice of file formats (.csv, …) that display the data for each measurement item reported. Using defined tolerances, pass/fail data can be displayed, which reduces the time taken by the operator to plan the next course of action for the production line.

Key Features

- Analysis algorithms are better as they are written based on customer requirements

- Guided operation

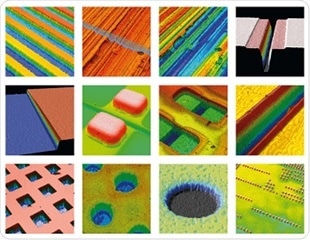

Available Plugins

- Bump

- Double Step Height

- Dual Hole

- Hole

- Laser Cut

- Laser Hole

- Pad

- Rectangular Hole

- Spacer

- Step Height

- Surface Texture

- Surface Texture Profile

- Trace

- Trench