The integrable metrology 3D sensors from Sensofar are the result of over two decades of experience in surface metrology systems.

Robust and Reliable

Frequently, production environments are hostile to metrology equipment: variable conditions, vibrations, aggressive materials, etc. make measurement tasks difficult. The integrable 3D sensors have been developed taking these difficulties into consideration.

The sealed sensor head keeps out particles and debris. The optical assembly consists of no moving parts, so the sensors stay clean and aligned for a long time.

Image Credit: Sensofar Metrology

Compact, Light, and Orientation Independent

The compact size and low weight make designing for integration simple. Functional in any orientation, Sensofar sensors could be placed anywhere where the application requires. Cables are 20 m in length. The sensors are ideally adaptable for both in-line production and robot-mounted sensing applications.

They are developed from the outset to be combined into the toughest manufacturing environments. Small, lightweight with flexible mounting options, Sensofar sensors put high-performance surface metrology right where users require it — at the application.

Image Credit: Sensofar Metrology

Sensofar’s Solutions

3D Sensors from Sensofar are developed to address the top-notch needs in QC and QA applications.

The 3D Sensors range includes flexible systems able to quantify various textures and structures all across varying the surface scale.

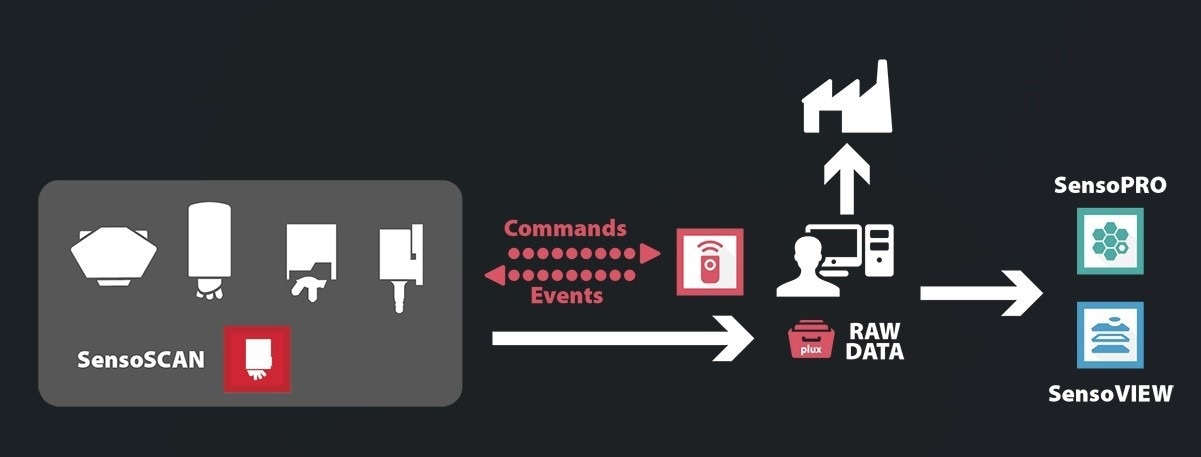

The Software Map

The integrated software and hardware make a complete solution. In the software map, the workflow of measurement is presented: from the programming of the sensor heads on how to obtain the measurements to setting which analysis to perform with the outcomes.

Image Credit: Sensofar Metrology

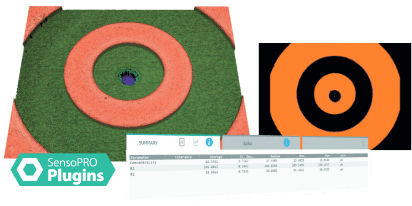

SensoPRO

With the help of SensoPRO, the speed of production line demands has been matched: with custom-based plugin data analysis algorithms, particular features will be detected and analyzed, in an automatic manner, thereby rapidly creating a pass or fail report.

Image Credit: Sensofar Metrology

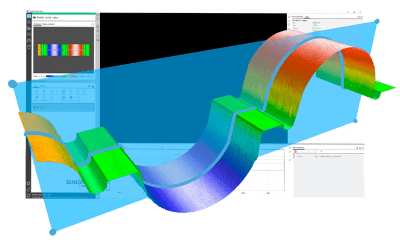

SensoVIEW

SensoVIEW is the perfect software for an extensive range of analysis tasks. It consists of an extensive suite of tools for preliminary examination and analysis of 3D or 2D measurements. It offers roughness or volume calculations and quantifies crucial dimensions with a set of analysis tools, which can be further exported as a report or data set (csv file).

Image Credit: Sensofar Metrology

SDK

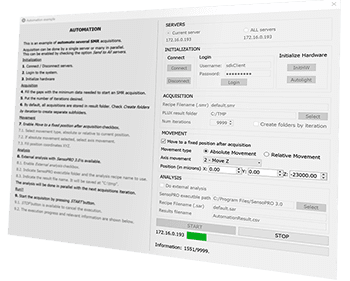

The Software Development Kit (SDK) is a set of tools that allows remote control over one or more sensors. It produces and regulates communication between the client’s computer and the sensors, as well as addressing the obtained data to analysis software.

Image Credit: Sensofar Metrology

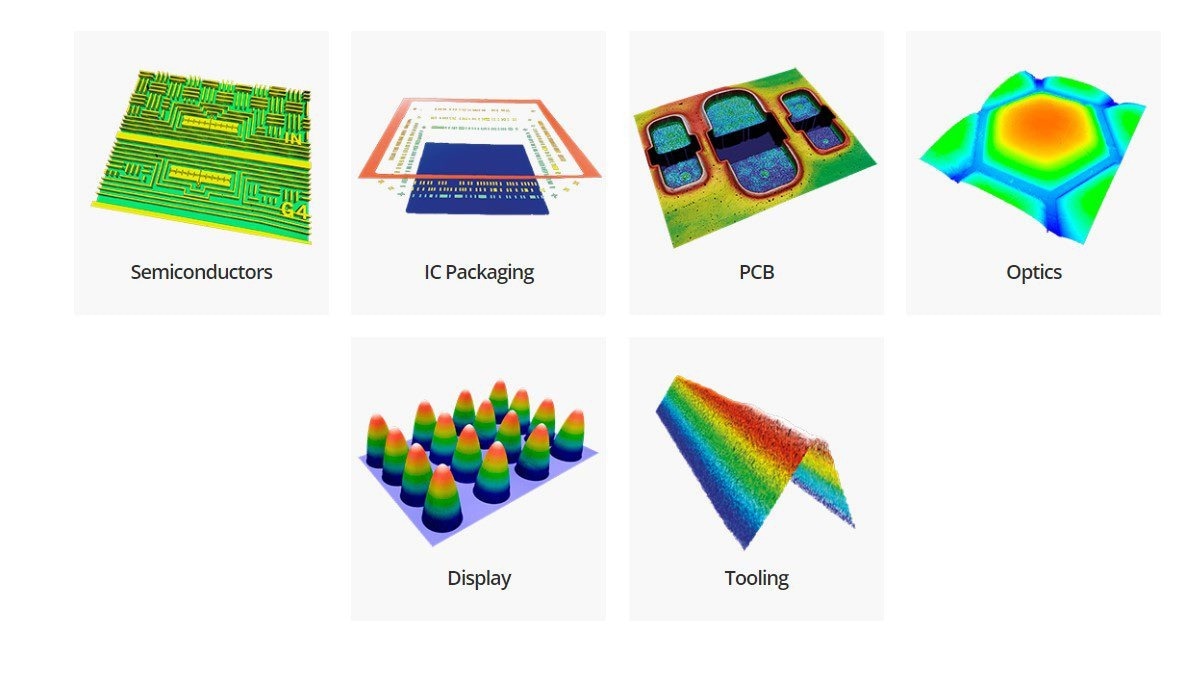

Applications

The integrable sensors have been specially developed to resolve multiple applications in the field of microelectronics, semiconductors, optics and surface finishing. Thus, it helps in covering the big markets of advanced manufacturing and consumer electronics.

Image Credit: Sensofar Metrology

S mart & S onix In-Line 3D Surface Sensors for In-Line Metrology Solutions