May 20 2019

Recyclable plastics that have ring-shaped polymers may be crucial to creating sustainable synthetic materials. In spite of some promising advances, scientists stated, a complete insight into how to process ring polymers into real-world materials remain vague. In a new research, scientists identified a mechanism known as “threading” that occurs when a polymer is stretched – a behavior not seen before. This new understanding may result in new processing techniques for sustainable polymer materials.

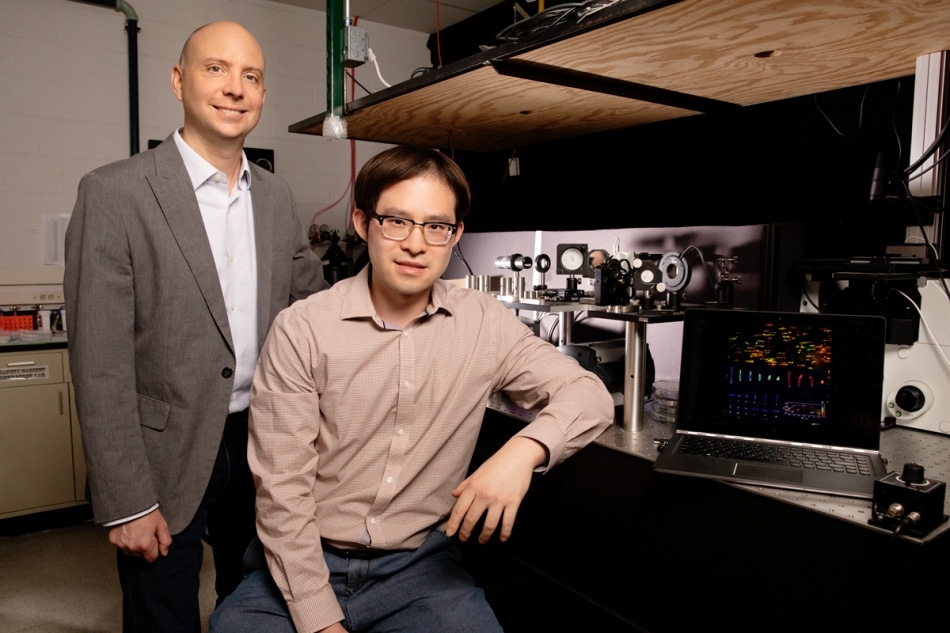

Chemical and biomolecular engineering Professor Charles Schroeder, left, and graduate student Yuecheng (Peter) Zhou study the flow dynamics of ring and linear polymer solutions to tease out clues about how synthetic polymers interact during processing. (Photo by L. Brian Stauffer)

Chemical and biomolecular engineering Professor Charles Schroeder, left, and graduate student Yuecheng (Peter) Zhou study the flow dynamics of ring and linear polymer solutions to tease out clues about how synthetic polymers interact during processing. (Photo by L. Brian Stauffer)

A majority of consumer plastics are combinations of linear polymers. The concept of plastics made only from ring polymers – molecules that form a closed ring – offer an attractive opportunity for sustainability, as demonstrated by the Autonomous Materials Systems group at the Beckman Institute for Advanced Science and Technology. When a single bond holding ring polymers together breaks, the whole molecule disintegrates, causing a breakdown on demand. However, processing such polymers into real-world materials remains a challenge, the scientists said.

A 2013 University of Illinois-led research revealed that ring polymers could be disintegrated with heat, but this has a downside – the resulting plastics would probably become unstable and start to disintegrate in advance.

In the new research, U. of I. scientists Charles Schroeder and Yuecheng (Peter) Zhou study the flow dynamics of DNA-based ring and linear polymer solutions to tease out evidence about how synthetic polymers interact during processing. Their findings were reported in the journal Nature Communications.

We lack a fundamental understanding of how ring polymers stretch and move in flow while navigating around other neighbor polymer chains. This work allowed us to probe these questions at a molecular level.

Charles Schroeder, Study Co-Author and Professor of Chemical and Biomolecular Engineering, Beckman Institute, University of Illinois

In Schroeder’s lab, the scientists stretch and squeeze polymers, causing them to flow and enabling direct observation of the behavior of independent molecules using single-molecule fluorescence microscopy.

There is a fluctuation in the shape of the ring polymers and this depends on the concentration of linear polymers in the solution. We do not see this behavior in pure solutions of ring or linear polymers, so this tells us that something unique is happening in mixed solutions.

Zhou, Study Lead Author and Graduate Student, Beckman Institute, University of Illinois

Using a mixture of direct single-molecule observations and physical measurements, the researchers decided that the variations in the shape of the ring polymers happen due to linear molecules thread themselves through the ring molecules when stressed, causing the ring shape to change under fluid flow.

“We observed this behavior even when there is a very low concentration of linear polymers in the mix,” Zhou said. “This suggests that it only takes a very minute level of contamination to cause this phenomenon.”

This threading of linear polymers via ring polymers when in stress is something that had been hypothesized before, using bulk-scale studies of the physical properties, but currently it has been seen at the molecular scale, the scientists said.

“Bulk studies typically mask the importance of what is going on at the smaller scale,” Schroeder said.

How these interpretations will convert into further development of sustainable consumer plastics remains uncertain, the scientists said. However, any understanding into the core molecular properties of mixed-polymer solutions is a step forward.

To make pure ring polymer plastics a reality, we need to understand both mixed and pure solutions at a fundamental level. Once we can figure out how they work, then we can move on to synthesizing them and ultimately how to use them in sustainable consumer plastics.

Charles Schroeder, Study Co-Author and Professor of Chemical and Biomolecular Engineering, Beckman Institute, University of Illinois

Former U. of I. graduate student Kai-Wen Hsiao, Kathryn E. Regan and Rae M. Robertson-Anderson, of the University of San Diego, and Dejie Kong and Gregory B. McKenna, of Texas Tech University, contributed to this study.

The research was supported by the National Science Foundation.