Skoltech researchers have investigated a promising type of composite materials in terms of their shape memory behavior: how they resume their original shape following deformation if exposed to the right temperature or other conditions.

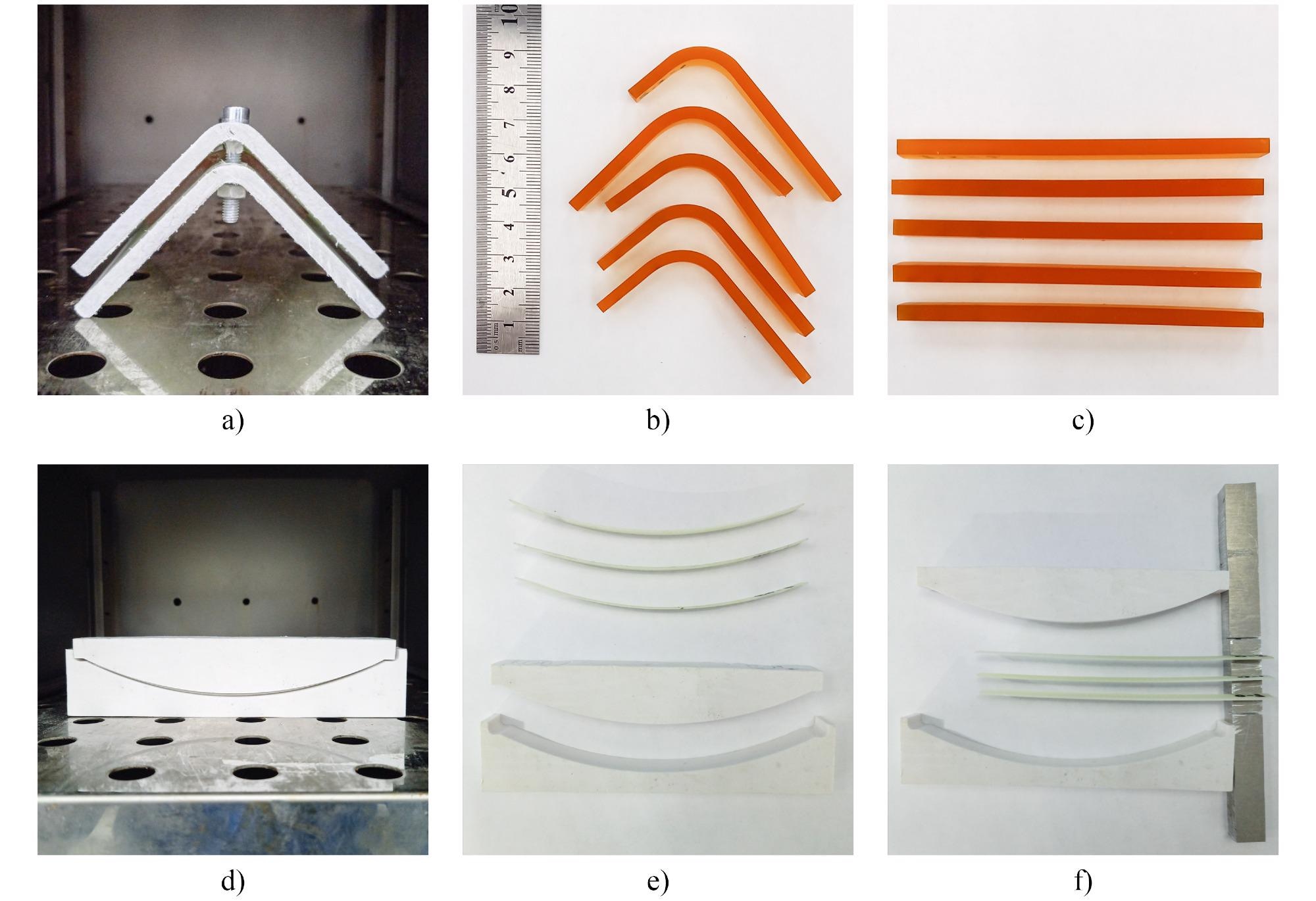

Shape memory testing of cured resin and pultruded composite specimens: (a) Deformed specimen of cured resin in the test fixture after heating; (b) cured resin specimens after shape fixing; (c) cured resin specimens after shape recovery; (d) deformed specimen of pultruded composite in the test fixture after heating; (e) geometry of pultruded composite specimen after shape fixing as compared to geometry of the test fixture; and (f) pultruded composite specimen after shape recovery. Image Credit: Roman Korotkov et al./Composites Part A: Applied Science and Manufacturing.

Shape memory testing of cured resin and pultruded composite specimens: (a) Deformed specimen of cured resin in the test fixture after heating; (b) cured resin specimens after shape fixing; (c) cured resin specimens after shape recovery; (d) deformed specimen of pultruded composite in the test fixture after heating; (e) geometry of pultruded composite specimen after shape fixing as compared to geometry of the test fixture; and (f) pultruded composite specimen after shape recovery. Image Credit: Roman Korotkov et al./Composites Part A: Applied Science and Manufacturing.

The materials studied were glass fiber-reinforced epoxy-based flat laminates, produced with a technique called pultrusion. While it has considerable potential for manufacturing composites with shape memory for electronics, biomedicine, and more, the method’s application to such materials is examined for the first time in the Skoltech-led study reported in Composites Part A: Applied Science and Manufacturing.

Shape memory polymers, or SMPs, are materials that can recover their initial shape under external stimuli such as temperature, light, moisture, acidity, electricity, or electromagnetic field. They are widely used in the aerospace, biomedical, and automotive industries, as well as in 4D printing, temperature sensors, and electronic devices.

SMPs are often reinforced with carbon, basalt, or glass fibers, resulting in composite materials with superior properties. A number of techniques are used for SMP composite manufacturing, most of them fairly well-studied. Surprisingly, until now there have been no studies on the shape memory effect in composites produced by pultrusion — the most efficient composite manufacturing process available. It is a fast, versatile, and low-waste technology that could potentially yield new types of shape memory structural components with unique combinations of geometries and mechanical properties, impossible to produce with other methods.

“In this study, we investigated the shape memory behavior and mechanical characteristics of epoxy-based pultruded flat laminates reinforced with unidirectional glass fibers. The analysis also encompassed the resin cure kinetics and the thermomechanical and thermophysical properties of the cured resin,” commented the project’s PI, Alexander Safonov of the Skoltech Center for Design, Manufacturing and Materials.

“Our findings may be used for further numerical simulations and the optimization of the pultrusion process. Besides, the results demonstrate that pultruded SMPCs show significant promise for structural applications,” the researcher added.