Reviewed by Lexie CornerMay 29 2025

An international team led by HZB chemist Michelle Browne has conducted a detailed study demonstrating the potential of MXene-based materials for future large-scale applications.

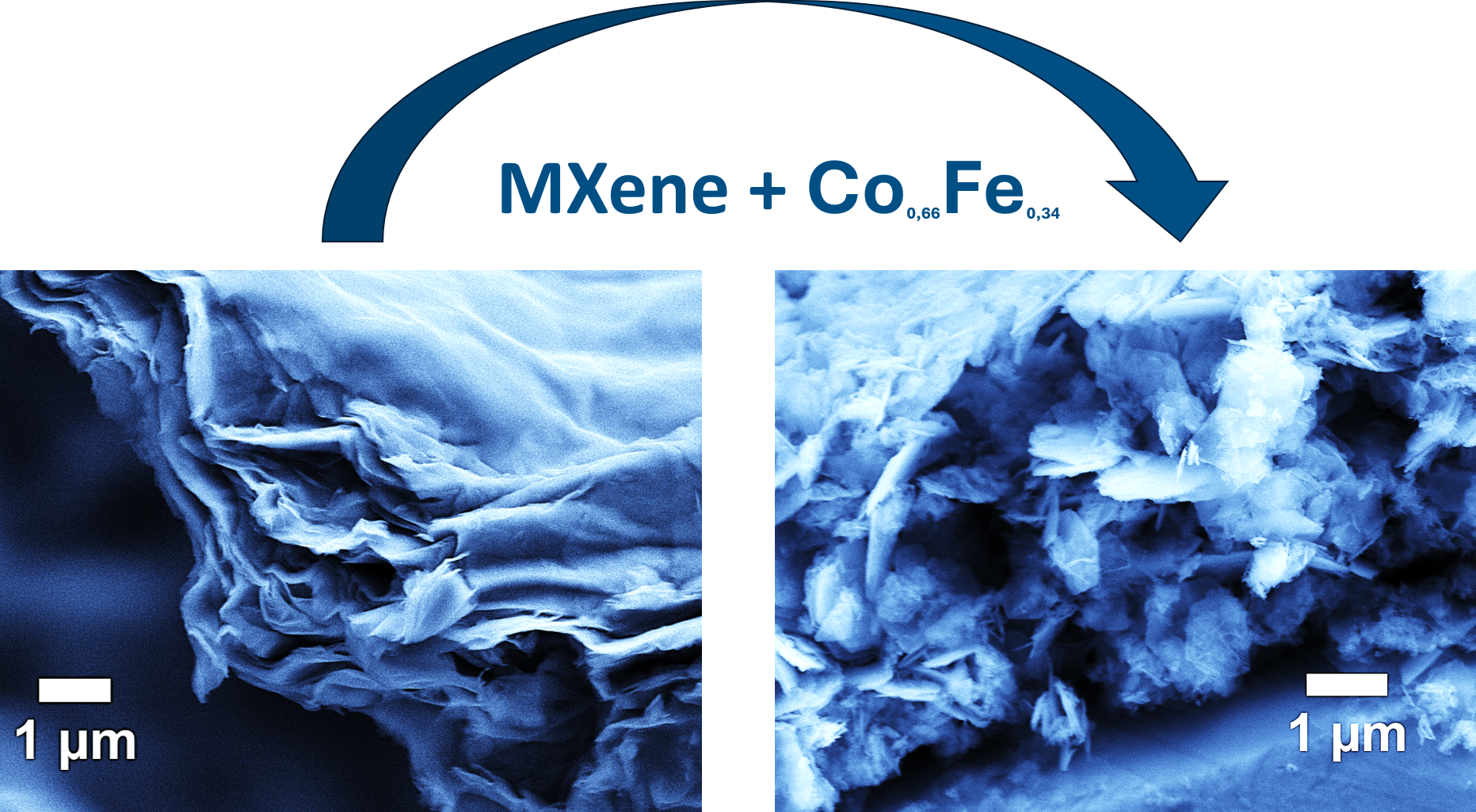

The image on the left shows the flaky structure of the MXene sample under a scanning electron microscope. The image on the right shows the resulting composite material after cobalt and iron were incorporated into the MXene structure. Image Credit: HZB

The image on the left shows the flaky structure of the MXene sample under a scanning electron microscope. The image on the right shows the resulting composite material after cobalt and iron were incorporated into the MXene structure. Image Credit: HZB

MXenes are effective at supporting catalytically active particles. This property can be used to develop improved catalyst materials that help accelerate the oxygen evolution reaction, a key step in producing green hydrogen through electrolysis powered by solar or wind energy.

Green hydrogen is expected to play an important role in the future energy system. It can serve as a form of chemical energy storage, a feedstock in the chemical industry, and a source of low-emission fuels.

If the energy used for electrolysis (the process of splitting water into hydrogen and oxygen) comes from solar or wind power, green hydrogen can be produced with minimal greenhouse gas emissions. However, specific catalysts are needed to speed up the reactions at the two electrodes.

Without effective catalysts, the oxygen evolution reaction proceeds slowly and requires more energy. Current catalysts are often made from precious metals, which are limited in supply and expensive. To make green hydrogen widely available and affordable, catalysts made from more abundant materials are needed.

Flaky Structures

Michelle Browne leads a team at HZB that is developing new catalyst materials based on MXenes. MXenes are layered structures made of carbon and transition metals. Catalytically active particles can attach to the internal surfaces of these layers, enhancing their catalytic performance. Recent research confirms the effectiveness of this approach.

Can Kaplan, the study’s lead author, conducted experiments using several types of vanadium carbide MXenes. During his Ph.D., he participated in an exchange program that enabled him to carry out part of his research at the laboratory of his collaborators at Linköping University in Sweden.

The Role of Vacancies

There, we synthesized two MXene variants: pure V2CTx and V1.8CTx with 10% vanadium vacancies. These vanadium vacancies ensure that the internal surface area of this variant is significantly larger.

Can Kaplan, Study Lead Author, Helmholtz-Zentrum Berlin

Embedding CoFe into MXene

In Michelle Browne’s laboratory at HZB, Can Kaplan developed a multi-step chemical process to embed Co0.66Fe0.34 catalyst particles into MXene. Scanning electron microscope images confirmed the success of this approach: while pure MXenes display a layered, pastry-like structure, the addition of cobalt-iron particles leads to noticeable structural changes.

Best Efficiency: CoFe in the Vanadium Deficient MXene

The researchers then compared the performance of different catalyst samples during electrolysis: pure cobalt-iron particles and two types of MXene-based materials. While the pure cobalt-iron catalyst showed catalytic activity, significantly higher performance was observed when the particles were embedded in MXene.

The most effective catalyst was the one where the cobalt-iron particles were incorporated into MXene with a high number of vanadium vacancies. These structural defects appear to enhance the catalytic performance.

To understand the changes occurring during electrolysis, the team used in situ X-ray absorption spectroscopy at the SOLEIL synchrotron facility in France. This allowed them to track the oxidation states of iron and cobalt during the reaction.

Promising Path to a New Class of Catalysts

Kaplan added, “We tested these catalysts on both a laboratory scale and in a much larger electrolyser. This makes our results really meaningful and interesting for industrial applications.”

“Currently, the industry has not yet considered MXene as a carrier material for catalytically active particles on the radar. We are conducting basic research here, but with clear prospects: on applications. Our results have now provided initial insights into the complex interplay between the carrier structure, the embedding of catalytically active particles, and catalytic activity,” added Michelle Browne.

Michelle Browne found that MXene is a good choice for developing creative, highly efficient, and cost-effective catalysts.

Journal Reference:

Kaplan, C., et al. (2025). Enhancing CoFe Catalysts with V2CTX MXene-Derived Materials for Anion Exchange Membrane Electrolyzers. Advanced Functional Materials. doi.org/10.1002/adfm.202503842