By Muhammad OsamaReviewed by Lexie CornerJun 12 2025

By Muhammad OsamaReviewed by Lexie CornerJun 12 2025A recent study published in Macromolecular Materials and Engineering presents a new method for creating antimicrobial polymer blends designed for 3D printing.

The approach addresses a growing need in healthcare: producing materials that can resist bacterial contamination, especially in environments where drug-resistant bacteria are increasingly common.

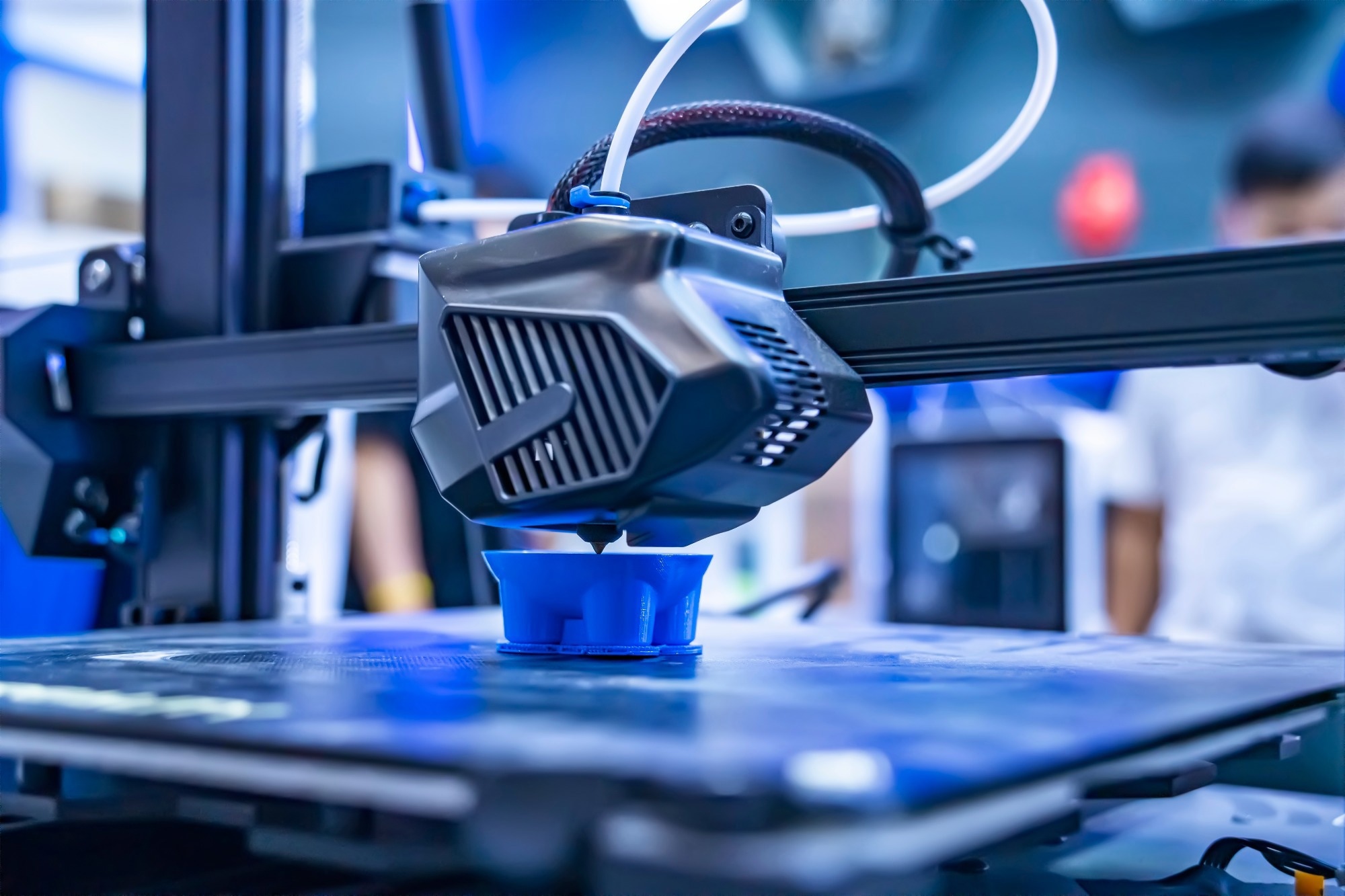

Image Credit: asharkyu/Shutterstock.com

Why Antimicrobial Materials Matter in Medicine

Antimicrobial materials are crucial for preventing bacterial contamination on surfaces used in medical settings. Plastics, mainly used for surgical tools and tubing, often serve as breeding grounds for harmful microbes, including drug-resistant bacteria from the ESKAPEE group.

Traditional disinfectants face challenges such as short-term effectiveness and environmental toxicity. Therefore, developing materials that can kill microbes on contact and resist colonization is key. Antimicrobial polymers with positively charged groups, like quaternary ammonium compounds (QACs), offer a promising solution, but integrating these into high-performance polymers suitable for selective laser sintering (SLS) remains challenging.

How the Materials Were Developed and Tested

The antimicrobial polymer, SMI-Pq12, was synthesized in two steps. First, a styrene-maleic anhydride copolymer was converted into an imide intermediate using dimethylaminopropylamine. This was then quaternized with 1-bromododecane. Researchers blended this polymer with PA11 in different weight ratios using dichloromethane as a solvent to create films.

To assess antimicrobial activity, the films were exposed to cultures of Staphylococcus aureus (Gram-positive) and Escherichia coli (Gram-negative). A resazurin-based metabolic assay was used to measure bacterial survival.

The materials were further analyzed using:

- Differential Scanning Calorimetry (DSC)

- Powder X-Ray Diffraction (PXRD)

- Fourier-Transform Infrared Spectroscopy (FTIR)

- Nuclear Magnetic Resonance (NMR)

- Scanning Electron Microscopy (SEM)

- Micro-computed Tomography (micro-CT)

- Tensile testing

For the 3D printing trial, the team selected a 95 % PA11 blend. It was processed using an EOS P 396 E SLS printer due to its material availability and ease of printing.

What the Tests Showed

Thermal and Structural Behavior

DSC revealed two melting points in the blends, indicating both primary and secondary crystallization of PA11. Pure PA11 melted at 186.7 °C. Adding SMI-Pq12 lowered both melting and crystallization temperatures, which points to reduced crystallinity.

PXRD confirmed that PA11 retained its pseudohexagonal γ-phase, with some shift toward the α-phase as SMI-Pq12 content increased. FTIR data suggested possible hydrogen bonding between the two polymers. Melting point trends from the Hoffman-Weeks method also supported changes in crystallinity caused by blending.

Antimicrobial Activity and 3D Print Results

The blends showed strong antibacterial effects against both S. aureus and E. coli. Pure PA11, in contrast, had little impact. Blends containing 15–25 % SMI-Pq12 achieved complete bacterial killing, with up to a 6-log reduction. The materials were more effective against S. aureus, which is easier to kill due to its simpler cell wall structure.

The 95 % PA11 blend was successfully printed using SLS. Thermal data helped determine the optimal bed temperature at 183.5 °C. Micro-CT scans showed low porosity, about 1.85%. While some phase separation occurred—likely from uneven powder mixing—the printed parts still retained their antimicrobial function. SEM images showed rougher surfaces in the blends, likely from incomplete melting.

Mechanical tests found that the strength of printed parts depended on print orientation. Horizontally printed samples performed better. The 95 % blend had slightly lower strength than pure PA11 but remained within acceptable ranges for medical use.

What This Means for Medical Manufacturing

These antimicrobial polymer blends offer a practical path toward 3D-printed medical devices that can reduce the risk of infection. Applications could include surgical gowns, tubing, implants, and prosthetics.

Polymer blending also provides a cost-effective and scalable way to improve the functionality of commonly used plastics.

Download your PDF copy now!

Looking Ahead

The study shows that PA11 blended with QAC-functionalized SMI maintains key properties for 3D printing while gaining strong antimicrobial performance. The materials preserve thermal stability, are printable by SLS, and effectively eliminate bacteria, even after printing.

While rough surface texture and phase separation are limitations, the core antimicrobial effect remains intact. Mechanical strength, though slightly lower than pure PA11, is still suitable for many medical applications.

Future work should focus on improving material uniformity, testing durability over time, and refining printing parameters. These efforts could further expand the use of antimicrobial 3D printing materials in healthcare, helping to produce safer, infection-resistant devices.

Journal Reference

Daniels, M., et al. (2025). 3D Printable Antimicrobial Polymer Blend. Macromolecular Materials and Engineering. DOI: 10.1002/mame.202400071, https://onlinelibrary.wiley.com/doi/10.1002/mame.202400071

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.