Researchers from Harbin Institute of Technology (Shenzhen) and Johannes Gutenberg University Mainz have created a dual-function catalyst material that tackles two significant limitations in Li-O2 battery development.

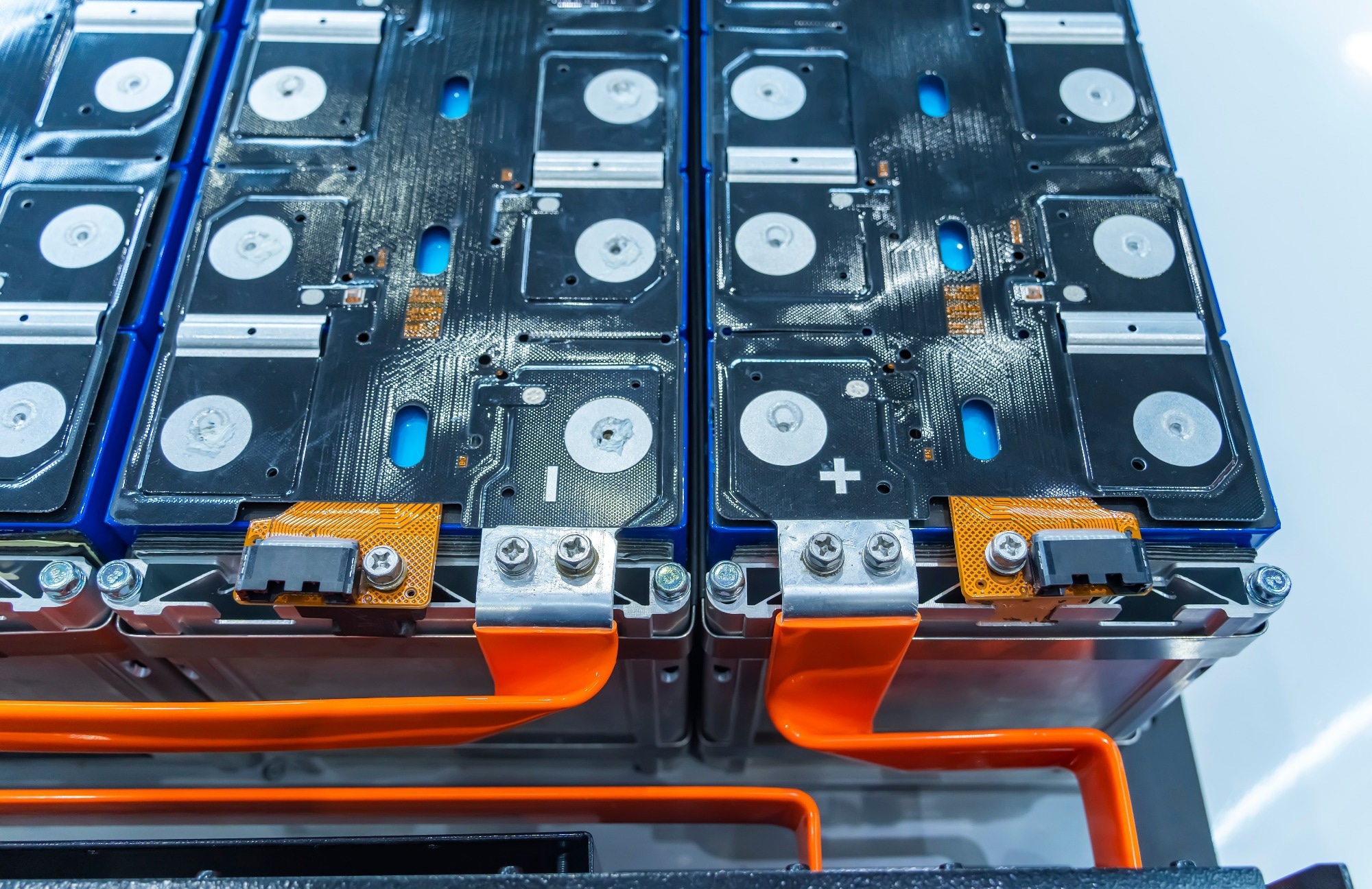

Image Credit: asharkyu/Shutterstock.com

Lithium–oxygen (Li–O2) batteries offer more than ten times the energy density of traditional lithium-ion batteries, making them an attractive option for electric vehicles and large-scale energy storage. But they come with significant challenges: sluggish reaction kinetics at the cathode and instability of the lithium metal anode. These issues lead to rapid capacity loss, high overpotential, and the growth of dangerous dendrites.

While previous research has made progress on either the cathode or the anode, an integrated solution has remained out of reach. Additionally, common discharge byproducts like Li2O2 and Li2CO3 tend to clog pores and degrade overall performance. Tackling these persistent problems requires new materials and strategies that work across the entire system.

Researchers from Harbin Institute of Technology (Shenzhen) and Johannes Gutenberg University Mainz have developed a dual-function catalyst that addresses both major hurdles in Li–O2 battery development.

Their study, published in eScience, presents a low-loading atomic nickel catalyst (Ni–N/rGO) that boosts cathode reaction efficiency while protecting the lithium metal anode. This combined approach not only improves energy efficiency and cycle life but also offers valuable insight into charge transport and lithium deposition behavior, marking a promising step toward practical, high-performance Li–O2 batteries.

The team engineered atomic-scale nickel sites, both single atoms and nanoclusters, dispersed on nitrogen-doped reduced graphene oxide (rGO). This material, named Ni2–N/rGO, demonstrated excellent catalytic activity for both the oxygen reduction and evolution reactions (ORR/OER).

Compared to conventional cathodes, the new design delivered a discharge capacity exceeding 16,000 mAh g-1 and stable performance over 200 cycles. DFT simulations revealed that adjacent atomic nickel sites improve LiO₂ adsorption and lower the energy barrier for Li₂O₂ breakdown, leading to a reduced overpotential of just 1.08 V.

Beyond catalysis, Ni2–N/rGO doubles as a protective coating for lithium metal anodes. When applied, it significantly cuts down dendrite formation and surface corrosion, extending battery life to 300 cycles even under high current.

Microscopy and impedance spectroscopy confirmed that the protective layer retains its structure and supports smooth Li+ migration. Additional analysis using DEMS and XPS showed that the catalyst promotes reversible reactions without creating harmful byproducts.

By addressing critical issues at both electrodes, this multifunctional material showcases how atomic-level engineering can push the boundaries of Li–O2 battery performance.

This work is significant because it solves two long-standing problems in lithium–oxygen batteries using a single material. By designing atomically dispersed nickel catalysts that simultaneously enhance cathode reaction kinetics and stabilize the lithium anode, we’ve shown a clear path toward practical, high-performance Li–O₂ systems.

The combination of theory, in situ characterization, and real-world cycling tests makes this a compelling framework for future research.

Dr. Deping Li, Study Senior Author and Professor, School of Materials Science and Engineering, Harbin Institute of Technology

The dual-role Ni–N/rGO catalyst offers a scalable and versatile solution to longstanding bottlenecks in Li–O2 battery design. Its ability to lower polarization, suppress dendrites, and support high-rate cycling could accelerate the rollout of next-generation batteries in electric vehicles, portable devices, and grid applications.

More broadly, the principles behind this work, atomic-level material design, multifunctionality, and coordinated electrode engineering, may influence future developments across catalysis, electrochemistry, and materials science. Upcoming research will focus on refining synthesis methods, reducing costs, and adapting the material for use in other energy technologies.

Journal Reference:

Bai, T., et al. (2025) Atomic Ni-catalyzed cathode and stabilized Li metal anode for high-performance Li–O2 batteries. eScience. doi.org/10.1016/j.esci.2024.100310