| Paper is such a versatile and useful display material. It’s thin, light, flexible and reasonably robust and perhaps just as importantly, you can read it anywhere. However, it lacks one of the essential benefits of electronic displays instant erasure and reuse, millions of times over, without wearing out, which is why our libraries are packed with paperbacks and we pick up a fresh newspaper every day. Now, thanks to new electronic materials, we could be about to enter an era in which books, magazines and newspapers are delivered, wirelesslv, to thin, flexible plastic displays, convenient for reading whether on a crowded train or beach, just like the media they aim to replace. Plastic Transistors Overcome Flexibility Issues Until now, a major hurdle in creating electronic paper has been the flexibility of circuit boards. Silicon transistors, which are used in computer displays to produce an image on a laptop screen, for example, are too rigid. They can store huge amounts of data in a relatively small device, but they don’t offer the same comfort and pleasure as reading a normal paperback. However, this is set to change with the twin developments of plastic transistors and electronic ink for so-called ‘e-book readers’. |

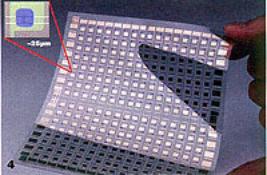

| | Figure 1. Flexible circuit technology, compliments of plastic technology. | The Advent of Electronic Paper The first sheets of electronic paper were demonstrated in 2000 by Bell Laboratories, the research and development unit of Lucent Technologies, and E Ink Corporation. They consist of a 160cm2 display area made up of several hundred pixels, and incorporate two ground-breaking developments - E Ink’s electronic ink and Lucent’s active-matrix drive circuits printed on plastic. ‘Plastics have the advantage of being lightweight, mechanically flexible and robust (unlike brittle inorganic materials such as silicon),’ says John A Rogers, Director of Nanotechnology Research at Bell Labs. ‘They are also compatible with high speed printing techniques.’ Requirements for e-Publications Rogers sites the key ingredients for producing e-publications with ‘real’ pages as mechanically flexible circuit technology (i.e. materials and designs), low-cost printing techniques for building the circuits, and mechanically flexible electronic ink. ‘Our electronic paper displays demonstrate all of these components together in a single system,’ he says. Page Turning Technology The device that allows a reader to ‘turn pages’ electronically is a simple array of transistors arranged on an x-y grid. There is one transistor for each pixel, and the prototype e-paper has 256 of them -16 rows with 16 pixels. A key technology for producing the transistors on a flexible substrate is microcontact printing (μCP) This involves a microfabricated ‘rubber stamp’ typically made of polydimethylsiloxane (PDMS), which can transfer a patterned monolayer of organic molecules onto a substrate. In this prototype, the substrate is a gold layer, 20nm thick, which serves as the source/drain level of the transistors. Another important detail is the use of the organic semiconductor material, pentacene, in the transistors. Unlike the silicon-on-glass technology used in liquid crystal displays, this material is mechanically flexible, and it can be deposited on plastic substrates at low temperatures. Electronic Inks To produce electronic paper displays, ‘inks’ must be laminated onto these sheets of active matrix drive circuitry. Currently there are two types of electronic inks in commercial use in large-scale signs. E Ink’s Electronic Ink E Ink’s electronic ink uses the principal of electrophoresis, the movement imparted by an electric field to charged particles that are suspended in a liquid. The ink contains millions of tiny ‘switchable’ polymer microcapsules. Each transparent microcapsule contains hundred; of positively charged, sub-micron solid spheres of white titanium dioxide an negatively charged black particles suspended, in a clear fluid. These capsules are printed between thin, flexible electrodes. When the to electrode has a positive charge, the negatively charged particles are attracted t the top of the capsules where the become visible to the user, producing white page. When the charge is reverse the particles are repelled, making the capsules look darker. Suspended in water, the microcapsules can be printed on paper or electrode-bearing materials just like ink. The spaces between the electrodes are small enough to give a resolution of 300 monochrome dots per inch (dpi). Gyricon’s Electronic Ink Technology Gyricon Media Inc’s paper-like display technology is currently being, marketed as SmartPaper and incorporates the ‘gyricon’ electronic ink technology originally development by Xerox’s Palo Alto Research Centre (PARC). Produced in a roll like conventional paper and no thicker than a latex glove, it is actually two sheets of thin plastic with millions of tiny bichromal beads embedded in between. It is made by mixing tiny plastic beads, each just 0.03-0.1 millimetres in diameter, into molten, transparent silicone rubber. Each bead is white on one side, black on the other. Having been cooled on slabs and cut into sheets, the rubber is next soaked in oil, which it sucks up like a mop. As it does so, the sheets expand and oil-filled pockets form around the beads, which can then float and rotate freely. The beads are ‘bichromal’, with hemispheres of two contrasting colours (e.g. black and white, or red and white). Each bead is given an electric charge that is slightly greater on one side than the other. When an electric field is applied to the surface of the sheet, the beads rotate to present a particular coloured side to the viewer. The image remains until new voltage patterns are applied. Coloured Electronic Inks Developments in electronic inks are now producing the first colour versions. Based on its monochrome e-paper, E Ink has now succeeded in making a system that works in full colour. Developed with Japanese printing company Toppan, the process requires a fine coloured filter to be laid across the top of the monochrome display - the same trick that lends colour to LCDs. The filter makes each pixel appear as red, green or blue when the pixel below it is white. When the pixel is black, the filter above reflects very little light so no colour is seen. When Will e-Books be Available? So when are we likely to see e-books using this technology? ‘Some engineering work will be required to convert the materials and processing techniques that we use for our electronic paper displays into saleable, high-volume products,’ explains Rogers. ‘I estimate that it will be no longer than 3-5 years before ultrathin, lightweight, mechanically flexible displays appear on the market in some form.’ Nevertheless, as paper-like as it may become, electronic paper may never feel exactly like the original, and the first versions of equipment using this technology will probably be similar to what is available - at least in terms of size and weight. However, as the technology that makes it possible to print circuitry onto flexible surfaces evolves, we can expect to see the look of the devices to change dramatically. The Future for e-Books Many readers like the aesthetics of a bound book, and so this new technology may not convince those people to throw away their paperbacks. However, it certainly has positive implications for applications such as e-newspapers, which could ‘redraw’ headlines throughout the day, and for e-books, which could be used while travelling or taking a continuing education course, particularly as the technology starts to focus on creating e-books that look more like old-fashioned paper. Ultimately, could e-books ever replace the classic paperback? ‘Maybe,’ says Rogers, ‘but it will take many years for everyone to switch completely.’ In fact, as Rogers points out, in many ways, ordinary books are very nice pieces of technology themselves. |