Flexible process control software allows machines from ficonTEC to be more than just the sum of their parts.

ficonTEC has always maintained a distinctive modular approach to machine design, with this development path proving true for the company’s software as well as its hardware. Process Control Master (PCM) is ficonTEC’s easy to use, process-orientated control interface and application software.

The software is included with all turn-key, ready-to-use machines and multi-machine assembly lines.

PCM includes a user-friendly machine/process GUI which incorporates the system management, machine vision and active positioning routines necessary to reliably and repeatably drive bonding process and passive/active alignment equipment.

It is also capable of automated characterization and electro-optical testing tasks. This includes many standard tests such as temperature dependence measurements, spectral measurements, optical power insertion losses and electrical/optical bandwidth. It can also accommodate more complicated modular instrumentation such as tunable laser sources, optical switches and multi-channel power meters.

Versatile, scalable options facilitate customized assembly and testing solutions that are well suited for early device development and the introduction of new products as well as for production.

PCM has a proven track record in high-volume environments, having already tackled the issue of progressively more complex combined electro-optical testing through the transition to more integrated photonic devices.

Automated testing sequences and protocols are improved by directly interfacing with an SQL database, providing access to statistical analysis of the data for traceability and analysis.

Lastly, PCM is adaptable, allowing for as much (or as little) user intervention as required. It can also be used remotely, making it suitable for any working style from fully flexible to fully automatic, to fully remote.

The key features of the software include:

- System-wide implementation, providing a consistent ‘look and feel’ across all machines

- Development tools including debug, camera view, position/jog panel, etc.

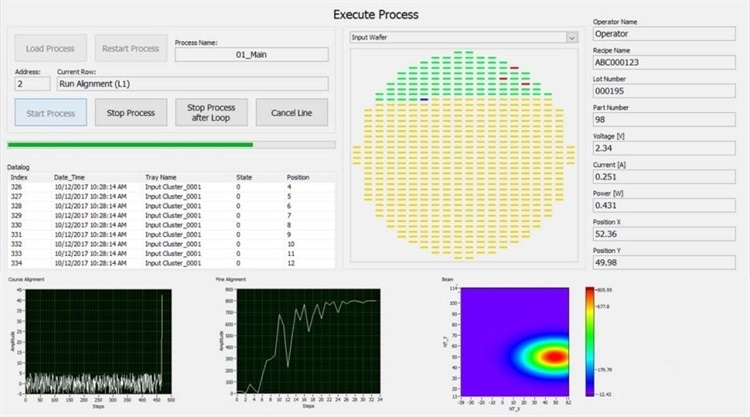

- Adaptable interface, able to display real-time operational data

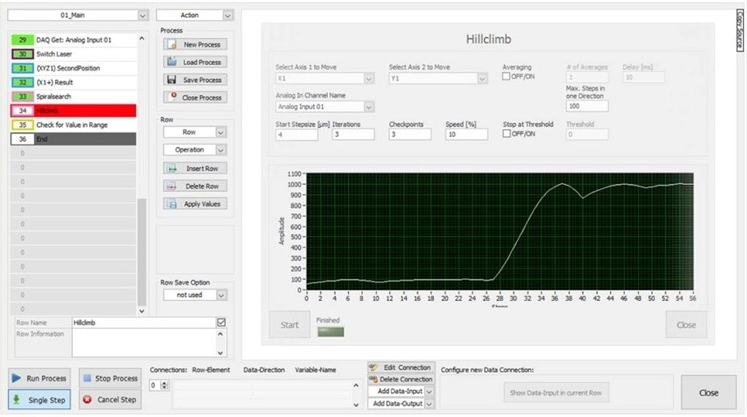

- Process Editor for fully configurable process sequencing

- Recipe-based management of process parameters and steps

- Flexible data import and export, ideal for process/yield monitoring

- ‘Crash protection’ boundaries for motion systems

- Deep Learning tools designed for optical inspection

- SQL database storage of component data and process parameters

- AI-driven Machine Learning for performance analytics

- Remote service and software upgrades, deliverable via the Internet

- Software drivers allow for direct interfacing with a diverse array of instrumentation

- Substantial, powerful library of test and assembly functions

- Component tracking from input/output trays and wafers

- Pre-loaded with machine vision routines and algorithms

- Ideal for both stand-alone systems and multi-machine configurations

- Logging of performance data and operation-critical process steps

It is possible to optimize both the process sequence and cycle time through close collaboration on specific manufacturing steps.

ficonTEC can assist customers with process optimization at every stage of development and realization, particularly as volume requirements increase. Through a close working relationship with customers, the company can combine its wide-ranging experience with technical process control knowhow to support the production process design, including any features related to software control.

This is especially important when interpreting manual assembly and testing protocols as part of the shift from prototyping or low volume to mass production.

The PCM software platform delivers flexible and effective process sequencing and tuning which can then be optimized further following quantification, for example by making use of the detailed statistical data stored in the SQL database.

Cost per item, cycle time, device performance and yield can be optimized within the parameter space permitted by the production process. This is possible within a single cell machine, or, if required, across whole production lines made up of multiple in-line machines.

Finally, a Revision Control Server (RCS) can be employed to synchronize process parameters across all lines for high-volume applications which utilize several identical lines. This ensures repeatability and consistency of both performance and yield. The RCS can be administered remotely or locally, though the former has clear advantages for global players in the photonics market.

ficonTEC offers a dependable, proven route to high-volume manufacturing. This is most effective when collaboration begins in the early stages, for example, by optimizing each step from the design stage, using advanced automation for even the most challenging assembly tasks, introducing pioneering processes and using tried-and-tested software control to link it all together.

This information has been sourced, reviewed and adapted from materials provided by ficonTEC Service GmbH.

For more information on this source, please visit ficonTEC Service GmbH.