Photonic devices used within high-tech applications are constantly increasing in terms of their complexity. More so, larger amounts of optical elements with different photonic properties must be integrated into increasingly small packages.

Machines from ficonTEC meet the definition of state-of-the-art mechatronics, incorporating sophisticated mechanical positioning/motion elements, electronics and instrumentation, all combined with effective, easy to use software tools.

Experience with hundreds of installed base machines and continued machine development has led to number product lines being developed. These lines are all extremely modular, well established and ideal for integration into new or existing systems. They offer excellent levels of performance and reproducibility, and therefore, lower cost-per-part and higher yield.

Continuous system development allows ficonTEC to stay ahead of the rapidly changing customer manufacturing requirements present in photonic component assembly.

I

I

Multi-DOF Precision Positioning and Alignment

Pioneering positioning systems working alongside machine vision guarantee adaptability with consistent high-precision alignment.

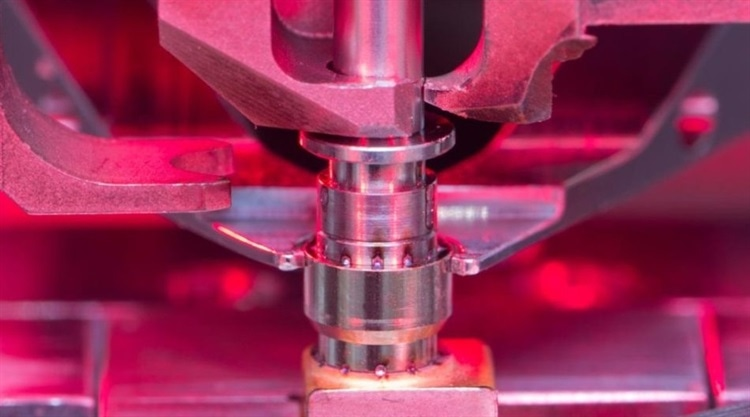

A major consideration in machine design is the importance of repeatable, accurate and reliable positioning of minuscule components over millions of cycles. The market’s best mechanical motion stages are accompanied with proprietary components, combining precision with industrial-grade robustness.

ficonTEC’s machines are regularly integrated with hexapod-like 6-DOF (degrees of freedom) devices, long-travel gantries, stacks of linear translation stages and goniometers, as well as SCARA and anthropomorphic robots.

State of the art, real time controllers enable rapid positioning interpolation for multi-axis systems with sophisticated capability, such as fast active alignment and pivot-point-based motion space.

Innovative machine vision algorithms coupled with multiple camera systems are linked to motion control, providing pre-alignment and guidance alongside other advanced functions. The motion-space and vision-space are correlated via automated geometric calibration processes.

Lastly, ficonTEC’s modular, versatile and user-friendly process programming software, Process Control Master (PCM), is employed to control the full range of hardware functions.

Bonding in Place

A range of bonding technologies are available, each designed to ensure reliable performance and long component lifetime.

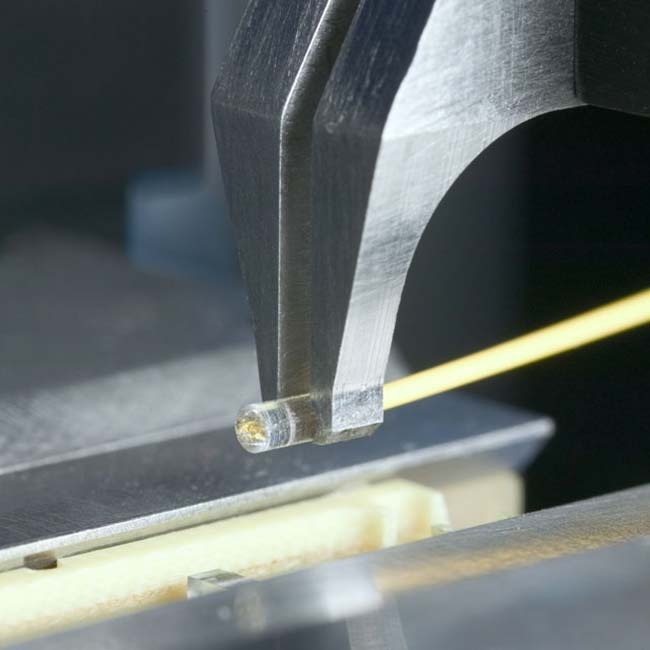

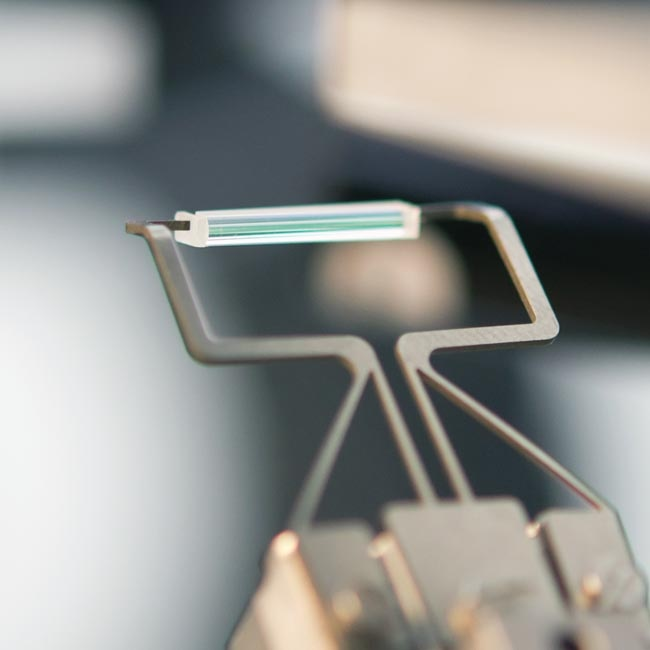

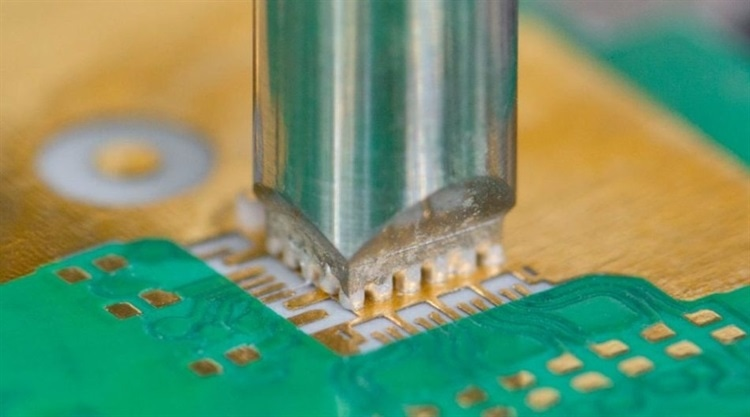

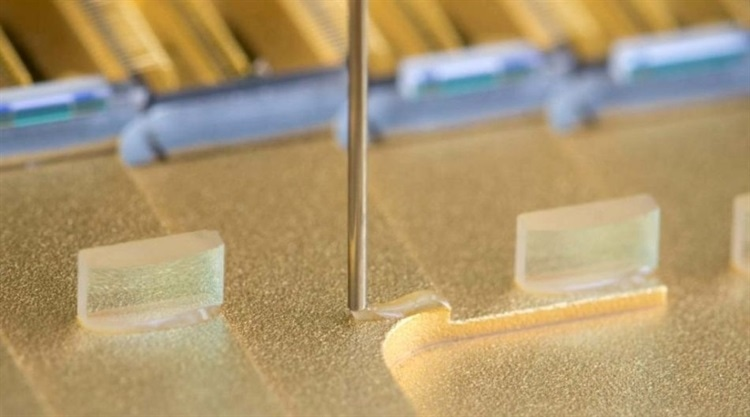

These bonding approaches are essential throughout the micro-assembly process. They include: UV and/or thermal-curing epoxy, laser welding, soldering and reflow processes, plus laser-induced soldering.

Common applications comprise bonding of photodiodes, LEDS, optical fibers, laser diode chips, micro-optical elements and lenses, etc. onto a substrate, a submount or, in some cases, onto a full photonics wafer.

Any automated means of choosing the bonding type must offer total control over the process. As such, it must achieve various tasks and goals:

- Controlled thermal cycles and/or thermal distribution, used for both soldering and laser-induced soldering

- Precise aim and focus of laser beams for laser welding

- Exact dispensing of various viscosity adhesives for epoxy bonding

- Appropriately distributed/timed UV flashing

- Precise pre-alignment re-positioning following dispensing

ficonTEC provides a number of recognized die bonder systems, ideal for a whole range of photonics micro-assembly tasks.

Welding

Soldering

(UV) epoxy dispensing

Combining Optical and Electrical Testing

ficonTEC’s testing systems are designed for the automated measuring and testing of photonic devices, ranging from single chips, right through to wafer level.

Generally, some sort of testing at the ‘packaged device’ or ‘single die’ stage has always been incorporated in ficonTEC manufacturing equipment as a required step within an assembly process. However, automated testing machines very much come into their own as volumes in photonics manufacturing continue to increase.

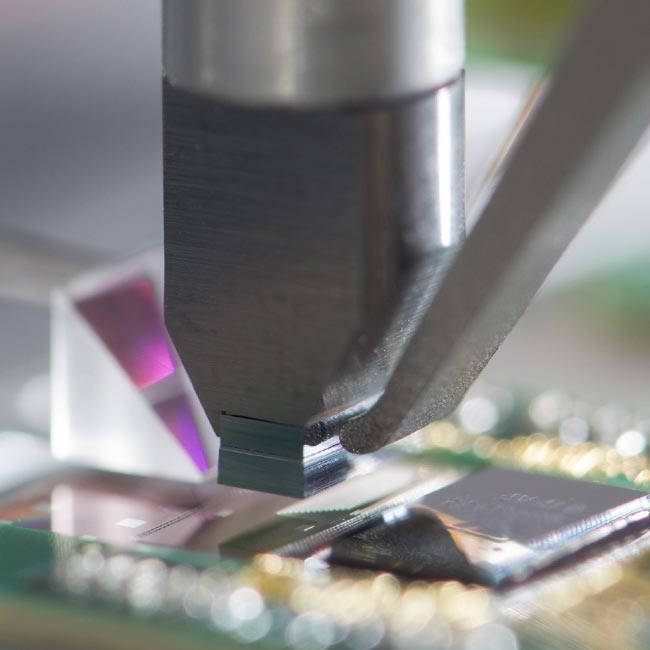

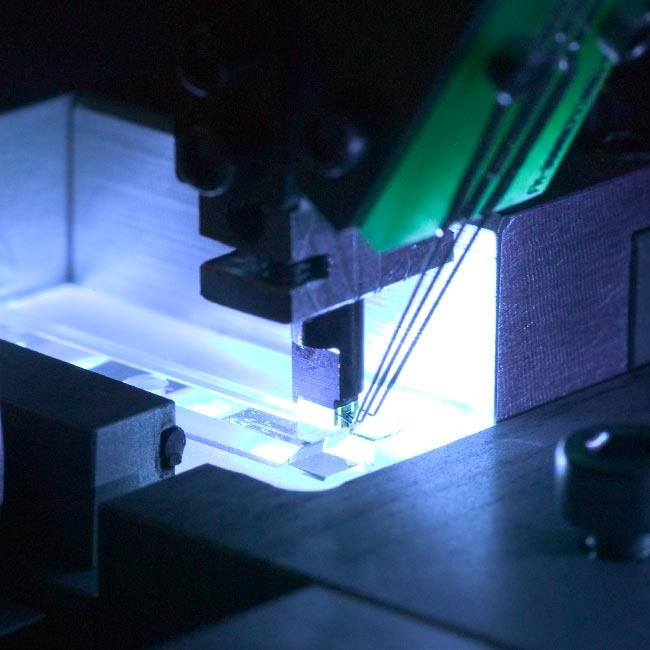

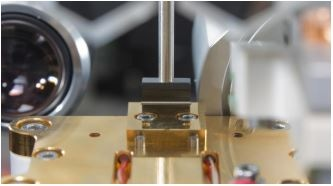

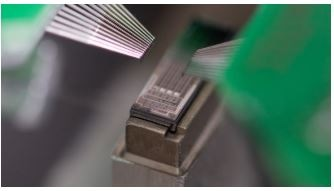

A clear trend towards full wafer-level photonics testing is also evident. Wafer-level testing via probe cards which hold several thousand pins are commonplace within the semiconductor industry, with typical contact pads being 80 x 80 µm2. Optical probing however, involves far higher positional accuracies - in the submicron range – and must employ edge coupling or vertically accessible grating couplers. The former of these two can be far more challenging at wafer-level.

As both electrical and optical probing are needed to test photonic devices, an integrated approach is required. This has led to the development of combined optical-electrical probe heads, with common tests including temperature dependence measurements, optical power insertion losses, spectral measurements, and electrical/optical bandwidth, among others.

Demands on modular instrumentation will continue to increase as the quantity of optical channels for simultaneous testing rises. This will include tunable laser sources, multi-channel power meters, optical switches, etc.

Automated testing protocols and sequences will also benefit from the use of the versatile Process Control Master software. Process tracking data being directly linked to an SQL database can provide users with access to statistical analysis of any recorded data, for example to improve production yield.

This information has been sourced, reviewed and adapted from materials provided by ficonTEC Service GmbH.

For more information on this source, please visit ficonTEC Service GmbH.