Bioprinting is an additive manufacturing (AM) method for producing biological materials that can be used in medicine, as well as other industries. In the latest advance in this relatively new field, researchers have developed a new microbial ink (ink made from bacteria) that deploys microbes as miniature factories for bioprinting applications.

Image Credit: Ladanifer/Shutterstock.com

What is Bioprinting?

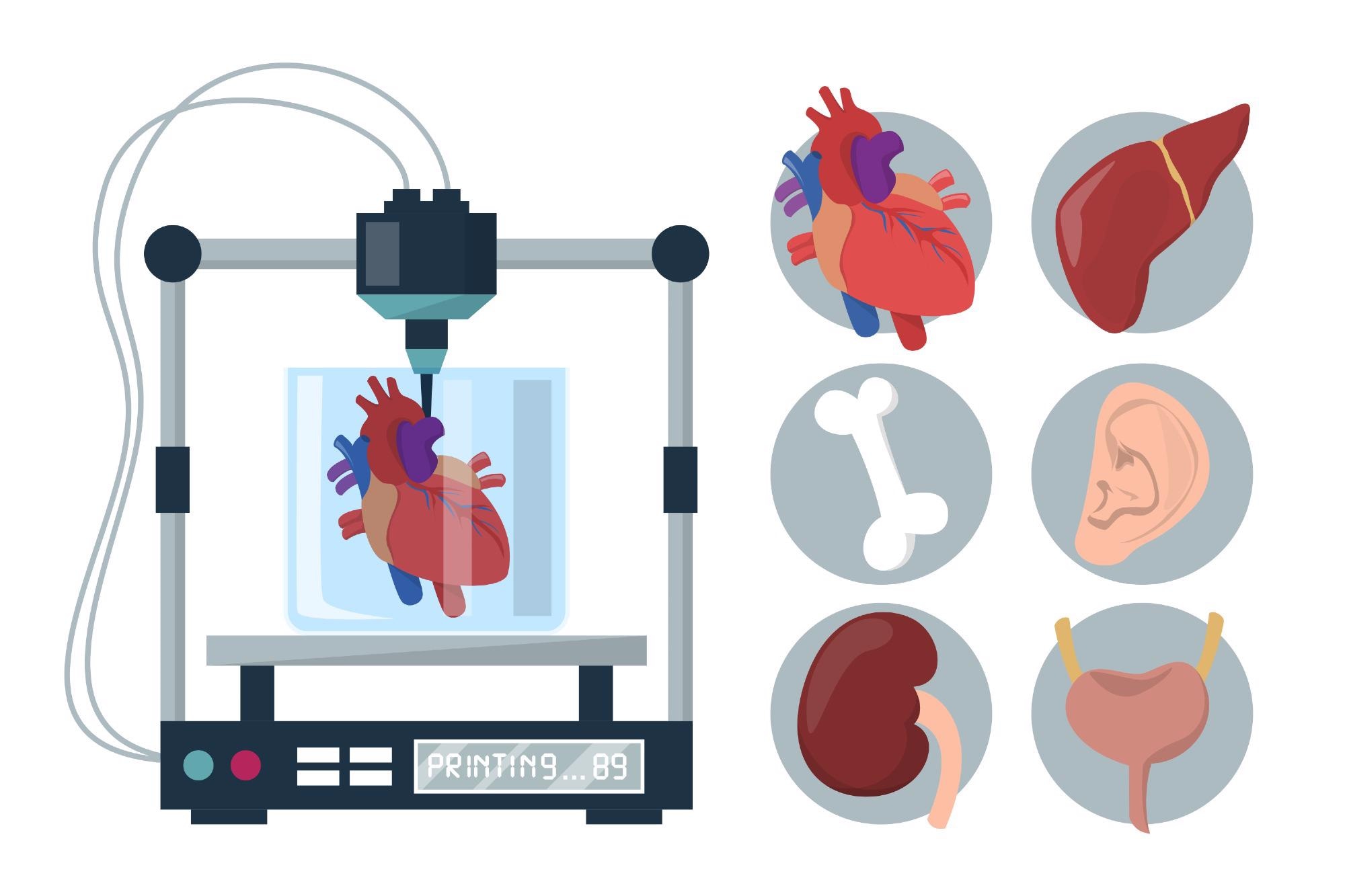

Bioprinting in three dimensions uses AM techniques (depositing a material layer on layer, rather than subtracting material from raw stock to make new products or parts) to produce biomedical parts. Biological organisms are utilized to combine cells, limit or enhance growth factors, and imitate the characteristics of natural tissues.

Bioprinting is widely applied in medicine today. It is used to print tissues and whole organs that pharmaceutical companies use to test new medicines on, replacing inaccurate, harmful, and often useless non-human animal testing. It can also print scaffolds that bodies will accept, enabling the regeneration of joints and ligaments.

New Microbial Ink

Now, researchers have started to modify the bacteria they use to make them more productive as tiny factories in bioprinting applications. Researchers based at Harvard University (United States) recently developed a novel microbial ink for bioprinting.

The research was led by bioengineers Anna Duraj-Thatte and Avinash Manjula-Basavanna and was published in the journal Nature Communications.

The Harvard team started with E. coli, a common bacteria. They changed the E. coli genes so that protein fibers emitted by the bacteria as structural support could be modified.

Tuning the E. coli genes led to the bacteria creating different shapes with their structural support. The group referred to these shapes as “knobs” and “holes.” Differently modified microbes would form knobs or holes, and growing these together resulted in both types of protein fiber being made.

Further Reading: Producing Biofilms with Additive Manufacturing

When grown together, the different types of fiber structure linked up, with knobs filling holes and the resulting viscous mixture becoming stiffer. Researchers filtered this mixture to remove the bacteria and the nutrients included to feed them.

The remaining material containing protein fibers only is a hydrogel (a wet gel). The team found that this hydrogel was a suitable candidate for 3D printing, having a consistency similar to toothpaste being squeezed out of a tube.

The team took their breakthrough a step further by adding microbes back into the hydrogel mix. These new bacteria were programmed to make cancer-treating drugs or clean up toxic chemicals in living cells.

The researchers found that the hydrogel mixture they developed is still not stiff enough for building solid objects. However, future research in this area is likely to unlock even stiffer microbe-based inks, enabling the technology to take off.

Applications for Bioprinting

There are numerous applications for bioprinting in medicine, and many of them are completely novel. For example, a baby with a rare disease called tracheobronchomalacia was given a 3D-printed tracheal splint to help them breathe. The technique is often used to refashion tissue in different parts of the body like this.

Image Credit: Derariad/Shutterstock.com

People who have end-stage bladder disease can be treated with bioprinted bladder tissues that build the organ up again. The same technology can be applied to bones, skin, cartilage, and muscles.

Tissue engineering is a new medical field that has been significantly advanced by the introduction of 3D bioprinting techniques. This is the field that develops new biomaterials as inks and substrates for bioprinting.

Sometimes, biomaterials are stronger than their naturally occurring alternatives, including bones and soft tissue. These materials can be substituted for diseased or damaged tissues in the body, and in the future may even help to enhance our biological processes.

Alginate is an example of a strong biomaterial. It is an anionic polymer that exhibits strong biocompatibility with human bodies, has low toxicity, is stronger than naturally occurring tissues, and can be feasibly produced at scale.

Interview: Alginate-Based 3D Printed Inks For Biomedical Models

The Future of Bioprinting

Bioengineers are currently researching methods of bioprinting micro-channels to ensure that nutrients and oxygen from neighboring tissues diffuse effectively along tissues.

In the future, whole organs could be fabricated with bioprinting. This would eliminate any cause for animal testing, which results in the often pointless death and suffering of animals.

Of course, producing a fully bioprinted organ would have an impact on the direct medical treatment of humans as well. This is now the focus of many bioengineers, but it has not been achieved as of yet. Organs are much more complex in shape and function than stents, having to work with electrical signals in the body and mechanical (changing) loads.

It seems likely that getting to this stage is only a matter of time. Once the technology to bioprint whole organs exists, it must then be developed to ensure its potential for improving health outcomes around the world is fully realized. This means ensuring that bioprinting hardware, inks, and substrate materials can be manufactured at scale, at relatively low prices, and around the world.

References and Further Reading

Duraj-Thatte, A. M. et al. (2021). Programmable microbial ink for 3D printing of living materials produced from genetically engineered protein nanofibers. Nature Communications. Available at: https://www.nature.com/articles/s41467-021-26791-x

Roche, C. D. et al. (2020). Current challenges in three-dimensional bioprinting heart tissues for cardiac surgery. European Journal of Cardio-Thoracic Surgery. Available at: https://academic.oup.com/ejcts/article/58/3/500/5835731

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.