Interview conducted by Lexie CornerJul 9 2025

Interview conducted by Lexie CornerJul 9 2025The battery passport is designed to improve traceability and support consistent reporting on sourcing, production, and environmental impact. With the EU Batteries Regulation setting a clear framework, manufacturers and suppliers are beginning to align their operations accordingly.

To explore how this innovation is taking shape and what it means for industry, we spoke with Dominique Scheider, who leads Industry Strategy Marketing for the Transportation sector at Rockwell Automation in EMEA.

To start, could you introduce yourself and your role at Rockwell Automation?

My name is Dominique Scheider, and I lead Industry Strategy Marketing for the Transportation sector across the Europe, Middle East, and Africa (EMEA) region at Rockwell Automation.

My focus is helping automotive and energy storage manufacturers navigate complex transitions toward digitalization, sustainability, and regulatory compliance through our technology portfolio and PartnerNetwork ecosystem.

For readers who may not be familiar, can you give us an overview of Rockwell Automation’s role in the battery manufacturing space?

Rockwell Automation provides advanced industrial automation and digital transformation technologies that underpin battery production, from raw material handling to cell assembly and pack testing.

Our solutions ensure greater operational efficiency, real-time quality management, and now, with tools like the Digital Battery Passport, robust traceability and compliance support. We work with OEMs to build sustainable, transparent supply chains aligned with the energy transition.

One of the key innovations you showcased at The Battery Show Europe this year is the Digital Battery Passport. What is its primary purpose, and what kinds of supply chain challenges is it intended to help manufacturers solve?

The Digital Battery Passport solution, developed by our Partners Circulor, a UK-based technology company founded in 2017 that specializes in supply chain traceability, creates a secure, end-to-end digital thread across the battery lifecycle, from raw material extraction to recycling. It ensures full traceability of high-risk materials such as lithium and cobalt, allowing manufacturers and regulators to verify the origin and journey of these materials.

Secondly, the passport supports compliance with increasingly stringent regulations, particularly the European Union’s Battery Regulation, which mandates transparency and sustainability reporting across the value chain and the EU Green Deal, particularly in its push toward a circular economy and climate neutrality by 2050.

Additionally, it provides a mechanism for tracking carbon emissions, labour standards, and broader ethical considerations, thereby enabling manufacturers to validate their sustainability claims. By creating a unified, verifiable source of supply chain data, the passport promotes greater transparency and accountability among all stakeholders. This not only helps manufacturers improve sourcing strategies but also provides a competitive edge by meeting growing expectations from consumers, investors, and regulators for responsible and sustainable practices.

As regulatory and consumer pressures for transparency continue to rise, traceability is no longer a nice-to-have; it’s a necessity. The Digital Battery Passport is more than just a compliance tool; it's a catalyst for transparency and sustainability. By giving manufacturers near real-time insights into material provenance, carbon footprint, and lifecycle data, we're helping them tackle some of the toughest challenges in the battery supply chain, from ethical sourcing to circularity and regulatory readiness.

Douglas Johnson-Poensgen, Founder and President at Circulor

Can you walk us through a real-world example of how the Digital Battery Passport enables traceability?

The Digital Battery Passport enables traceability of upstream materials like lithium and collates data at every stage of the battery's lifecycle. The process begins at the mine, where lithium is extracted and assigned a digital identity that includes its origin, and materials flow through the supply chain as well as the environmental impact.

As the lithium moves through refining and processing facilities, the Digital Battery Passport is updated with information about chemical transformations, energy usage, and emissions. This ensures that each batch of lithium can be traced back to its source, with a verifiable record of its environmental and social footprint.

Once the lithium is integrated into active materials and assembled into battery cells at gigafactories, the Digital Battery Passport continues to track its journey. It records technical specifications, certifications, and links to other materials used in the battery. When the battery is put into service, the passport is updated with relevant details such as the activation date and warranty period, and made accessible via a QR code or digital interface.

This end-to-end traceability helps manufacturers comply with EU regulations, manage ESG risks, and support circular economy goals by enabling efficient recycling and second-life applications.

You’re collaborating with Circulor on the deployment / implementation of the Digital Battery Passport. How does Circulor’s technology integrate with Rockwell’s digital manufacturing platforms? And more broadly, how do partnerships extend the value of your solutions across the energy ecosystem?

Circulor’s technology integrates seamlessly with Rockwell Automation’s digital manufacturing platforms to provide comprehensive solutions.

Circulor contributes to a blockchain-based platform that captures and secures data across the entire battery supply chain, ensuring each stage, from raw material extraction to battery assembly, is recorded with transparency and integrity. This data is then synchronized with Rockwell’s industrial automation systems, enabling real-time insights and end-to-end visibility within a unified digital thread.

This collaboration allows manufacturers to not only track material provenance but also monitor emissions, labour conditions, and regulatory compliance metrics in a secure and verifiable manner.

Crucially, Rockwell ensures the operationalization of the Digital Battery Passport by connecting it directly to shop-floor systems and dispersed industrial assets. Our digital services ensure deployment across all layers of the enterprise, from sensors and machinery on the plant floor to corporate sustainability reporting tools, so that the passport is embedded into both operations and decision-making processes.

More broadly, partnerships like the one between Rockwell and Circulor extend the value of digital solutions across the energy ecosystem by connecting operational technology (OT) with supply chain data. These alliances help manufacturers future-proof their operations, achieve sustainability goals, and respond more effectively to evolving industry demands.

Douglas Johnson-Poensgen, President at Circulor, said: “Our mission at Circulor is to bring unseen operations into clear view by delivering traceability and proof of provenance across complex industrial supply chains. Partnering with Rockwell Automation enables us to embed that traceability directly into the manufacturing production process. Together, we're not only supporting compliance with regulations like the EU Battery Regulation, but we’re also empowering manufacturers to build trust, drive sustainability, and operate more responsibly at scale.”

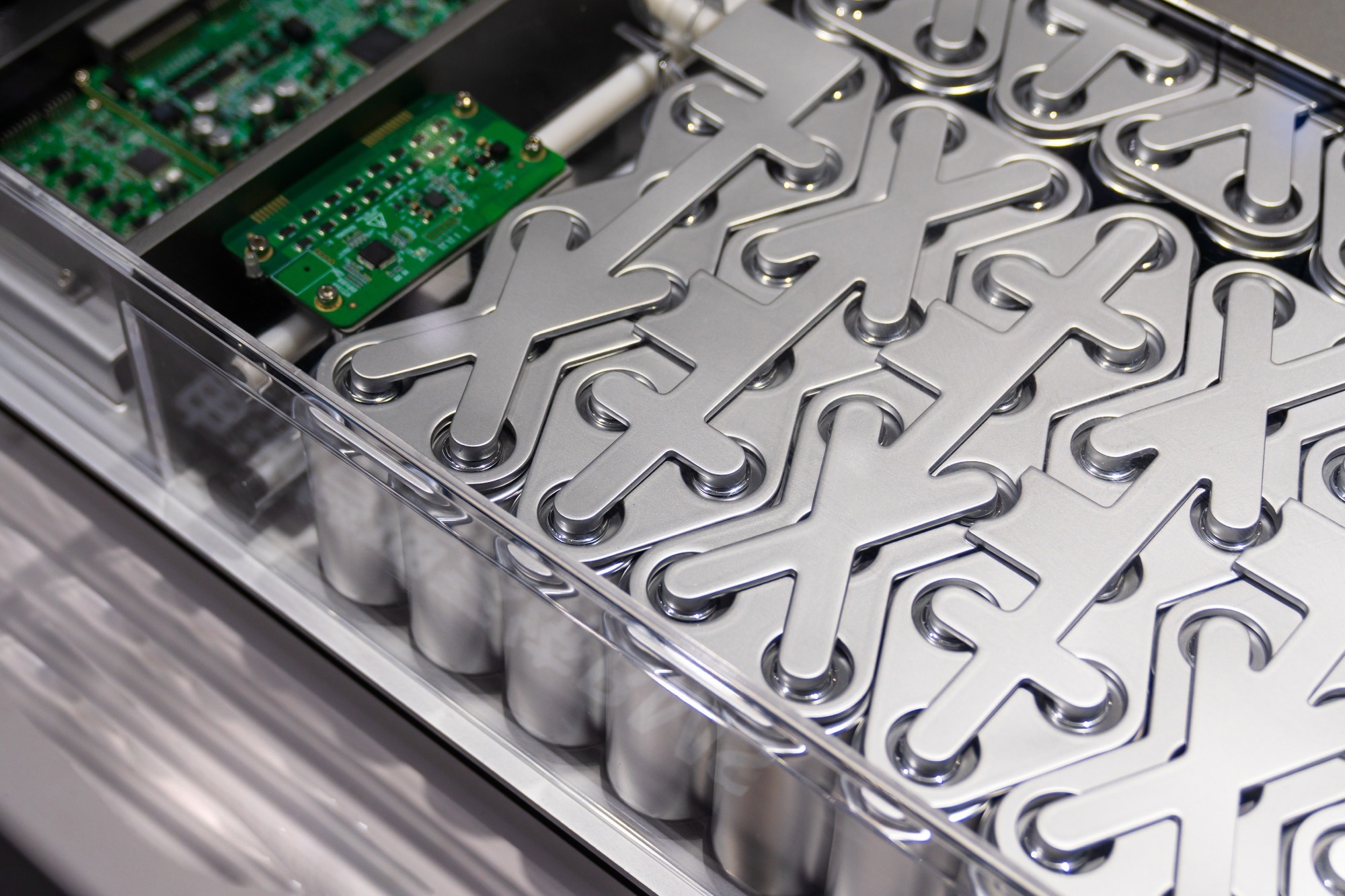

Image Credit: THINK A/Shutterstock.com

With the upcoming EU Battery Regulation mandating lifecycle transparency and sustainability disclosures, how are your customers using the Digital Battery Passport to prepare for (or even get ahead of) these compliance requirements?

Customers are leveraging the Digital Battery Passport as a strategic tool to proactively align with the EU Battery Regulation, which requires lifecycle transparency and sustainability reporting.

By using the passport, manufacturers can systematically collect and validate data on material origin, carbon footprint, logistics, and end-of-life processing, all in a secure format. This not only simplifies compliance reporting but also enhances audit readiness and risk mitigation.

The Digital Battery Passport enables companies to centralize complex supply chain documentation, making it easier to prove due diligence and meet ethical sourcing standards. Furthermore, by implementing these capabilities early, our customers are not just complying with regulations; they’re gaining a competitive edge by building transparency and trust with regulators, partners, and eco-conscious consumers.

Through Circulor’s PROVE platform, manufacturers can now demonstrate the use of recycled materials in battery production, a key requirement of the EU Regulation. This additional functionality enhances the Digital Battery Passport’s role in helping manufacturers validate sustainability claims and accelerate circular economy goals.

During the event, you’re also launching the State of Smart Manufacturing Report – Automotive Edition. Are there any standout findings from this year’s report that are especially relevant to battery manufacturers or the broader energy transition?

The 2025 State of Smart Manufacturing – Automotive Edition highlights several critical trends that are especially relevant for battery manufacturers. The report shows that 95 % of automotive, tire, and battery manufacturers are either investing in or planning to invest in AI technologies over the next five years. These investments are being driven largely by the need to overcome external pressures such as inflation, workforce pressures, and evolving regulatory requirements.

Another key insight is that only 5 % of respondents in the sector report using more than 75 % of their collected data effectively, indicating significant room for improvement in digital maturity. Meanwhile, 42 % of manufacturers are turning to automation and AI/ML to address labour shortages, while 36 % are investing in technologies to make roles more engaging for existing employees.

These findings reinforce the importance of solutions like the Digital Battery Passport. Together, they reflect a broader shift toward smarter, more sustainable, and technology-driven manufacturing models that are critical to supporting the energy transition.

Looking ahead, what emerging technologies or challenges in energy storage is Rockwell Automation focused on, and how are you evolving your solutions to meet them?

Rockwell Automation is actively focused on addressing several emerging challenges in the energy storage sector, including the need for safer battery chemistries, improved supply chain transparency, and advanced digitalization of manufacturing environments.

This proactive approach is also reflected in our recent partnership with Enerpoly, a company that is pioneering zinc-ion battery technology as a safer, more sustainable alternative to traditional chemistries. By working together on zinc-ion battery manufacturing, we’re helping to commercialize a non-lithium alternative that reduces reliance on scarce or high-risk materials, while still delivering high performance.

In parallel, we're advancing digital traceability to address regulatory and supply chain transparency challenges. Circulor and Rockwell Automation were selected by Acculon Energy to implement the Digital Battery Passport at Acculon’s Ohio-based facility, enabling full traceability of critical battery materials like lithium, cobalt, nickel, and graphite.

This collaboration integrates Circulor’s blockchain-based traceability platform with Rockwell’s digital manufacturing systems to track material provenance, carbon emissions, and compliance data from cell selection through to final battery production. The project supports Acculon’s commitment to sustainability and regulatory readiness, particularly in meeting the EU Battery Regulation, while also enhancing transparency and accountability across the commercial and industrial battery supply chain.

Collaborations like this reinforce the broader mission of the passport, which is to drive responsible innovation while ensuring full visibility across emerging energy storage ecosystems.

At the same time, we continue to evolve our automation, AI, and data analytics platforms to ensure that energy storage manufacturers can scale their operations efficiently and responsibly. From deploying blockchain-enabled traceability tools like the Digital Battery Passport to integrating generative AI into quality control and process optimization, Rockwell Automation is enabling a more resilient and future-ready battery ecosystem.

About Dominique Scheider

With over 30 years of experience across the automotive and tire industry, including car manufacturers and Tier-1 suppliers, Dominique Scheider is responsible for defining the EMEA strategy for the transportation industry at Rockwell Automation.

By developing executive-level partnerships and identifying mutually beneficial business opportunities, Dominique supports business growth across the transportation manufacturing portfolio.

Prior to his current position, Dominique held global and EMEA-based sales management roles.

Before joining Rockwell in 2006, Dominique worked for two multi-national companies focusing on robotics integration within heavy industries.

Where can readers find more information?

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.