Slicer software acts as a crucial intermediary in the 3D printing process, bridging the gap between intricate digital designs and physical objects. By converting complex blueprints into optimized instructions for the printer, slicer software empowers users with precise control over printing parameters, resulting in enhanced print quality and a seamless printing experience. This article explores the significance and role of slicer software in enabling the transformation of digital blueprints into tangible creations.

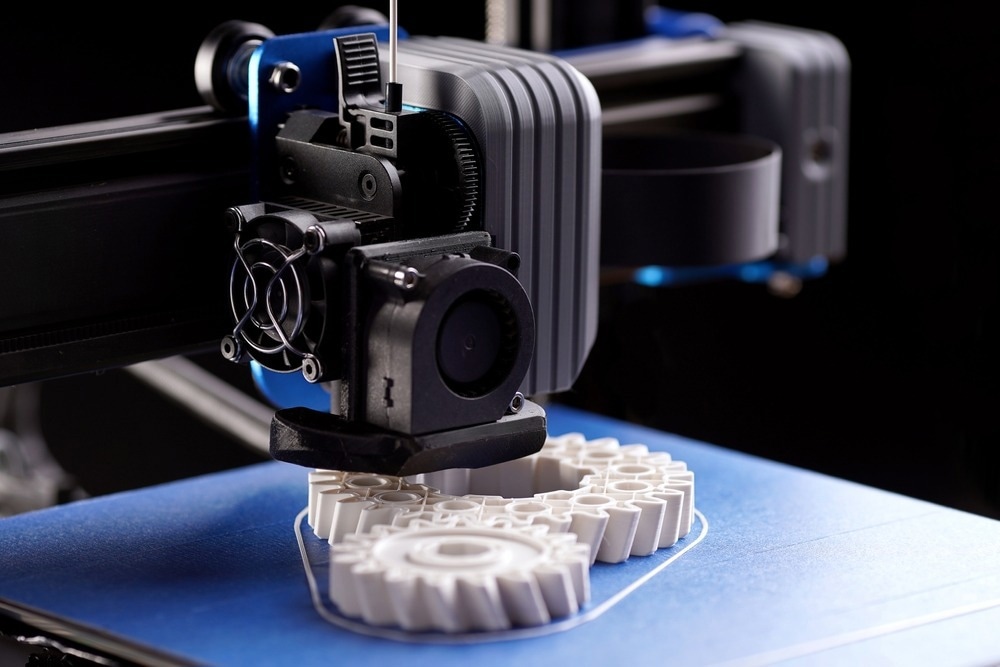

Image Credit: R_Boe/Shutterstock.com

What Is Slicer Software and How Does it Enable 3D Printing?

3D printing, a type of additive manufacturing, works by creating objects layer-by-layer based on a digital computer-aided design (CAD) model. It has revolutionized design and manufacturing processes, offering a cost-effective, fast, and efficient prototype production approach.

While the 3D printer provides physical tools like the print head and material, it cannot directly use a 3D model file. This is where slicer software becomes essential. It acts as the bridge between the digital CAD model and the physical printing process.

Slicer software converts the 3D model file into printing instructions, called G-code, for a 3D printer to create the required object. The accurate conversion from a CAD model to G-code is critical to ensure that the final output aligns with the intended design and specifications, making the selection of the appropriate slicer software paramount in achieving successful and high-quality 3D prints.

Components of a Slicer Software

Slicer software can be divided into two main components: the front-end user interface and the back-end logic.

Front End

The front end of a slicer software provides the graphical user interface (GUI) that allows users to interact with and control the 3D model and slicing process. It provides user-friendly tools and features to customize the model, such as print speed, layer height, and temperature.

It also offers visualizations like layer views and toolpath previews generated by the back-end algorithms.

Back End

The back end of the slicer software handles several key tasks, such as analyzing the STL file, slicing the model into layers, determining the optimal tool path for printing, and generating the G-code instructions.

The most important component is the G-code, containing optimized commands (e.g., "G" for motions and extrusion, "M" for miscellaneous functions) that guide the 3D printer during printing.

Each line of G-code describes specific movements and actions for the print head and build plate. Understanding the G-code is valuable for troubleshooting and achieving successful 3D prints.

How 3D Slicer Software Works?

The workflow of slicer software typically involves several key steps:

- The printer settings are configured, specifying parameters like nozzle size and filament type.

- The 3D model file, usually in STL format, is imported into the software.

- The model is then oriented and positioned on the virtual print bed to ensure optimal placement.

- Key settings such as layer height, infill density, speed, and temperature are set according to the desired outcome.

- The software slices the model into horizontal cross-sections based on the specified layer height, essentially dividing it into printable layers.

- Optimal tool paths are generated, outlining the movement of the print head for each layer.

- Additional structures, such as supports and brims, are added based on user settings to enhance stability during printing.

- Users visualize the layers and toolpaths to verify the slicing result before proceeding.

- Finally, the software exports the final instructions as a G-code file.

Benefits of Using Slicer Software

Customization

A key benefit of slicer software is its ability to easily customize prints through settings like wall thickness, print speed, and infill density. This enables users to optimize prints according to their requirements, balancing tradeoffs between quality, time, and material usage.

Cost and Waste Reduction

By specifying the design parameters and material usage settings, slicer software helps reduce costs by minimizing material waste and optimizing the overall design.

Material Planning and Print Time Estimation

The slicer software informs users about the total material volume and estimated print time required before starting a print. This allows better planning and resource allocation.

What Are the Key Attributes of An Ideal Slicer Software for Reliable 3D Printing?

When evaluating slicer software, ease of use should be considered to ensure the features are accessible. In addition, slicer software should provide accurate previews for estimating printing time and material usage while offering visualization tools such as layer and path previews to verify the slicing result.

A good slicer software should allow quick importing of STL files regardless of complexity and provide model repair tools to fix errors. Automatic generation of supports is another desirable quality in slicer software, as it ensures precision and accuracy, especially for challenging angles.

Free slicer software options like PrusaSlicer, Cura, and SuperSlicer provide excellent functionality and compatibility with a wide range of 3D printers. However, a paid slicer such as Netfabb or Simplify 3D offers substantial advantages and additional features that justify the investment.

Therefore, an ideal slicer software should have an intuitive interface with robust tools for importing, optimizing, visualizing, and repairing 3D models to ensure reliable printing. Prioritizing usability, adaptability, and functionality helps choose a slicer software that can handle diverse printing needs.

More from AZoM: SLA vs. FDM 3D Printing: What to Know

References and Further Reading

Bryła, J., & Martowicz, A. (2021). Study on the importance of a slicer selection for the 3d printing process parameters via the investigation of g-code readings. Machines, 9(8), 163. https://doi.org/10.3390/machines9080163

Cavitar. (2023). The ABC of Additive Manufacturing. AZoM. Retrieved on July 09, 2023, from https://www.azom.com/article.aspx?ArticleID=22145

Ekaran, S. (2022). What Is 3D Slicing and Why Is It Important? [Online]. Retrieved on July 09, 2023, from https://www.makeuseof.com/3d-slicing-why-important-3d-printing/

Kolla, M. (2021). What is the role of Slicing in 3D printing? [Online]. Retrieved on July 09, 2023, from https://fabheads.com/blogs/what-is-the-role-of-slicing-in-3d-printing/

Solid Print. (2023). 3D Slicer Software: How it Works and What to Expect. [Online]. Retrieved on July 09, 2023, from https://www.solidprint3d.co.uk/3d-slicer-software-how-it-works/

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.