In this interview, AZoMaterials speaks with METTLER TOLEDO's Larry Hale about innovations in measurement technology across the battery value chain.

Can you please introduce yourself and your role?

I’m Larry Hale with the Process Analytics Group at METTLER TOLEDO. My focus is on integrating pH, conductivity, and other key analytical tools across the battery manufacturing landscape to support quality, efficiency, and scalability.

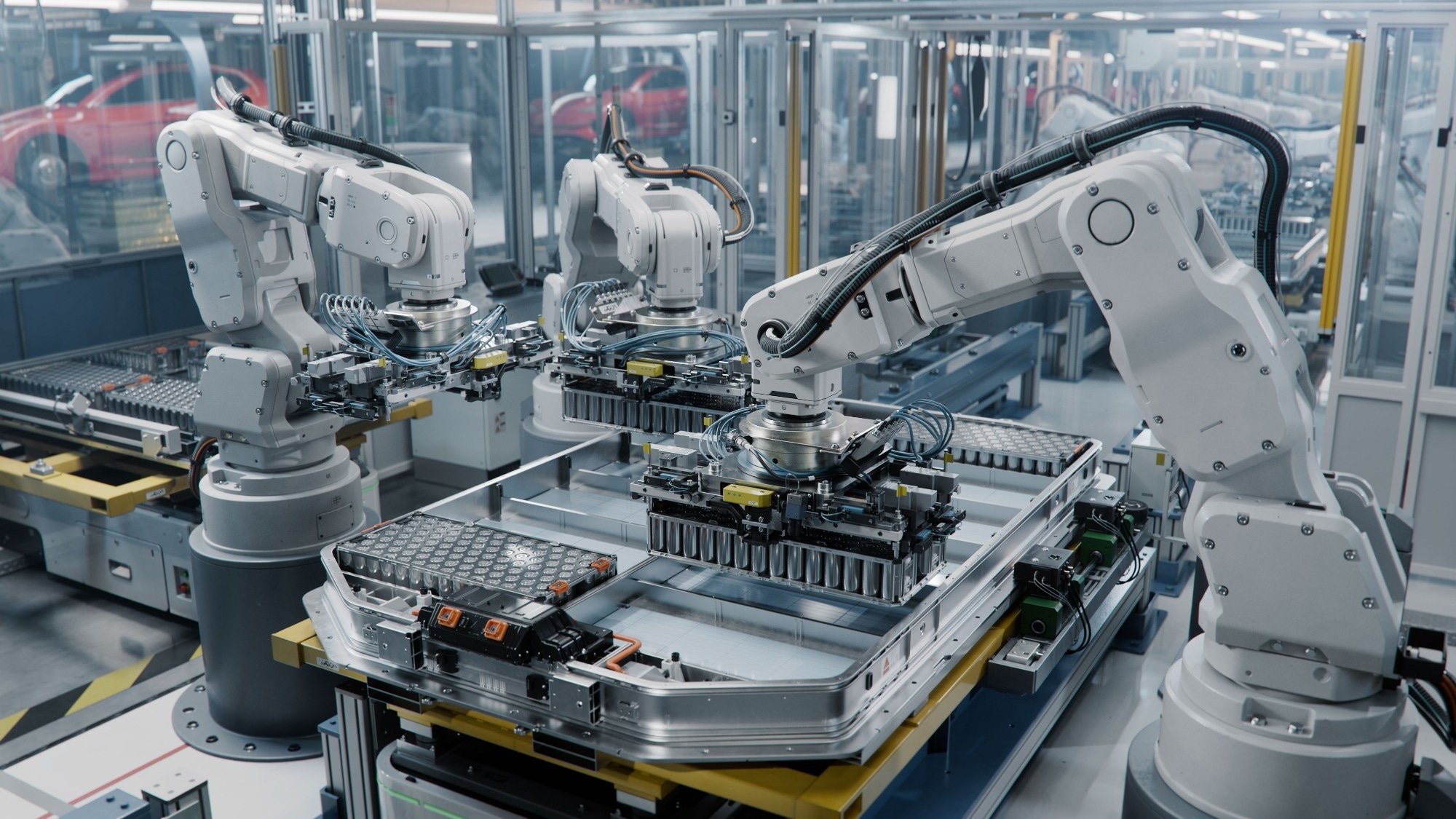

Image Credit: IM Imagery/Shutterstock.com

How do inline measurements compare to traditional lab measurements in battery manufacturing?

Inline systems bring the heat when it comes to speed and precision. Instead of waiting on lab results, manufacturers can make real-time decisions that help maintain product quality and consistency. Plus, with technologies like METTLER TOLEDO’s Intelligent Sensor Management (ISM™), inline sensors monitor their own health and performance, reducing guesswork and unnecessary recalibrations. It’s all about faster feedback loops and fewer process hiccups.

How does particle size measurement influence battery component performance?

Particle size and morphology are critical to the performance of cathode active materials (CAM) used in lithium-ion batteries. These properties are largely determined during the co-precipitation of precursor materials, such as nickel, cobalt, and manganese hydroxides (PCAM). pH plays a central role in controlling the nucleation and growth of particles in these reactions. Even slight deviations - as little as 0.1 pH units - can lead to substantial changes in particle size distribution and shape, which in turn affect battery efficiency, charging characteristics, and overall performance. Accurate and continuous pH control is therefore essential.

What role do zeta potential and pH measurement play in battery production?

One notable trend is the increasing focus on tailoring material properties through precise control of process variables, particularly during the synthesis of precursor materials. Dry powder electrode production benefits from advances in process analytics that enable more consistent particle morphology and distribution. Inline monitoring tools, such as robust pH sensors with solid polymer electrolytes, are increasingly being used to support these developments, ensuring greater consistency and efficiency during scale-up.

How is in-situ analysis transforming battery R&D?

In-situ analysis allows for real-time monitoring of key process parameters, providing researchers with immediate feedback during battery material development. This not only accelerates the research cycle but also improves the reliability of data used to inform scale-up decisions. By capturing dynamic process conditions as they occur, in-situ analysis bridges the gap between laboratory research and industrial application, supporting more effective technology transfer and optimization.

What are some of the latest trends in dry powder electrode manufacturing?

One notable trend is the increasing focus on tailoring material properties through precise control of process variables, particularly during the synthesis of precursor materials. Dry powder electrode production benefits from advances in process analytics that enable more consistent particle morphology and distribution. Inline monitoring tools, such as robust pH sensors with solid polymer electrolytes, are increasingly being used to support these developments, ensuring greater consistency and efficiency during scale-up.

How does automation enhance battery analytics?

Automation plays a critical role in enhancing both measurement reliability and operational efficiency. For example, METTLER TOLEDO’s EasyClean™ 200 e system automates the cleaning of pH sensors, which is particularly valuable in slurry-based processes such as PCAM production. This system periodically retracts the sensor for thorough cleaning and then returns it to the process, minimizing fouling and measurement drift. When combined with intelligent sensor technology, automated systems reduce maintenance workload and ensure that data remains accurate over extended production cycles.

What types of measurements are most important in pilot facilities to support process development and scale-up?

Key measurements in pilot-scale environments include pH, conductivity, and temperature, as these parameters directly influence reaction kinetics and material properties. Equally important is the scalability of the measurement technology itself. Data collected during pilot-scale trials must be transferable to full-scale production conditions to ensure continuity in process development. Utilizing robust, production-ready sensors from the outset helps maintain this continuity.

How are battery measurement techniques being applied to environmental or wastewater testing?

Many of the same analytical techniques used in battery production, particularly pH and conductivity monitoring, are directly applicable to wastewater treatment. The level of complexity in a given wastewater process will determine how advanced the measurement technologies need to be, but fundamentally, the measurement principles remain consistent. In fact, robust sensors developed for battery slurry processes often perform well in harsh environmental conditions, making them suitable for a range of industrial water treatment applications.

About Larry Hale

Larry Hale is a Regional Sales Manager at METTLER TOLEDO, and has worked at the company since 2009.

This information has been sourced, reviewed and adapted from materials provided by METTLER TOLEDO - Process Analytics.

For more information on this source, please visit METTLER TOLEDO - Process Analytics.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.