In this interview, AZoMaterials talks to Sandra Buechs, Head of Product Management, from Evonik about their vision in materials science for sustainable energy, focusing on how their new foam core material, ROHACRYL™, is revolutionizing wind turbine blade design.

Can you give us an overview of Evonik’s role in advancing materials for renewable energy applications, particularly in the wind energy sector?

Supporting the transition to sustainable energy is a key part of Evonik’s broader vision, and wind energy is one of the areas where our materials play an important role.

Wind turbines are a critical technology in the energy mix, providing consistent green power - even when solar energy isn’t available. But to operate effectively and efficiently, especially over decades, turbines need to be built with the right materials. This is especially true for rotor blades, which are getting longer and must remain as lightweight as possible. That’s why manufacturers often use glass fiber, carbon fiber, and foam composites in their designs.

To strengthen these composites, silanes like DYNASYLAN® are used to improve adhesion between the reinforcing fibers and the polymer matrix. This enhances both the structural integrity and durability of the blades, which is key for ensuring turbines can operate reliably for over 20 years with minimal maintenance.

Another important material is VESTAMIN® IPD, which is part of the curing agent system used in rotor blade production. It plays a key role in the reactivity and mechanical strength of the cured VARTM (Vacuum-Assisted Resin Transfer Molding) matrix. When combined with ANCAMIDE® curing agents in wind bond pastes, these products provide excellent adhesion, forming strong, reliable internal bonds within the blade.

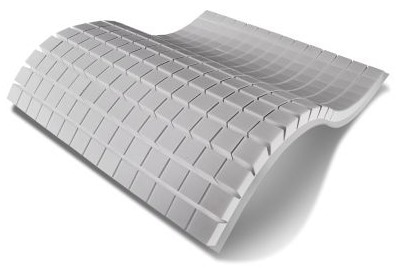

A more recent innovation is ROHACRYL™, our advanced foam core material. It offers strong mechanical performance at low weight, making it ideal for large blades. It’s also recyclable, contributing to circularity in manufacturing. With minimal resin uptake and low core density, ROHACRYL™ can help reduce the mass of finished parts, which may lead to significant cost savings and improved blade performance across the entire lifecycle.

Image Credit: Evonik Industries AG

ROHACRYL™ is a game-changing structural core material for wind turbine rotor blades. What are the key performance advantages it offers over traditional core materials?

ROHACRYL™ offers several key advantages over traditional core materials, starting with its ability to reduce overall blade mass and resin consumption. Its low density and fine, highly isotropic cell structure minimize resin uptake during the infusion process, which directly lowers material costs and results in lighter blades.

This weight reduction not only improves blade performance but also reduces the load on other turbine components, which is especially important for the increasingly long blades used in both onshore and offshore wind applications. ROHACRYL™ enables the production of high-quality blades at any length, meeting strict performance and durability standards that are difficult to achieve with conventional materials.

Additionally, ROHACRYL™ provides greater design flexibility. It supports a wide range of structural concepts and is compatible with automated production processes, helping engineers address specific manufacturing and performance requirements across different turbine platforms. This combination of lightweight performance, processing efficiency, and structural reliability gives manufacturers a clear edge in the competitive wind energy market.

Image Credit: wee dezign/Shutterstock.com

One highlighted benefit of ROHACRYL™ is its balance between strength, weight, and processing efficiency. Could you elaborate on how this impacts wind turbine blades' overall performance and lifecycle?

ROHACRYL™ offers a unique combination of mechanical strength and stiffness at low densities, which allows blade designers to create lighter, more efficient turbine blades without compromising structural integrity. Its highly isotropic cell structure is engineered for low resin absorption, helping reduce overall blade mass even further.

This reduction in weight has a direct impact on turbine performance and component longevity. Lighter blades place less stress on key structural parts, such as bearings, hubs, and towers, helping extend the overall lifespan of the turbine. This is especially important as onshore blades now routinely exceed 80 meters in length, and offshore blades can surpass 115 meters, with even longer designs in development.

In terms of manufacturing, ROHACRYL™ supports shorter cycle times thanks to its compatibility with automated handling systems and high processing temperatures. The closed-cell structure enables efficient handling, while the material’s excellent fatigue resistance contributes to long-term durability of the blade in demanding environments.

Altogether, the balance of performance, processability, and material efficiency makes ROHACRYL™ a valuable asset in improving both the operational and lifecycle performance of modern wind turbines.

Image Credit: Evonik Industries AG

How does ROHACRYL™ contribute to sustainability goals within the wind energy industry, especially in terms of energy efficiency and recyclability?

At Evonik, sustainability is a core focus, and ROHACRYL™ was developed with that in mind. It combines high performance with features that support circularity in the wind energy sector.

The material is based on a recyclable raw material platform, offering a lower carbon footprint and a cleaner end-of-life pathway. Its design helps reduce resin consumption during manufacturing, which lowers both material use and environmental impact. The lightweight structure also enables leaner blade designs and contributes to more energy-efficient turbines by reducing overall blade mass.

Additionally, ROHACRYL™ supports shorter cycle times in production, making the process more resource-efficient. Altogether, these benefits help manufacturers meet growing demands for responsible production while supporting the long-term sustainability of wind energy systems.

In terms of manufacturing, how does ROHACRYL™ integrate into existing production processes for wind turbine components? Are there notable advantages in terms of processing time or cost?

ROHACRYL™ integrates smoothly into existing kitting and lay-up processes, making it a practical choice for blade manufacturers. Its ease of machining allows it to be cut quickly and cleanly using standard CNC equipment, reducing preparation time on the shop floor.

The material’s high thermal stability supports faster cycle times in processes like vacuum-assisted resin infusion (VARI), leading to greater overall production efficiency. ROHACRYL™ is particularly well-suited for automated, high-volume manufacturing using RTM and infusion methods.

It can also be easily thermoformed, which allows for better fit in complex 2D and 3D curved areas, further reducing resin use compared to traditional deep-cut methods. With its combination of low density, excellent mechanical properties, low resin uptake, and compatibility with high processing temperatures, ROHACRYL™ addresses both design and manufacturing requirements efficiently, offering clear time and cost benefits across the production chain.

Image Credit: dragancfm/Shutterstock.com

The global demand for wind energy is accelerating. How is Evonik positioning its Performance Foams portfolio to support this industry's scaling and evolving needs?

Evonik’s Performance Foams team works closely with customers to develop tailored composite solutions that meet the demanding and evolving requirements of high-performance applications like wind turbine blades. Backed by Evonik’s global infrastructure, we’re well-equipped to support the wind industry as it scales.

For instance, ROHACRYL™ can be customized and delivered globally to align with the specific technical and supply chain needs of blade manufacturers, ensuring consistent quality and reliable support across key markets.

Could you share insights into how Evonik collaborates with wind turbine manufacturers or blade producers to co-develop customized material solutions?

The wind industry is facing several key challenges: faster installation, improved turbine efficiency, better performance, and the need to reduce waste and support circularity. In collaboration with wind turbine manufacturers and blade producers, we’re exploring how our next-generation core material, ROHACRYL™, can support both current and future blade designs by unlocking value at every stage of the blade lifecycle.

Evonik’s Performance Foams team works closely with customers to develop tailored composite solutions that meet evolving technical demands. Compared to commonly used core materials like PET and balsa, ROHACRYL™ offers a highly uniform, reproducible cell structure and a significantly better strength-to-weight ratio. This enables superior performance, reduces the risk of blade failure, and opens the door to next-generation blade designs that go beyond the limits of standard core materials.

Image Credit: Evonik Industries AG

Aside from wind turbine blades, are there other key application areas where ROHACRYL™ and Performance Foams from Evonik are making an impact?

Yes, while wind energy is a primary focus, Evonik’s Performance Foams portfolio supports a wide range of industries. For over 50 years, ROHACELL® has delivered proven performance in highly demanding composite structures - particularly in aerospace and space applications, where strength, precision, and weight reduction are critical.

ROHACRYL™, on the other hand, was developed to meet the needs of high-volume industries with a strong focus on lightweight design and sustainability. In addition to wind turbine blades, it’s increasingly relevant in sectors such as automotive, marine, industrial equipment, sports, and lifestyle products - where performance and efficiency must scale with production.

One recent example comes from Falcon Tenders, a British boatbuilder that used ROHACRYL™ to manufacture a rooftop component for a barge. The part was made 75 % lighter than specified, yet still strong enough to support 120 kg of panoramic glass. This project demonstrates the potential of sandwich construction in larger structures like electric boats and buses, where even modest weight savings can significantly impact energy efficiency and overall system performance.

Beyond structural performance, ROHACRYL™ supports sustainability goals. Its recyclable polymer design enables recovery and reuse at end-of-life, helping to close the material loop. This makes it a forward-looking solution not only for individual products, but also for improving the sustainability of entire manufacturing value chains.

Where can our readers find more information?

Performance foams for all your applications and processes - Evonik Industries

ROHACRYL™ reduces turbine loads - Evonik Industries

ROHACRYL™ Recyclable Foam for Lightweight Applications - Evonik Industries

ROHACRYL™ first ever marine application - Evonik Industries

About Sandra Buechs

Sandra Buechs is responsible for the product launch of ROHACRYL™ within Evonik Performance Foams. She studied Business Administration and holds an MBA. Over the course of her 20-year career, she has held different roles in management and business, working across both Europe and Asia.

About Evonik

Evonik goes beyond the boundaries of chemistry with its combination of innovative strength and leading technological expertise. The global chemical company, headquartered in Essen, Germany, is active in more than 100 countries and generated sales of €15.2 billion and earnings (adjusted EBITDA) of €2.1 billion in 2024. The common motivation of the approximately 32,000 employees: to provide customers with a decisive competitive advantage with tailor-made products and solutions as a superforce for industry, thereby improving people's lives. In all markets. Every day.

This information has been sourced, reviewed and adapted from materials provided by Evonik Industries AG.

For more information on this source, please visit Evonik Industries AG.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.