Nov 7 2009

Umomos / Shutterstock

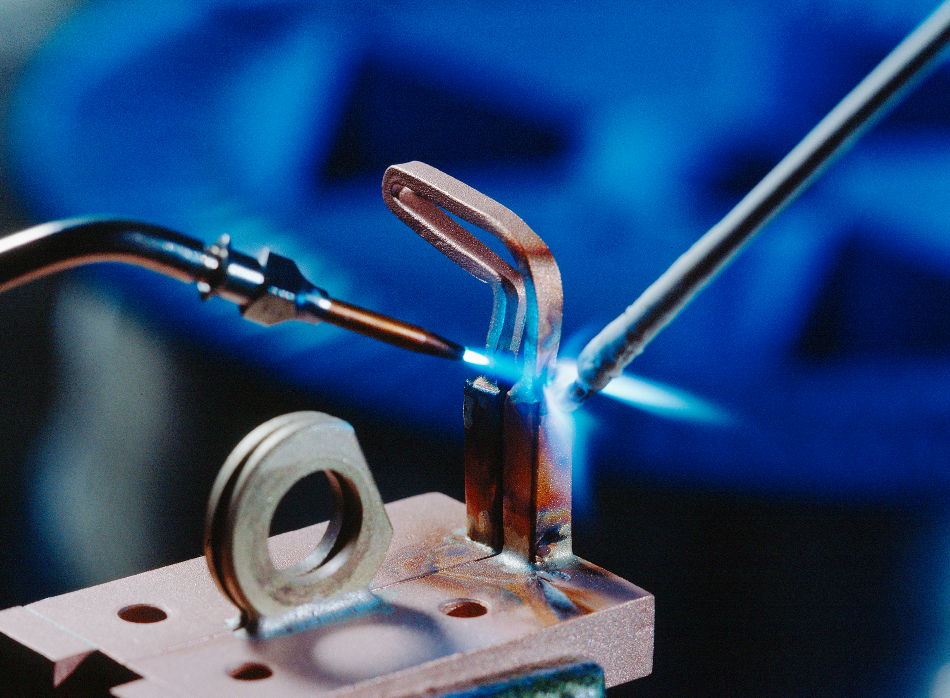

Gold-Based Industrial Brazing Alloys

Industrial brazing makes use of gold-based brazing alloys. When compared to base metal alloys, gold-based brazing alloys ensure good mechanical properties of joints at very high temperatures, have excellent corrosion resistance, and exhibit enhanced resistance to oxidation in demanding environments. However, these alloys are costly, and hence their use is limited in high-value applications.

Gold Brazing Alloys Used in Space Shuttle Engines

Alloys contain nickel-gold alloys of around 20 wt % gold, while the rest is made up of silicon, chromium, and iron. Alloys are used in the assembly of space shuttle engines and provide an alternative to traditional nickel-based brazing alloys.

Gold-Palladium Brazing Alloys

When palladium is added to gold alloys, they develop more resistance to oxidation at high temperatures and also gain increased strength. These materials are mostly used for combining metal components and superalloys that need to function in relatively challenging environments, for example, jet engines. The melting temperatures of these alloys can reach up to1200 °C.