The AVE3 sets the standard for extensometer performance, offering unmatched versatility and micron-level accuracy for tensile, compression, and bend testing. With precision strain measurement down to 1 micron, it’s designed to handle a wide range of applications - from small to large gauge lengths, low to high elongations, and everything in between.

Engineered for maximum flexibility, the AVE3 is ideal for testing delicate materials like thin films, managing explosive composite failures, and performing non-ambient tests with environmental chambers or fluid baths.

It is fully compliant with ISO 9513 and ASTM E83, ensuring that users can meet virtually any testing standard with a single device, eliminating the complexity and cost of managing multiple clip-on extensometers.

Instron® AVE3 Advanced Video Extensometer

Video Credit: Instron - USA

Download the Brochure for More Information

Designed for Accuracy

Eliminate Environmental and Operator Influences on Results

Image Credit: Instron - USA

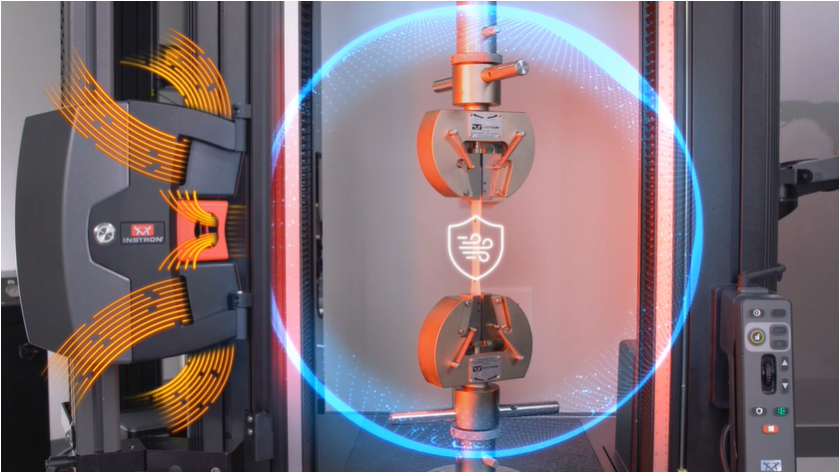

CDAT Airflow Technology Patent Pending

It should be noted that everyday environmental conditions in your lab can significantly affect your testing accuracy. In fact, thermal and air disturbances can reduce device performance by up to fivefold compared to ideal lab conditions. These issues often stem from routine lab activity - people walking by, nearby conversations, or even the HVAC system kicking on.

Instron’s AVE3 addresses this challenge with its patent-pending Constant Density Air Tunnel (CDAT) airflow technology. CDAT creates a stable shield around the test space, minimizing thermal and environmental interference. The result? Consistently accurate, repeatable results - regardless of what's happening around your setup.

Non-Contacting Solution

Image Credit: Instron - USA

The AVE3 removes the variability introduced by manual attachment, delivering more consistent and repeatable strain data. Its non-contact measurement approach eliminates the need for clipping devices on and off, streamlining your workflow and protecting specimens from premature damage caused by knife edges. The result is improved accuracy, reduced handling time, and optimized testing throughput - without compromising data quality.

Dynamic Cross-Polarized Lighting Patented

Image Credit: Instron - USA

Lighting conditions vary from lab to lab - and even throughout the day - which can introduce inconsistencies in test results. To eliminate this source of variability, the AVE3 is equipped with Instron’s patented cross-polarized lighting system.

This system dynamically adjusts to changing lighting conditions, ensuring your specimen markings are consistently and evenly illuminated. The result is reliable, repeatable measurements test after test, regardless of your lab’s environment.

One Device Endless Applications

Image Credit: Instron - USA

The AVE3 is designed to measure both modulus and strain to failure across a wide range of applications, including static tensile, flexure, and compression testing for both flat and round specimens. It performs reliably under ambient conditions and in challenging environments such as high or low temperatures, thanks to its compatibility with environmental chambers and fluid baths.

Whether you're working with plastics, metals, composites, textiles, films, foils, elastomers, paper, components, or biomaterials, the AVE3 delivers the versatility needed to support evolving testing requirements while meeting a broad range of industry standards.

Metal Standards

- ISO 6892, ASTM E8, JIS Z 2241, GB 228.1

- r-Value (AverEdge32 Recommended): ISO 10113, ASTM E517, JIS 2254, GB/T 5027

Plastic Standards

- ISO 527-2, ASTM D638, JIS K 7161-2, GB/T 1040.2

- Flexural Tests: ISO 178, JIS K 7171, GB/T 9341

Composite Standards

- ISO 527-4/5, ASTM D3039, GB/T 3354

Elastomer Standards

- ISO 37, ASTM D412, JIS K 6251, GB/T 528

Film and Foil Standards

- ASTM E345, ASTM D882, GB/T 1040.3

Enhanced Control

Streamlined operator settings are built directly into Bluehill® Universal software, allowing users to customize when the light bar and fans are active. This gives users greater control and convenience during setup and testing.

Data Rate

On-board measurement technology processes data in real-time (500 Hz), and is capable of meeting strain control requirements.

Quick Mount

Mounts easily on almost any Instron temperature chamber or universal testing equipment.

Automation Ready

Each AVE3 lens is configured and factory-calibrated to match your specific test setup, with locked aperture and focus settings to eliminate operator-induced variability.

Every lens includes a unique identification number, enabling automatic recognition by the test system through a precise kinematic connection, ensuring repeatable, accurate lens placement every time.

To simplify routine checks, the AVE3 also features a user-friendly calibration plate that clips directly onto the specimen, even with the load string in place. This makes it easy to perform periodic calibration and confirm that your system is always ready for reliable testing.

Image Credit: Instron - USA

Available Lenses

- 35 mm (Short Field of View): Appropriate for low-strain materials, including metals, composites, and filled or rigid plastics.

- 16 mm (Standard Field of View): Appropriate for materials like foils, metals, plastics, and sheet metals. The preferred lens for metals customers who need to monitor average transverse strain and manage strain rate (AverEdge32).

- 6 mm (Extra-Long Field of View) and 9 mm (Long Field of View): Appropriate for high-elongation materials such as films, rubbers, elastomers, and some plastics.

Image Credit: Instron - USA

Image Credit: Instron - USA

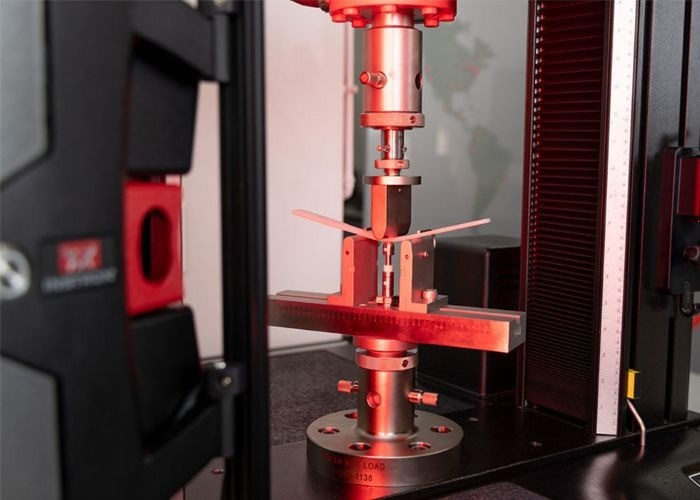

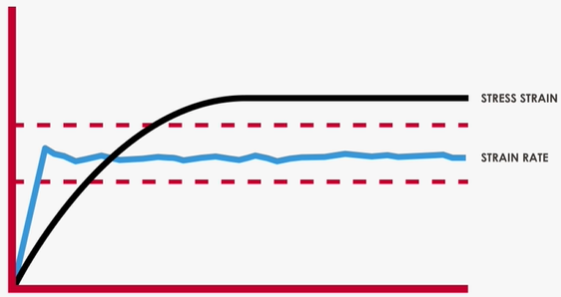

Strain Control

Real-Time Data for Responsive Strain Rate Control

Image Credit: Instron - USA

The new AVE3 makes it possible to perform strain-controlled testing in full compliance with standards like ASTM E8 and ISO 6892. With enhanced accuracy and a high-speed data capture rate of 500 Hz, the system delivers fast, reliable insights, allowing real-time response to changes in strain rate. This ensures your results are not only repeatable and consistent but also fully aligned with the latest testing requirements.

Download the Brochure for More Information

Advanced Capabilities

Optional Add-Ons

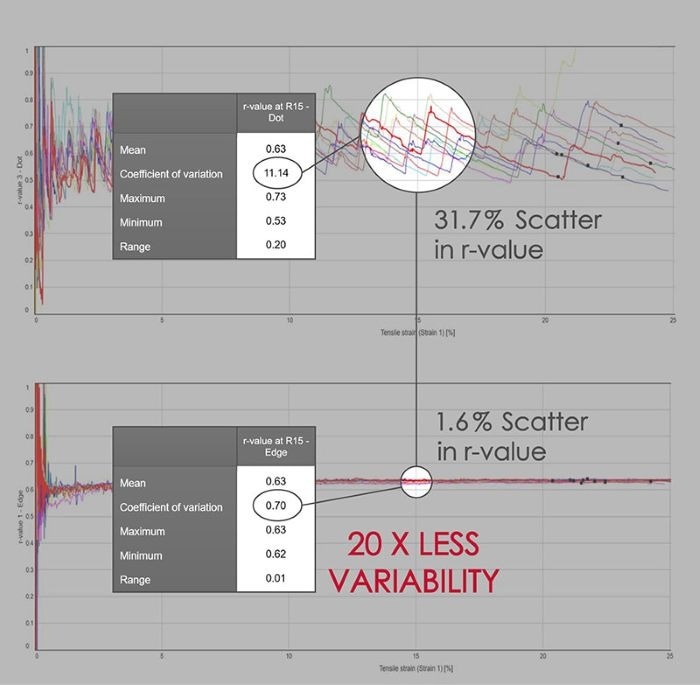

AverEdge32™

Advanced Averaging Transverse Strain Measurement for Sheet Metal

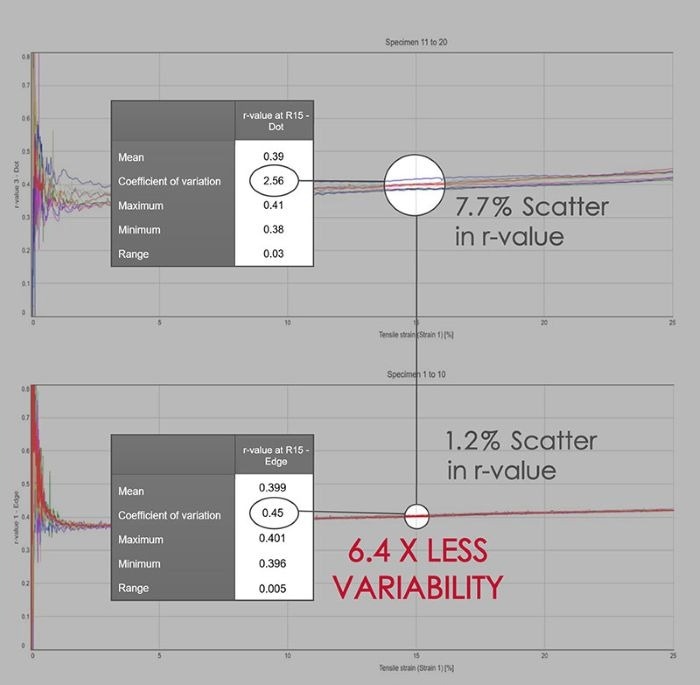

AverEdge32 is an optional advanced feature of the AVE3 that leverages edge-detection technology to measure transverse strain at 32 points along the specimen gauge length, simultaneously and in real time. Averaging these measurements instantly provides a smooth, highly repeatable transverse strain value, which is critical for accurately calculating the r-value in sheet metal testing.

AverEdge32™ | Advanced Averaging Transverse Strain Measurement for Sheet Metal

Video Credit: Instron - USA

Features:

- Edge detection eliminates the need for transverse marks.

- Exceeds the requirements of ISO 10113, ASTM E517, JIS 2254 & GB/T 5027 for plastic strain ratio (r-value).

- Improved results repeatability, reducing or eliminating the need to perform retesting.

- Real-time transverse strain, averaged from 32 gauge widths, provides repeatable transverse strain with even the most demanding materials.

r-Value Comparison

Single Gauge Width vs. AverEdge32 Technology

5000 Series Aluminum. Image Credit: Instron - USA

6000 Series Aluminum. Image Credit: Instron - USA

Download the Brochure for More Information

Digital Image Correlation

Optional Add-On for Full-Field Strain Mapping

Digital Image Correlation (DIC) is an optical technique that compares images of a tested specimen's surface to generate full-field strain and displacement maps. It creates pictures that can be used to visualize strain and displacement over the full two-dimensional surface of the test specimen.

DIC Enables:

- Analyze strain and displacement on the flat surface of a part or component where traditional extensometers are impractical.

- Check for standards compliance by identifying localized strain that falls outside of the standard gauge length.

- Check specimen preparation techniques by comparing one specimen to the next.

- DIC software communicates directly with Bluehill Universal for easy transition from test to data review.

- View materials testing phenomena, such as discontinuous yielding, localized necking, and more.

- Visualize and detect cracks that are not visible to the eye.

- Visualize the side profile of a flat flexure or compression specimen to observe strain behavior.

Digital Image Correlation (DIC) Software for Non-Contacting Strain Measurement

Video Credit: Instron - USA

Unparalleled Performance

- The latest generation CDAT technology improves accuracy up to 5x (Compared to a video extensometer without CDAT technology)

- Dynamic cross-polarized lighting

- Data capture rate: 500 Hz

- 6 mm, 9 mm, 16 mm, and 35 mm focal length lens options for a field of view up to 685 mm

- Strain control capable

- AverEdge32 compatible for transverse strain measurement (optional)

- Digital Image Correlation (DIC) software compatible (optional)

- Designed for static testing applications