UK based Perpetuus Carbon Group and G24 Power Ltd have entered into a Memorandum of Understanding, a precursor to a full commercial partnership and manufacturing agreement.

Both companies are big players in their respective fields; Perpetuus are the largest producer and supplier of functionalized, high-quality graphenes in the world, whilst G24 are a renowned authority in the dye sensitized solar cell (DSSC) market with expertise and knowledge in the production of conductive, multifunctional multilayer coated webs.

Perpetuus will supply G24 with functionalized graphenes which will then be used to manufacture a variety of “advanced graphene enabled components”. These will be in either sheet or roll form.

With highly advanced manufacturing equipment, G24 can achieve a production capacity of 1000’s of meters of components per month. These components can be applied in a number of areas including:

- Resistance heating

- Bio-sensor platforms

- Barrier packaging

- Composite physical reinforcements

- Water treatment

- Proton Exchange Membrane (PEM) Fuel Cell

- Thermal management and heat dissipation

- EMI shielding

- Electrodes for batteries and super capacitors

- LI-AIR battery cathodes

The rolls produced will have a thermal conductivity of over 500 W/M°K and a surface resistivity substantially lower than 1 Ω/sq. They can be manufactured in specific thicknesses, on specified substrates for components to be used in the aerospace, marine, automotive, energy generation and energy storage industries.

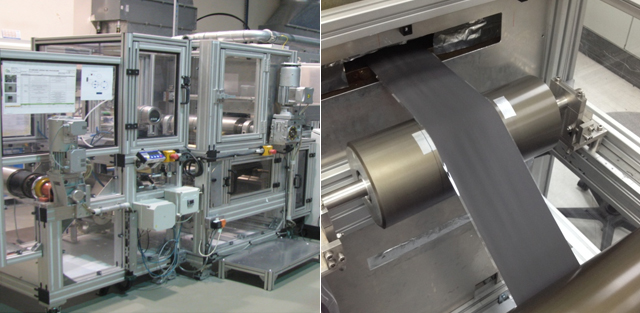

Left: Roll-to-Roll Coating Equipment. Right: Graphene Enabled Coating on 300mm Sheet. Image Courtesy: G24 Power Ltd

Perpetuus and G24 will both be exhibiting some of these graphene-enabled components on 19-20th of November 2014 at IDtechEx Graphene Live! as well as Printed Electronics USA 2014 in Santa Clara, California. Experts from both companies will be on hand to discuss customer requirements and specifications in detail.

For more information on IDtechEx Graphene Live! including details on how to register, visit their website here.

John Buckland, CEO of Perpetuus Carbon Group said,

“We were impressed how quickly the technical team at G24 took our graphene enabled compounds and started producing components that can be used in so many exciting areas of industry.

Their manufacturing equipment and scientists are first class and I have no doubt our partnership will quickly make us the world’s first manufacturer of graphene enabled components in many market sectors. This new relationship, together with other collaborations sets Perpetuus Carbon Group apart from our competitors as the only business truly able to commercially produce graphene enabled products.

Our existing and soon to be expanded facility in South Wales, UK, has the capability to grow into the world’s first centre for manufacturing graphene enabled products. Taken together with exciting advances in R&D at the Institute of Graphene at Manchester University, we believe that George Osborne’s vision of the UK being the powerhouse of graphene technology will soon become a reality”.

Richard Costello, CEO of G24 Power said,

“G24 are known the world over for excellence in the field of DSSC PV technology. Our expertise in this regard has delivered a capability to produce high-speed, roll-to-roll, precision thickness coatings. Working with Perpetuus we have configured our production equipment to manufacture graphene-enabled coatings and films to precise specifications.

We can therefore produce to order a range of components and applications for the automotive, aerospace, marine, electronics, as well as other market sectors. With Perpetuus producing commercial quantities of functionalised graphenes we are perfectly placed to supply the global market with these exciting new products.”

Developments in Graphene Production

Graphene production has until recently been very limited (ouputs as low as a few grams per week). This has resulted in very high prices for graphene consequently making it one of the most expensive materials known to man.

Researchers and industry professionals alike all experience the same problems when it comes to using graphene; the material is expensive, hard to find at high quality in large quantities, and has an inherent tendency to agglomerate, causing significant reductions in the surface area of the material. These issues often mean that the graphenes they source cannot be processed.

Perpetuus have created a new way to produce graphenes known as the dielectric barrier discharge plasma method. This innovative technique solves previous problems and allows for the production of friable sub stacks of single, hi- and tri-layer graphenes with nano engineered surfaces, enhanced with the functionalities that provide both ease of dispersion and covalent bonding within any chosen matrix.

Located in South Wales, UK, the Perpetuus manufacturing facility is capable of producing over 100 tonnes of graphenes per annum. It also remains the only graphene production facility worldwide which has been independently verified - carried out by experts from Scott-Grant and Auditors Grant Thornton in August of 2013.

About Perpetuus Carbon Group Ltd

For any company to be successful in the commercialisation of graphene materials they need to offer ALL the following features to a customer:

- Functionalisation by implanting a variety of chemical groups onto and within graphenes to nano surface modify graphene to customer specifications.

- Reliable and consistent supply of high quality graphenes for R&D.

- Immediate availability of materials in grams and kilos.

- Rapid delivery of tonnes rather than grams.

- Production in Commercial quantities.

- Competitive pricing.

- An environmentally friendly production process (this will become more relevant as the industry expands).

- Environmental impact studies and life cycle analysis on all outputs and by-products.

- Comprehensive and reliable characterisation data.

- Manageable, transportable, user-friendly graphene presented in ‘stacks’. (Graphenes as single layers are invisible to the naked eye and cannot be packaged or handled).

Perpetuus offer all the above to its customers. Perpetuus are not aware of any other business in the world who can offer the full range of these goods and services to its customers and therefore we believe, we, a British Company, are the world’s leading producer and supplier of high quality nano surfaced engineered graphenes.