A recent article published in Small Science introduces fully bioderived, four-dimensional (4D) printable shape memory polymers (SMPs) with linear tunability and remotely controlled actuation capabilities.

These polymers are derived from renewable plant-based acrylates, including acrylated rapeseed oil (ARO), isobornyl acrylate (IBOA), and isobornyl methacrylate (IBOMA), offering both environmental sustainability and functional adaptability.

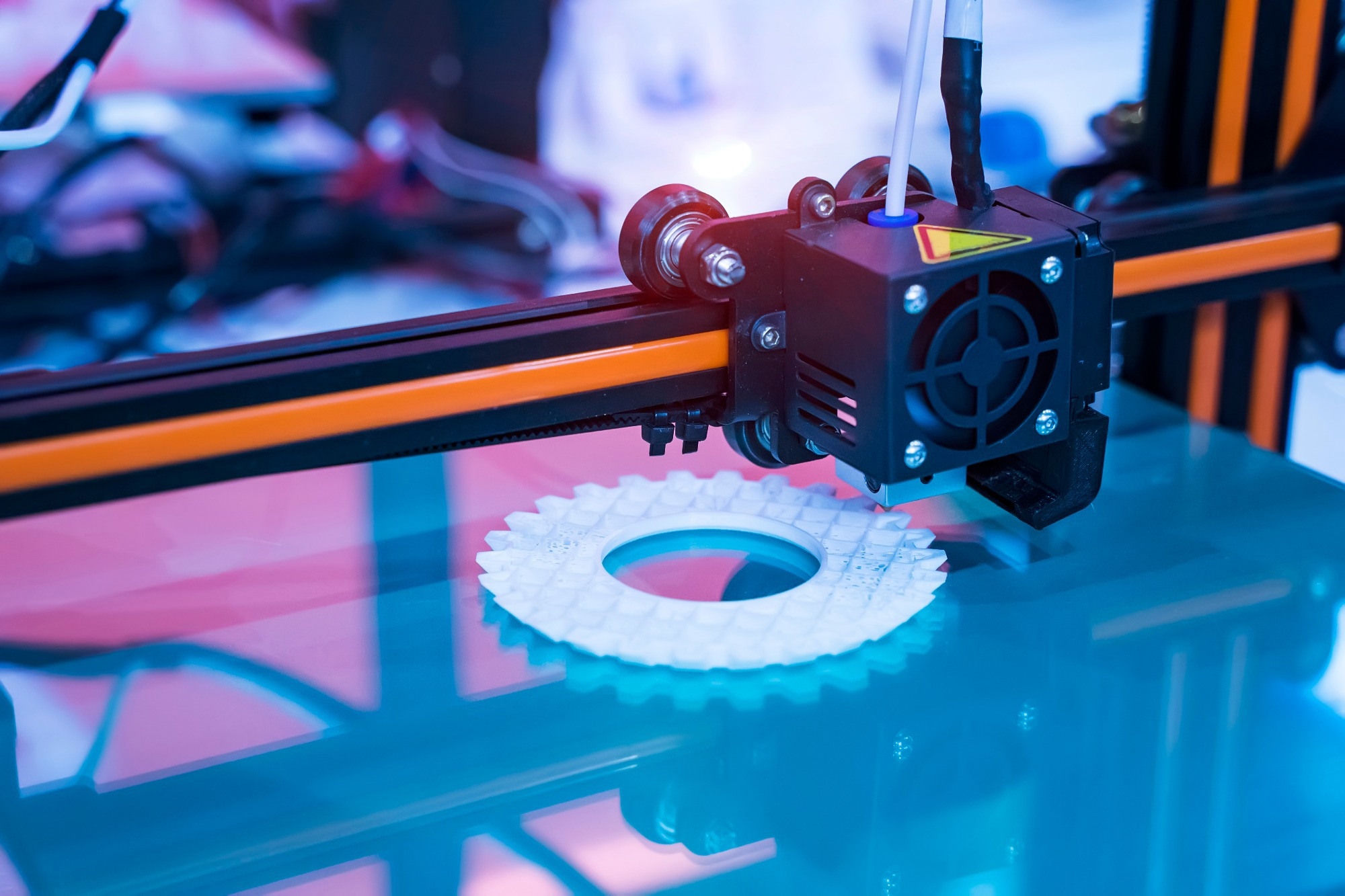

Image Credit: asharkyu/Shutterstock.com

Background

The rapid growth of smart materials and 3D printing technologies has led to breakthroughs in robotics, biomedical devices, and adaptive surface engineering. Among these materials, shape memory polymers (SMPs) stand out for their ability to “remember” and return to a programmed shape when exposed to external stimuli.

Despite their potential, traditional SMPs are mostly derived from petroleum-based sources, which limits their biodegradability, renewability, and alignment with sustainable practices. Biobased SMPs offer a promising alternative. Although recent developments have introduced tunable biobased SMPs, scaling them for use in 3D-printed actuators remains difficult.

There has also been little research into SMPs that can reliably respond to more than one type of stimulus at the same time and are suitable for 4D printing.

To address this, the study presents a new fully biobased SMP system that is 4D-printed using vat photopolymerization (VPP) and can respond to hot air, light, and electric fields.

Methods

Researchers synthesized ARO from rapeseed oil and acrylic acid to create ultraviolet-curable biobased resins. These were mixed with IBOA, IBOMA, 2,2-azobis(2-methyl-propionitrile), and varying amounts of carbon nanotubes (CNTs). For conductive composites, single-walled CNTs were added.

The materials were 3D printed using a digital light processing (DLP) printer. The printed resins were cured for five minutes (neat resins) or 10 minutes (composites). Before printing, photorheology was used to measure resin viscosity, and curing depth was tested for both neat and CNT-filled resins.

Fourier-transform infrared spectroscopy (FTIR) was used to examine chemical interactions in both raw and printed materials. Mechanical testing included tensile tests and measurements of storage and loss moduli using dynamic mechanical analysis (DMA), which also assessed the shape memory effect.

Thermal conductivity was measured using the laser flash method, while electrical resistance and Joule heating were tested using thermal imaging and a custom setup. To demonstrate actuation, 4D-printed structures were triggered using hot air, electrical power, or light, after being manually deformed and heated above their glass transition temperature.

Results and Discussion

The 4D-printed SMPs exhibited a linear activation temperature range from 32 to 76 °C, with excellent shape fixity and shape recovery ratios of up to 99%. The mechanical properties of the materials were also tunable, with tensile strengths ranging from 2.3 to 12.5 MPa.

While the inclusion of CNTs initially reduced curing efficiency and mechanical performance, these challenges were effectively addressed. As a result, the composites successfully achieved both electrical and light-induced actuation, allowing for localized and precise control of the shape memory effect.

To demonstrate functionality, several complex structures were 4D-printed using the biobased SMPs.

For example, a spiral model printed from two thermomechanically distinct materials showed different actuation speeds at the same heating rate. The softer spiral activated and returned to its original shape in approximately 10 seconds, due to its lower activation temperature.

In contrast, the spiral with higher methacrylate content required more heat and time due to steric hindrance caused by the methacrylate groups. A hybrid spiral structure combining both materials showed sequential actuation during heating.

In a separate demonstration, a 1-mm-thick, 90-mm-long 4D-printed bar was successfully actuated using light. The structure recovered its original shape in about 10 minutes, a duration that could be significantly reduced by optimizing laser placement and beam size for more efficient, uniform heating.

Download your PDF copy now!

Future Prospects

The developed SMPs exhibited rapid multistimuli responsiveness. The successful 4D printing of complex structures also underscored their potential for applications requiring programmable functionality and dynamic shape changes. Therefore, the proposed SMPs can be sustainable alternatives to petroleum-based materials.

Further optimization of these biobased SMPs could drive advancements in responsive systems for medical devices, soft robotics, and industrial applications. Future work should also focus on developing degradation and recycling strategies to address the inherent limitations of thermosetting, crosslinked polymers.

Journal Reference

Jurinovs, M. et al. (2025). Sustainable 4D Printable Biobased Shape Memory Polymers with Linear Tunability and Multistimuli Actuation for Advanced Applications. Small Science. DOI: 10.1002/smsc.202500104, https://onlinelibrary.wiley.com/doi/10.1002/smsc.202500104

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.