Nickel-titanium (NiTi) shape memory alloys (SMAs) are unique metal alloys that can be stretched or bent when cold and hold the shape only to return to their original shape when heated. This makes NiTi SMAs useful for a wide-range of devices: surgical implants, anti-scald valves, motorized actuators, and more. Because SMAs respond to heat, researchers rely on infrared cameras to help better understand their behavior.

FLIR X8583 camera. Image Credit: FLIR

FLIR X8583 camera. Image Credit: FLIR

The Challenge: Capturing Non-Uniform Thermal Behavior in Complex Materials

NiTi SMAs are among the most promising materials for solid-state refrigeration technologies, thanks to their remarkable elastocaloric effect (eCE) and superelasticity. However, accurately characterizing their thermal behavior especially under mechanical stress remains a complex challenge.

“It is well-established that the temperature of some special shape memory alloys varies under applied stress,” explains Dr. Ruien Hu, Scientific Officer at PolyU. “We previously used thermocouples to measure temperature changes, but their single-point measurement capability was insufficient to capture the nonuniform temperature distribution across specimens particularly given the heterogeneous nature of NiTi alloys.”

The Need for Full-Field, High-Speed Thermal Imaging

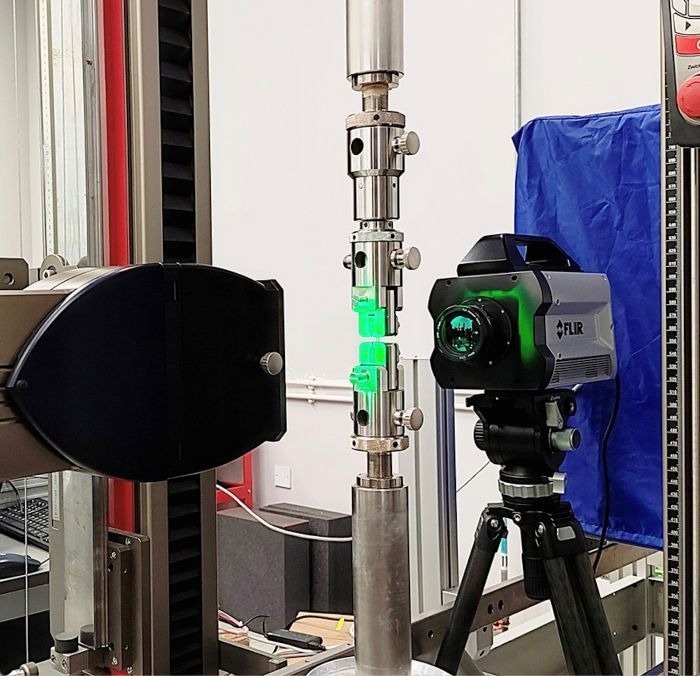

To overcome these limitations, Dr. Hu and his team turned to FLIR for an appropriate science-level infrared camera. They chose the FLIR X8583, a midwave, high-speed camera equipped with advanced lenses, filters, and software.

“Our experimental setup involves using a tensile testing machine to conduct tensile and compression tests on shape memory alloys,” says Dr. Hu.

“Simultaneously, the FLIR camera records and analyzes the temperature variations under stress. This capability is essential for understanding the elastocaloric response.”

The FLIR X8583 camera offered the high-speed, 1280 × 1024 thermal imaging the team needed to visualize inhomogeneous surface temperature distributions during mechanical loading cycles offering insights that traditional sensors could not provide.

Scientific Discovery: Microstructure-Driven Thermal Inhomogeneity

In a recent study, the team used Laser Powder Bed Fusion (LPBF) to fabricate NiTi alloys with nearequiatomic composition. They discovered significant inhomogeneity in the elastocaloric effect, with up to 4.2 K temperature difference across a single sample.

“Infrared imaging revealed that the surface temperature distribution was inhomogeneous during compression-induced elastocaloric effects,” Dr. Hu notes. “This was mainly due to the non-uniform microstructure of the NiTi alloys fabricated by LPBF.”

FLIR’s thermal imaging captured striped high- and low-temperature regions, helping the team link grain size, dislocation density, and precipitate distribution to the functional performance of the material.

Testimonial: The FLIR Advantage in Research

“The high resolution of the FLIR infrared camera is particularly advantageous for our research, as our specimens are relatively small. Additionally, the camera's exceptional frame rate allows us to capture rapid temperature changes with precision critical for our analysis. FLIR has significantly enhanced our experimental capabilities, enabling us to uncover the intrinsic thermal behavior of our specimens with greater detail and accuracy,” says Dr. Hu.

Outcome: Enhanced Understanding and Scientific Impact

With FLIR’s powerful tools, the research team was able to:

- Identify the role of microstructural inhomogeneity in temperature distribution

- Capture full-field thermal responses during cyclic mechanical testing

- Gain new insights into super elasticity and functional fatigue

- Demonstrate 96.1% recovery after the first cycle evidence of excellent super elasticity

These findings are contributing to a broader research initiative to advance solid-state cooling technologies and adaptive material design.

Support and Future Exploration

The team also credits FLIR’s technical support in their success:

“We’ve greatly benefited from the guidance of FLIR representative Mr. Liu Yongbo, who helped resolve several technical challenges. We look forward to continued collaboration and support as our research evolves.”

Dr. Hu and his team are also interested in participating in FLIR user conferences and scientific forums to share insights and foster collaboration within the research community.