Chemists use synthesis to create substances with engaging properties, from medicines saving millions of lives to organic emitters that light the screens of smartphones.

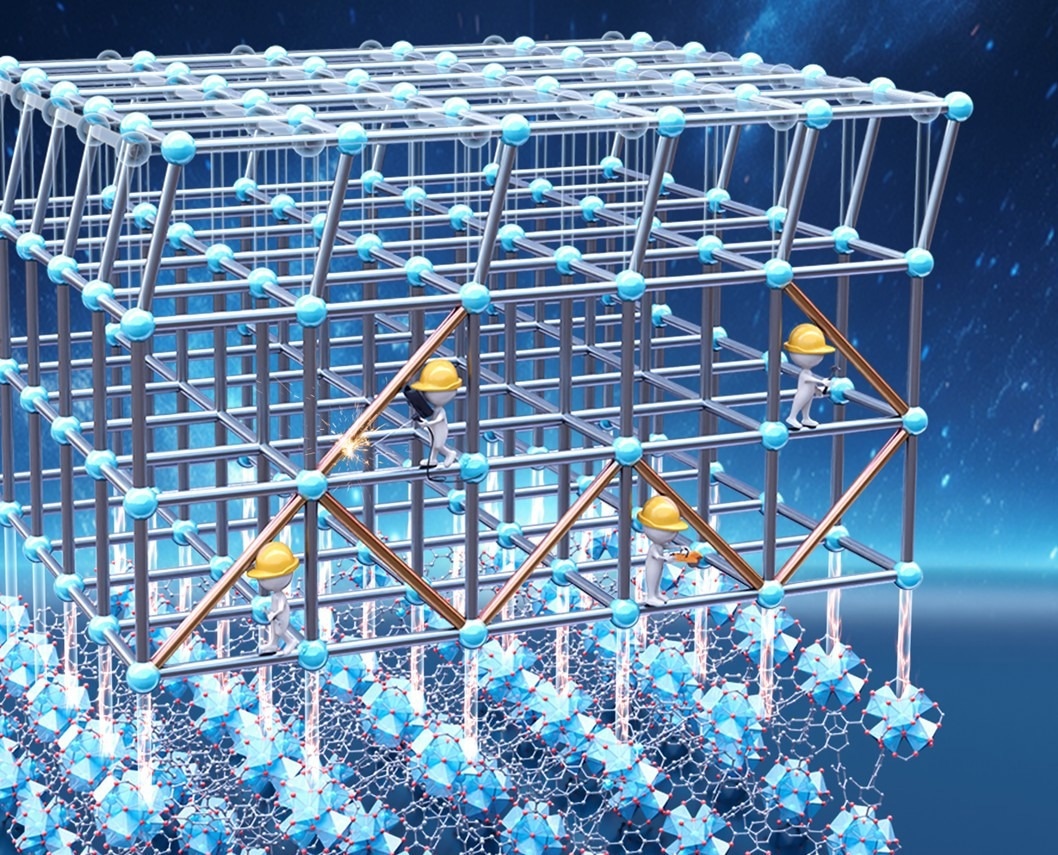

Study: Chemical Construction of Molecular Truss Lattices with Tunable Topologies. Image Credit: Kun-Yu Wang

What if we could also engineer mechanics: the manner a material bends, twists, and resists force, using the tools of synthetic chemistry?

That question was recently answered in a paper from the University of Pennsylvania.

Researchers developed a metal-organic framework (MOF), a porous material that won the 2025 Nobel Prize in Chemistry, assembled from molecular building blocks, which enables structural deformation through the bending and twisting of chemical bonds.

Here, chemistry becomes an architect at the sub-nanometer scale, precisely constructing a periodic lattice structure with a macroscopic mechanical response. This research offers more than a new tool for materials scientists: It hints at an idea that chemistry can also contribute to mechanical material design, an area traditionally dominated by engineers and physicists.

Read about the Nobel Prize winners here

Chemists as Molecular Architects

Mechanical metamaterials, whose exotic properties mainly arise from structural connectivity, can display negative Poisson ratios, absorb shock, and guide sound propagation.

As the field has focused on design and fabrication of these meta-structures using the state-of-the-art 3D printing and lithography, typically at the micrometer scale or larger from the off-the-shelf materials, building periodic lattices in 3D with precision, especially with molecular thin struts and nodes, is particularly challenging.

Chemists are uniquely positioned to break that barrier. MOFs provide crystalline networks of metal “nodes” linked by organic “beams.”

By carefully swapping out those beams, which are linkers with linkers of different lengths and flexibilities, researchers could tune how the lattice itself responds to mechanical pressure, much like an architect choosing between steel or timber supports.

As a result, the stiffness of a MOF named PCN-700 (PCN stands for Porous Coordination Network) could be changed from roughly nine to 17 gigapascals simply by installing different organic linkers, while keeping the material’s low density.

The overall mechanical properties of these MOFs are comparable to those of light wood.

Deformation in Molecular Lattices

Researchers integrated experiments and modeling to see how these MOFs resist compression at the molecular scale. Surprisingly, PCN-700’s lattice is remarkably flexible.

Under compression, its chemical bonds can twist, bend, and rotate. The accumulation of countless tiny movements will yield the material’s visible shape change at the macro scale.

Why does this matter beyond our own curiosity? Because it challenges the long-standing assumption that chemists are suppliers of ingredients while engineers shape the final form.

If a chemist can build a lattice that absorbs or redirects mechanical energy at will, then chemistry is no longer just a source of materials.

Instead, it becomes a discipline of mechanical design. Imagine a future in which a capsule releases drugs only when it senses a patient’s muscle contraction, or a battery electrode stiffens as it charges to prevent cracking.

Such visions will not come solely from scaling down 3D printing, but they will also come from chemists who think like engineers while mastering tools to synthesize materials one molecular beam at a time.

Get all the details: Grab your PDF here!

Journal Reference

Wang, K., et al. October 2025, Chemical Construction of Molecular Truss Lattices with Tunable Topologies, Journal of the American Chemical Society, 38711, 147 (42) doi: 10.1021/jacs.5c13591

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.