Jul 24 2007

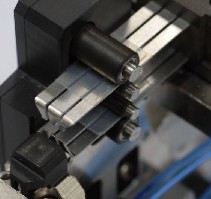

Victrex plc, a leading manufacturer of high performance materials, including VICTREX® PEEK™ polymer and VICOTE® Coatings, today announced that APTIV™ film, made with VICTREX® PEEK™ polymer, has been selected by ASM Pacific Technology, the world’s leading assembly and packaging equipment supplier, as a key component of its latest back-end Flexitest 2030 (FT2030) turret based test and finish system, a machine for testing the function and reliability of semiconductor chip solutions such as Discrete and Power devices before market shipment. Using APTIV film in several functional modules provides the new FT 2030 turret based test and finish system a number of performance benefits such as high wear and impact resistance, low volatiles, electrical stability and insulation and high potential test insulation of 1KV.

The newly launched APTIV™ film product powers ASM’s turret based test and finish system performance at the extreme speed required for back-end testing.

The newly launched APTIV™ film product powers ASM’s turret based test and finish system performance at the extreme speed required for back-end testing.

APTIV film has also been selected for use as the protective layer over the strip components of the test contactor module within the FT2030 test system. By incorporating the APTIV film layer over the contact strips, the contact strips benefit from longer lifetime and enhanced reliability. APTIV film’s wear and impact resistance at the extreme temperatures played a key role in its selection. ASM’s Flexitest test and finish system features 30 high speed turret pick heads for efficient processing of multiple process steps with extremely short index time and high flexibility.

“Components in our test handling systems need to be suitable for optimum performance in relatively harsh production environments.” explained Albert Sze, Project Manager, Test & Finish Handler Products at ASM Assembly Automation. “Our Flexitest 2030 system is designed for performing final tests for individual devices. Excellent insulation between the test contactor load board and the surrounding mechanical mountings is very important to ensure accurate test results, and as such requires a suitable film material to be incorporated as an insulative spacing sheet for the load board module. APTIV film fully met all of our criteria for this demanding application.”

“Building on its industry-leading track record with VICTREX PEEK polymer, this the latest iteration of the polymer into the films sector is a very exciting move for Victrex. Under the brand name APTIV,” said Edmond Chu, Regional Film Champion of Victrex Asia Pacific, “our film material is a technology enabler, offering many benefits to processors and OEMs, and further opening up a wide range of market segments, from electronics and aerospace, through to wire and cable insulation, and in semiconductor and automotive applications. In all cases, APTIV film can facilitate a reduction in systems cost, help improve performance, and enhance design freedom, all of which help our customers to improve their product differentiation. “

Based on VICTREX PEEK polymer, widely considered to be the highest performing melt-processable polymer available, APTIV film when compared with other film products available in the market is an extremely versatile and high performing product that delivers a broad range of capabilities under a diverse range of conditions.