By Muhammad OsamaReviewed by Lexie CornerJun 20 2025

By Muhammad OsamaReviewed by Lexie CornerJun 20 2025A recent study published in npj Materials Degradation introduces a two-stage machine learning (ML) framework that predicts the degradation of protective coatings under various environmental conditions.

By incorporating data on environmental stressors, changes in material properties, and corrosion indicators, the model offers a more accurate way to forecast coating failure.

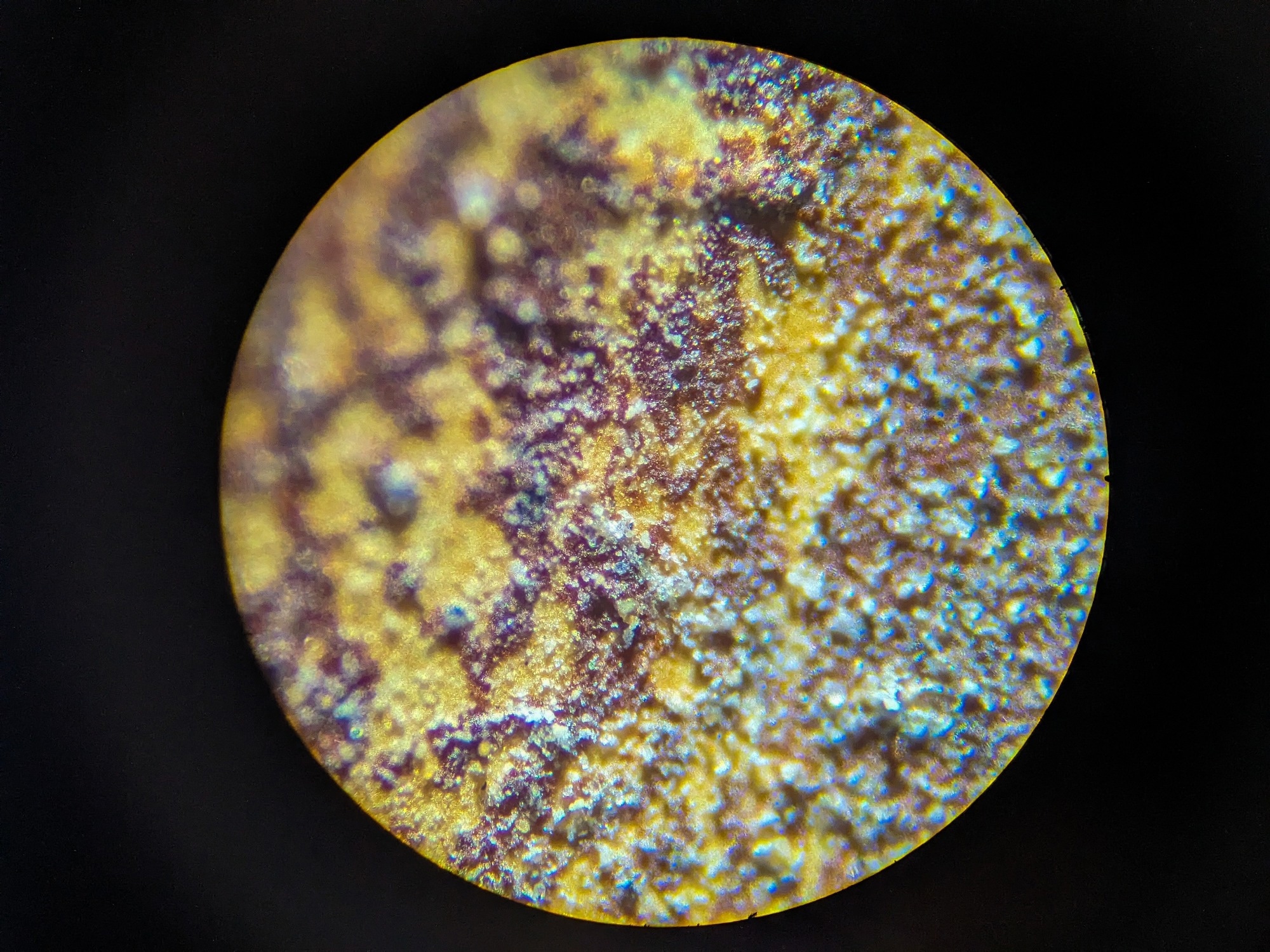

Image Credit: Mohammed_Al_Ali/Shutterstock.com

Image Credit: Mohammed_Al_Ali/Shutterstock.com

How the Environment Affects Coating Performance

Protective coatings—especially organic types like polyurethane (PU)—play a critical role in preventing corrosion on infrastructure. However, their durability is compromised over time by environmental factors such as ultraviolet (UV) radiation, humidity, and fluctuating temperatures. These stressors degrade key surface properties, including gloss, adhesion, and water contact angle (WCA).

Traditional empirical models often fall short in capturing the complex, nonlinear effects of climate on material degradation, partly due to limited real-world testing data. Recent ML advances, particularly in semi-supervised and classification algorithms, can better handle large, varied datasets even when labeled data are sparse.

Study Design and Data-Driven Modeling Approach

Researchers adopted a two-stage modeling strategy. In the first stage, PU coatings were exposed to outdoor environments for one year at nine different geographic locations—including Cairo, Jeddah, Singapore, and Islamabad. These sites offered a diverse range of environmental inputs, which were linked to changes in coating properties over time.

To analyze these relationships, the team developed a semi-supervised co-training regression model. Among the options tested, a reduced four-variable version of COREG (co-training regression with random forest) performed best, showing the lowest root mean square error (RMSE). This result underscored the value of selective feature filtering using Pearson correlations and importance rankings.

The second stage used the predicted material properties as inputs for a separate ML layer. This layer, which included support vector regression (SVR), artificial neural networks (ANN), and AdaBoost, estimated their link to corrosion failure. Electrochemical impedance spectroscopy (EIS) data served as the degradation benchmark. A binary classifier was also introduced to distinguish between damaged and intact coatings.

To improve model accuracy, the researchers added data from accelerated indoor aging simulations. These tests included UV exposure at 50 °C (60 W/m²) and salt spray exposure at 40 °C using 5.0 wt% sodium chloride, conducted over three two-day cycles. This added 37 new data points and boosted the model’s robustness. Feature contributions were interpreted using SHapley Additive exPlanations (SHAP), which highlighted adhesion as the most important predictor of corrosion resistance, followed by WCA and gloss.

Model Performance and Insights

The ML models achieved high accuracy. AdaBoost, in particular, delivered an R2 value of 0.83 and showed perfect precision in identifying coating damage. Models using fewer input variables outperformed those using full datasets, likely due to better generalization and reduced overfitting.

Environmental factors affected physical properties in distinct ways. Average temperature and humidity influenced adhesion and gloss, while UV exposure and air pressure played a larger role in yellowing.

The model also revealed site-specific differences: for example, coatings in Jeddah had the highest adhesion (6.97 MPa), while those in Cilacap—where humidity is high—had the lowest (4.03 MPa). Gloss values also varied by location, with Nepal showing the highest (22.14 GU) and Cilacap the lowest (8.00 GU).

The 4-CORF model consistently delivered the lowest RMSE in predicting physical properties, highlighting the benefits of targeted feature selection combined with semi-supervised learning.

Accelerated aging tests further confirmed that gloss, adhesion, and impedance modulus are positively correlated, indicating that coatings maintaining better surface integrity also resist corrosion more effectively. AdaBoost also proved strong in binary classification, reinforcing its usefulness for both performance prediction and damage detection.

Implications for Coating Design and Maintenance

This two-stage predictive system offers practical value across sectors such as marine, transportation, energy, and construction. It enables remote monitoring of coating performance, early damage detection, and informed maintenance planning.

In harsh environments—like deserts or coastal areas—the model can guide the selection of coatings tailored to local conditions. It also supports the development of next-generation coatings by clarifying how surface properties such as gloss and adhesion affect long-term durability.

Download your PDF copy now!

Looking Ahead: Data-Driven Corrosion Protection

The study presents a new machine learning framework that links environmental conditions, surface property changes, and corrosion failure in coatings. The two-stage approach outperforms single-stage models by better capturing complex degradation patterns. By focusing on the evolution of physical properties, the model offers a more precise understanding of how materials respond to their environment.

Future research could build on this by expanding the dataset to include longer exposure times, more environmental variables—such as pollutants or mechanical wear—and real-time sensor input. These improvements would further enhance model accuracy and support the creation of smart, self-monitoring coatings for resilient and sustainable infrastructure.

Journal Reference

Chen, W., et al. (2025). Prediction of coating degradation based on “Environmental Factors–Physical Property–Corrosion Failure” two-stage machine learning. npj Mater Degrad. DOI: 10.1038/s41529-025-00614-6, https://www.nature.com/articles/s41529-025-00614-6

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.