PolyVISIONS Inc is a speciality plastics companies, with a broad range of mixing and extrusion capabilities. The company is situated near New York. With more than 25 generic resin products that use numerous custom additives being processed at the company, there is a need for a heat transfer fluid that provides consistent thermal stability and undergoes minimum oxidation.

PolyVISIONS adopted Paratherm NF for its operations eight years ago, and continue to use it today. Paratherm NF has worked very well for PolyVISIONS‘ operations due to its non-toxic and non-fouling heat transfer.

PolyVISIONS inaugurated its current manufacturing unit at Manchester, PA in 1996. This unit employs 13 workers and produces over one million pounds of polyolefin and polyester compounds per year, generating $2 million in annual revenues.

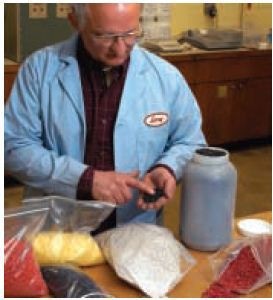

A number of manufacturers of end use compounds employ these speciality additive compounds to improve production process and product properties. The company supplies these speciality additives in a pellet concentrate form. Thorough, intensive mixing of the ingredients is the secret behind the high performance of these speciality pellets.

PolyVISIONS is capable of developing additives for various applications and incorporating the additives uniformly into plastic raw materials. Compounds in light powder forms are converted into pellets. The company also helps mitigate dust problems at customer production facilities by supplying compounds containing light powder ingredients.

Pigments, lubricants, surface modifiers for improved appearance, nucleating agents that promote crystallization of plastic compounds, and impact modifiers to impart more durability to plastic compounds are some of the additives used by PolyVISIONS.

Role of Paratherm Heat Transfer Fluids at PolyVISIONS

PolyVISIONS has a range of temperature control instruments from companies such as TUC, Delta T, and Advantage. Every PolyVISION unit uses Paratherm heat transfer fluids to maintain accurate temperatures.

The Readco Continuous Processor (Figure 1) is one of the processing machines at PolyVISION that was originally made for food processing application, but has been customized for processing PolyVISIONS’ plastic compounds.

Figure 1. Readco Continuous Processor Barrel Extruder equipped with Three Roll Sheet Stack. Temperature controlled with Paratherm heat transfer fluid.

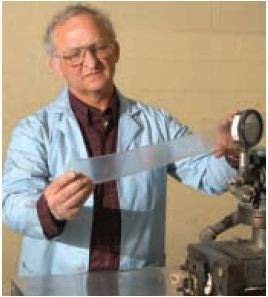

According to Larry Bourland, PolyVISIONS President and CEO, the equipment is especially helpful in blending compounds composed of light and powdery ingredients (Figure 2). High-density materials like pellets can be handled with conventional extruders. However, handling fluffy, low bulk density materials is a problem for such extruders, but can be handled by the Readco without any problem.

Bourland came across the Readco intermeshing, co-rotating twin screw equipment when attending a Penn State University conference in 1990.

Figure 2. Larry Bourland, CEO of PolyVISIONS Inc. inspects the quality of the extruded profile.

The Readco equipment was adapted to the operations at PolyVISIONS through a reconfiguration of components, including the drive train, internal elements, and segmented screws. The screw elements of the Readco have unusually deep flights, and therefore, large internal volumes.

As a result, shredded materials can be more effectively accommodated from recycled sources. Since the Readco was originally indented for mixing food formulations like candy and pasta, Bourland realized that the equipment can be adapted to blend the powdery ingredient used in the compounds processed at PolyVISIONS (Figure 3).

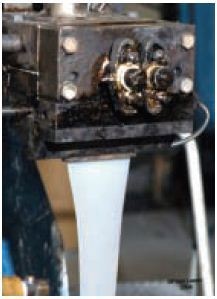

Figure 3. Intimate mixing of polymers by Readco Extruder equipped with vertical sheet die

According to Bourland, the Readco equipment can easily handle introducing the non-conventional feedstocks, mixing them in their molten state, and converting them into conventional solid pellets.

The Readco Continuous Processor (or CP) is equipped with a closed-loop thermal fluid system for circulating Paratherm NF, to maintain a pre-set temperature within the extruder barrel.

Since the deployment of the Paratherm fluid, it has been providing durable, hazard-free, and reliable service over the years.

Larry Bourland, CEO, PolyVISIONS Inc.

Bourland went on to say that carbon residue accumulation in the equipment is also drastically reduced using the Paratherm fluid, thanks to its superior oxidation resistance over competitive fluids.

The accumulation of carbon residue on the heating element surface negatively affects heat control. The results will be the same for residual coating on the surface of the pumps and cooling apparatus. At PolyVISIONS, temperature control is effectively achieved for applications of up to 550ºF using the Paratherm NF.

Figure 4. Larry Bourland demonstrates PolyVISIONS finished specialty additive products in pellet form

Electrical heat control can be achieved for even higher temperature applications using metallic bands as heating elements. However, an element of risk is involved with this direct heating method when an electrical arc is in the proximity of the airborne powdery substances.

However, with Paratherm NF, the external circulation of the heated fluid removes the risk of electrical arcs. Moreover, heat is more evenly distributed using the Paratherm NF when compared to electrical systems.

Furthermore, excess heat can be easily removed from thermal oil without any problem. The heat exchangers integrated into the temperature control units perform efficient removal of excess heat produced during melt processing.

Besides being used in the Readco CP, the closed-loop circulation of Paratherm NF heat transfer fluid helps achieve temperature control in other mixing equipment at PolyVISIONS, such as jacketed ribbon blenders, which perform solid-state mixing of materials. In this process, thermal fluid circulation takes place between the control mechanism and the blender at up to 350ºF.

Conclusion

All mix components are integrated more effectively and uniformly, thanks to the precise uniform temperature achieved using the Paratherm NF, leading to long production runs.

However, air exposure of the thermal oil can occur over a period of time, leading to oxidation of the fluid which compromises thermal performance. This means that routine maintenance is required to avoid downtime. Paratherm NF heat transfer fluid resists oxidation, and can, therefore, reduce the amount of maintenance required.

This information has been sourced, reviewed and adapted from materials provided by Paratherm.

For more information on this source, please visit Paratherm.