In the summer of 1970, the first summer job for Andy Andrews was to work on a paving crew. In those days, the equipment, as well as the labor for layering the prep, the screenings, and the asphalt surfacing, was not as specialized as it is at present. Andy Andrews was part of a crew laying country roads, as well as an occasional driveway, in rural Chester County, Pennsylvania.

The other members of the crew were a crew leader, two or three drivers and equipment operators, a foreman, and about 10 laborers. However, there was no project engineer as such. The owner of the company turned up now and then (at the time, he had a number of working crews) and grabbed a shovel himself. Aged 14 years, Andrews was the youngest, smallest, and the least of them by a great deal, in relation to capability and responsibility, specifically in terms of experience. The crew was rough-edged, but good-humored, and included workers of all ages, races and sizes.

Cooperative Work for Paving the Road

As soon as a stretch of road was prepped and ready, and a dump truck loaded with hot black asphalt mix came in, everyone got hold of a tool and started working. It was a controlled, collaborative commotion to correctly and cautiously tilt the dump bed; deposit a portion of the load; shovel, rake, and smooth the mix; and then steamroll it and progress to the next section. The workers used to sweat for about 20 minutes in the summer heat. After that, until the arrival of the next load, the speed of work was gradual when screenings were raked and other prep was done, and the workers briefed one another on their weekend conquests down the shore in Wildwood and drank ice water from the water jugs brought by the foreman. Although the hotness of the language was moderated for a 14-year-old, it was still considerably crude. At times, they used to send Andrews off to clean the encrusted asphalt cement from the shovels using kerosene.

The Asphalt Industry

Most Americans never think about the roads on which they ride when they drive from point A to point B. They might not understand that it is asphalt that literally paves the way for nearly every single person to reach their destination. Astonishingly, out of the 2.4 million miles of paved roads throughout the United States, about 2.3 million miles are paved using hot mix asphalt (HMA).

Until 2009, there were 3900 asphalt plants that produced 360 million tons of HMA, priced at 24 billion dollars. This industry is huge and looks indispensable, at least for the next five decades. Estimates show that 185 billion dollars will be needed to maintain the aging infrastructure of the United States, and HMA is going to take a very large portion of it. Since these 3900 asphalt plants in operation play a vital role in the lives of people, they have to remain functioning to their fullest always; any disruption could prove detrimental.

Hot-Oil Systems in Asphalt Plants

Andrews was not aware of these facts at that time, but around the time he had his first summer job, hot-oil systems — that indirectly heat different equipment at asphalt plants — were being rapidly substituted in the place of emissive and inefficient direct-fired heating, thereby enabling plants to increase the viable storage time of prepared hot-mix asphalt. Currently, almost every plant has a hot oil system for heating the asphalt cement — around hundreds of thousands of tons of it across North America. The use of cheaper oils can cause not only serious problems in a system in the long run but also delays. Multi-purpose oils such as those are not developed to carry out the continuous heating functions required by HMA plants. In contrast, engineered heat transfer fluids are particularly formulated for continuous high-temperature systems and do not tend to fail like multi-purpose hydraulic or lubricating oils.

Present-Day Asphalt Plants

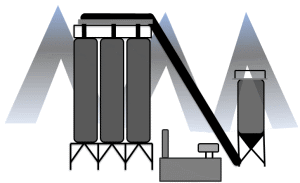

In this industry, specifications, limitations, and calculations have become more and more important. Since the insulated trucks can keep the mix hot and workable only for a particular period of time, the practical limit for the distance from the plant to the job is about 50 miles. This is the reason for the 3900 asphalt plants to be literally scattered all over the country. This means that the average Americans traveling from point A to point B have come across asphalt plants hundreds of times, and might in fact see them every day without their knowledge. Asphalt plants have a unique appearance with a few telltale visible characteristics — pyramid-like piles of gravel (or the aggregate), a slanted conveyor that moves the aggregate, and tall cylindrical structures which are either storage silos or asphalt cement tanks. In 1970, when Andrews briefly worked on a paving crew, he could even see the smoke billowing from the stacks of the plant. Nowadays, emissions are quite well-controlled and regulated.

Maintaining a Program According to Seasons

As known by anyone in the industry, this business is seasonal — in cold climatic conditions, operation and paving are carried out from the spring until late fall because paving cannot be performed efficiently below 40 °C. This off-season is the optimum time to preserve the heat transfer fluids and keep them working optimally; however, during the season, time is crucial. Maintaining a program of regular checks — such as practicing shut-down procedures, checking insulation, cleaning equipment, and performing fluid analysis — will ensure that when spring arrives, everything works perfectly.

Chemical analysis of the heat transfer fluid, which is generally termed “the hot oil” in this industry, is specifically crucial when the cold season approaches. If a hot-oil system is operated continuously for a number of months and the fluid has considerably degraded due to overheating or oxidation, the heat transfer fluid could in fact get solidified upon finally shutting down the system. Moreover, dismantling a hot oil system could prove to be an expensive way to change the oil. If a cooled sample of hot oil doesn’t flow, one must proceed with caution; the circuit must be kept hot until consultation with the manufacturer of the fluid or the heater.

Conclusion

When the complete road transportation system of the United States is dependent on the performance of HMA plants, it is vital to ensure the right kind of heating.

This information has been sourced, reviewed and adapted from materials provided by Paratherm.

For more information on this source, please visit Paratherm.