Quantifiable texture analysis of dairy foods is an evolving area of quality assurance that is yet to reach its full potential. Such a measure using a Texture Analyzer, employed across a range of dairy products and packaging, can provide manufacturers with the peace of mind that their dairy products meet consumer expectations and are consistently functional, practical, and appealing. From yogurt separation to cheese crumbliness and even the effectiveness of dairy product packaging, changeable raw materials and sensitivity to handling mean more risk of a batch to batch variations in textural properties. With the consumer in mind, these issues must be monitored and measured strictly, so that only the best quality products end up on supermarket shelves.

Instrumental texture analysis combined with sensory expertise is an essential objective tool for the identification and measurement of subjective textural characteristics. Offering a broad range of repeatable, objective analyses of product quality and texture, Stable Micro Systems allows dairy manufacturers to scrutinize the production process from stage to stage and produce optimal, consistent results.

Typical Texture Analysis Tests for Dairy Products

How to Measure the Consistency of Semi-Solid Dairy Products

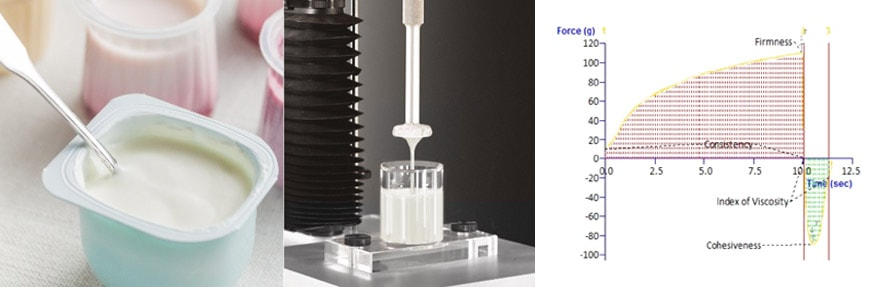

Yogurt and related fermented products are found in almost every society. In addition to yogurt, crème fraiche, whipped, sour, and clotted creams and mousses, as well as savory dips, all fall under the semi-solid category. Not only are these products already hugely popular – they are continuing to develop and diversify at great speed. The texture of these products varies widely, depending on the milk source, the microflora used, and the presence or absence of sweeteners, fruit, etc. There are also additional parameters such as pH and total solids which can affect the stability and textural aspects. Smoothness, firmness, creaminess, consistency, and viscosity are terms that are used to describe the texture of yogurt products with syneresis, lumpiness, and graininess being undesirable textural characteristics.

Analyzing the texture of unsupported structures such as these is important, as it can provide manufacturers with vital information as to a product’s consistency throughout its shelf life, which can vary drastically as the active ingredients begin to ferment. In addition, it offers a valuable comparison between different products hoping to achieve the same consistency, for example, full fat and reduced-fat mayonnaise.

A Back Extrusion Rig offers an invaluable measure of product consistency. A sample container of the test matter is compressed by a disc plunger attached to the TA.XTPlus Texture Analyser, which extrudes the product up and around the edge of the disc. The effort taken to do this is measured and results give an indication of viscosity. Such a measure relates to the body of flowing nature of the product, its mouth-coating potential, and spoonability.

Back Extrusion Rig and a typical comparison of full vs. low fat yoghurt

How to Measure Spreadability and Stickiness

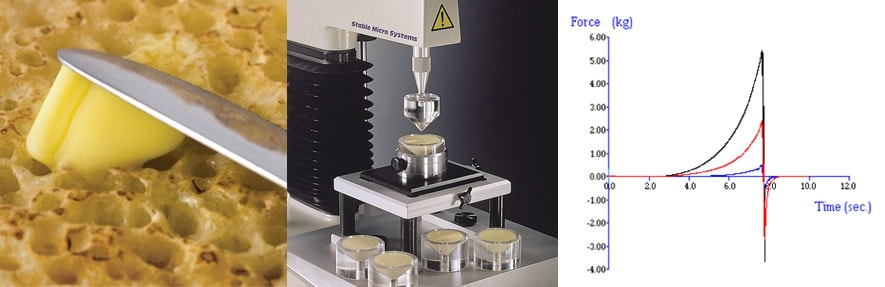

Many people are interested in measuring the spreadability of food products such as butter, spreads, peanut butter, margarine, cheese, and cream cheese. It is apparent that there is now a variety of dairy products on the market with a wide range of spreadability properties. These products are often very shear sensitive and are difficult to consistently prepare for testing. Penetration and compression style tests are simple methods that give results of sample hardness. Hardness measurements, however, even with cone probes, are not always good discriminators of spreadability.

The Spreadability Rig is an attachment that measures the ease with which a product, such as margarine or table spread, can be applied in a thin, even layer. It comprises of a male 90° cone probe and five precisely matched female perspex cone-shaped product holders. The material is either deposited and allowed to set up in the lower cone holders in advance of testing or is filled with a spatula and the surface then leveled. Excessive work is not introduced into the product and as long as the material has not been excessively worked, different styles of filling the material only affect the early part of the test.

Spreadability Rig and a typical comparison of 3 fat types

During the test, the force is seen to increase up until the point of maximum penetration depth of the cone probe. This peak force value (maximum force to shear) can be taken as the “Firmness” at the specified depth. The probe then proceeds to withdraw from the sample and any adhesive characteristics are indicated by a negative force region on the curve.

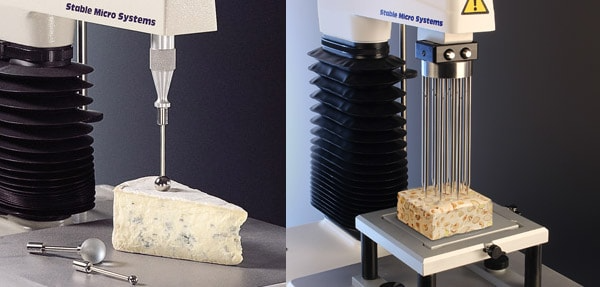

Measurement of Firmness/Hardness

Cheese accounts for the largest proportion of overall volumes of production in the dairy sector. A global commodity, it is most commonly sold in block (wrapped) form. Several tests on cheeses are available to measure their firmness and hardness, which is essential in dictating how they will cut or grate, how much they ripen during their shelf life, and, as a result, how they should be packaged.

The firmness/hardness of cheese is assessed in several different ways by a consumer

Testing cheese hardness using a Grating Rig, Wire Cutter or Fracture Wedges

Testing cheese hardness using a ball probe or Multiple Puncture Probe

Possible Cheese Testing Methods

Using a Grating Rig – A block of cheese can be pressed against a grating face under a chosen weight. The movement of the arm then provides the necessary pulling action to grate the cheese and the forces to do this are measured imitating the ease of difficulty a consumer would experience when grating.

Using a Wire Cutter/Knife Blade – A simple cutting test will measure the force required to cut through the cheese and demonstrate the firmness and consistency of a cheese, and can also be used for butter and block ice creams.

Using Fracture Wedges – Measuring the firmness, hardness and brittleness of a cheese is also essential in order to assess its crumbliness, springiness and elasticity. Fracture Wedges will provide these measurements by quantifying ‘force to fracture’ measurements. One upper and one lower wedge, each with a cutting angle of 30˚, is connected to the load cell and the base of a TA.XTplus Texture Analyser respectively. The wedges cut together and the force to fracture gives a measurable indication of the cheese’s composition and strength.

Using Penetration testing – A small distance penetration test of uniform products using a spherical probe can measure the surface hardness, as well as the ripeness, of a cheese. In addition, by measuring the force required to puncture the surface of a cheese by penetrating to a greater distance, comparisons can be made between its inner and outer firmness.

Using a Multiple Puncture Probe – The Multiple Puncture Probe allows food manufacturers to test non-uniform products containing particulates of different sizes, shapes, structures, and levels of hardness, to provide repeatable results. Such products have non-homogeneous textures due to the presence of, for example, dried fruits, vegetables, or nuts or consist of different layers to provide more interest to the consumer. By penetrating the product in several areas at the same time, the Multiple Puncture Probe produces an averaging effect and is, therefore, more representative.

Measurement of Extensibility/Stringiness

The extensibility of cheese is an important textural characteristic in a wide range of food applications. Freezing, shredding, thawing, and even cooking cheese can have a significant impact on its textural characteristics. Reduced-fat products also display very different characteristics compared to full-fat versions. All of this may result in a texture with an undesirable mouthfeel.

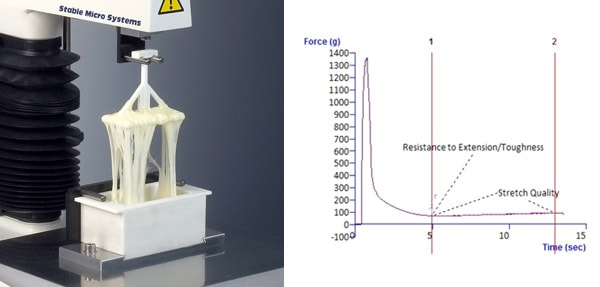

The Cheese Extensibility Rig comprises a microwavable vessel, sample retainer, and double-sided fork probe. The cheese is microwaved in the vessel until molten. The arm of the Texture Analyser pulls the fork upwards through the molten cheese and the force required to stretch the cheese and the distance to breakpoint is measured. Typical results show that the longer the distance, the stretchier the cheese. For repeatability and replication of consumer experience, a PT100 temperature probe may be used to monitor the temperature of a sample and programmed to start when a chosen target temperature is attained.

Measurement of molten cheese extensibility and a typical graph

This article only covers a selection of typical tests for dairy products but other methods are available for the measurement of e.g. extrudability, Texture Profile Analysis (TPA), packaging integrity.

For a full summary of typical texture analysis tests that can be performed on products:

Dairy Product Texture Measurement & Analysis

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.